Because the scientists at Bell Labs invented the world’s first transistor in December 1947, a revolution in microelectronics know-how has profoundly affected existence worldwide. As electronics get smaller and smaller, it’s a problem to search out a simple, quick, and low-cost method to fabricate micro-nano elements. Conventional direct writing fabrication strategies corresponding to mechanical scribing, targeted ion beam etching, electron beam lithography, multiphoton polymerization, and thermal scanning probe etching are inefficient.

Though strategies corresponding to nanoimprinting, photolithography, plasma etching, and scanning laser interference etching can successfully improve the processing velocity, they often require a number of course of steps corresponding to making masks or require very harsh working environments and depend on particular supplies.

Utilizing a femtosecond laser to induce floor self-organized periodic construction to fabricate nano-grating construction has attracted consideration. Laser-induced periodic floor constructions (LIPSS) makes use of the interference between incident gentle and floor electromagnetic waves to etch the fabric, so it has excessive processing accuracy. Furthermore, in contrast with the normal laser interference processing methodology, the self-organized processing methodology makes its experimental setup easy and scanning with a big gentle spot makes its fabrication velocity quickly excessive.

Researchers led by Prof. Min Qiu at Westlake College, China have intensive analysis expertise in LIPSS. They not too long ago found that when a periodic grating is induced on the floor of a skinny a-Si movie, the interval of the grating is affected by the interference of incident gentle with completely different origins of electromagnetic waves. Their paper, “Influence of movie thickness in laser-induced periodic constructions on amorphous Si movies” has been printed in Frontiers of Optoelectronics.

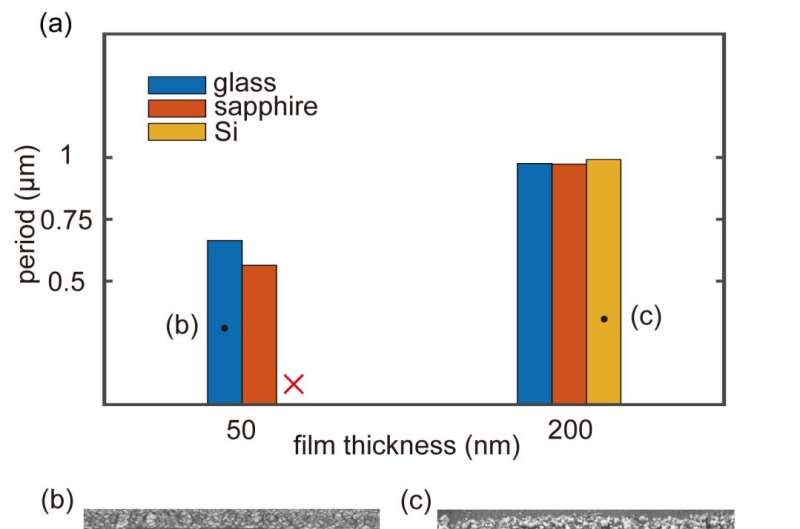

When the thickness of the amorphous silicon movie is small (50 nm) and the substrate is a non-silicon materials, LIPSS with a small interval is induced below the dominance of the slab waveguide mode. On this case, when the substrate materials modifications (refractive index modifications), the interval of the LIPSS additionally modifications. When the thickness of the amorphous silicon movie is massive (200 nm), the incident gentle interferes with the quasi-cylindrical wave, and induces the expansion of LIPSS below the joint motion of near-field and far-field. The interval of LIPSS on this mode is barely smaller than the laser wavelength and is unbiased of the substrate materials. Finite-difference time-domain method-based numerical simulations help the experimental discoveries.

Extra data:

Liye Xu et al, Influence of movie thickness in laser-induced periodic constructions on amorphous Si movies, Frontiers of Optoelectronics (2023). DOI: 10.1007/s12200-023-00071-6

Supplied by

Frontiers Journals

Quotation:

Influence of movie thickness in laser-induced periodic constructions on amorphous Si movies (2023, July 5)

retrieved 8 July 2023

from https://phys.org/information/2023-07-impact-thickness-laser-induced-periodic-amorphous.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.