Synthetic Intelligence is presently one of many foremost buzzwords within the tech world, with the additive manufacturing business growing its justifiable share of AI hype over latest months. Earlier this 12 months, the 3D Printing Trade Govt Survey highlighted automated AI 3D mannequin era as being key to the way forward for 3D printing.

Considerably forward of this present AI increase was 3D printing software program developer Ai Construct. Since 2015, the London-based firm has labored to develop AI pushed toolpath era and automatic high quality assurance software program for additive manufacturing.

3D Printing Trade just lately sat down with Ai Construct CEO Daghan Cam, and Industrial Director Luke Rogers, to be taught extra concerning the firm’s software program choices, and the way developments in AI are impacting industrial large-format 3D printing.

Ai Construct’s mission to extend AM accessibility

Ai Construct was based by Daghan Cam and firm COO Michael Michail Desyllas. Coming from an architectural background, Cam and Desyllas launched the corporate with the purpose of simplifying large-format 3D printing.

“We have been actually excited by the additive manufacturing expertise, and we noticed that as the way forward for making issues,” defined Cam. Nevertheless, Cam and Desyllas quickly “began to comprehend that 3D printing expertise may be very error susceptible, particularly on the subject of bigger codecs.”

In the end, Cam factors to the “dependency on skilled machine operators to show designs into bodily elements” as stunting the event and widespread adoption of 3D printing. “We expect that if we are able to make the expertise extra accessible, that’s going to unlock progress a lot sooner.”

“We try to make it tremendous straightforward for anybody. Even a designer that doesn’t have a lot 3D printing background ought to be capable of ship their designs into machines,” added Cam. “Whenever you have a look at the total lifecycle, the prices rapidly add up. So we try to make that course of much more environment friendly by automating duties. And that’s the place AI actually is available in.”

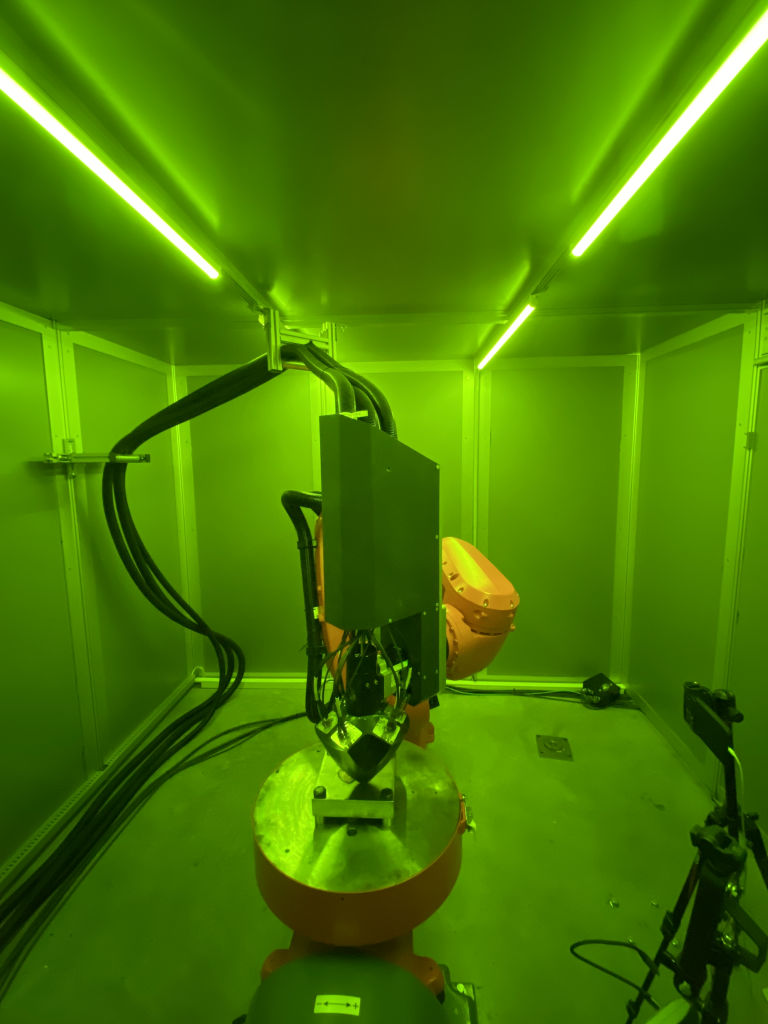

Ai Construct has already partnered with a lot of main 3D printer {hardware} producers, together with Hans Weber Maschinenfabrik, Meltio, KUKA, Evo3D, CEAD, and Huge Dimension. Via these partnerships, the corporate incorporates a variety of large-format 3D printers into their Ai Lab workshop. Right here, the {hardware} is used to check, develop, confirm, and combine Ai Construct’s software program for a rising vary of functions.

As an illustration, via their relationship with metallic 3D printer producer Meltio, Ai Construct tailored their nonplanar slicing and multi-axis toolpath optimization performance for Direct Vitality Deposition (DED) metallic 3D printing. “Following Meltio, we now have many several types of metallic 3D printing built-in into the product. It was thrilling as a result of it all of the sudden unlocked a really large market alternative for us,” commented Cam.

What are your ideas on being based mostly in London?

Cam was eager to level out the advantages of being based mostly in London, highlighting the sturdy expertise pool within the UK’s capital.

“There’s a robust engineering ecosystem, particularly on the software program facet,” claimed Cam, who pointed to the broad vary of AI software program corporations within the monetary tech and well being tech areas. “It’s a really vibrant ecosystem, on the subject of software program, AI, and digital applied sciences, and we’re very pleased to be a part of that,” added Cam. “It couldn’t be the identical if we have been situated elsewhere within the UK, however London is actually the hub of software program applied sciences and deep tech.”

Nevertheless, Rogers highlighted that, while based mostly in London, Ai Construct is known as a world group. “We’ve bought so many various individuals who work for us. I feel, final time we counted, we had about 16 completely different nationalities, from about 30 Completely different individuals who work within the enterprise. So solely a few third of the corporate is definitely current within the UK.”

Ai Construct’s software program

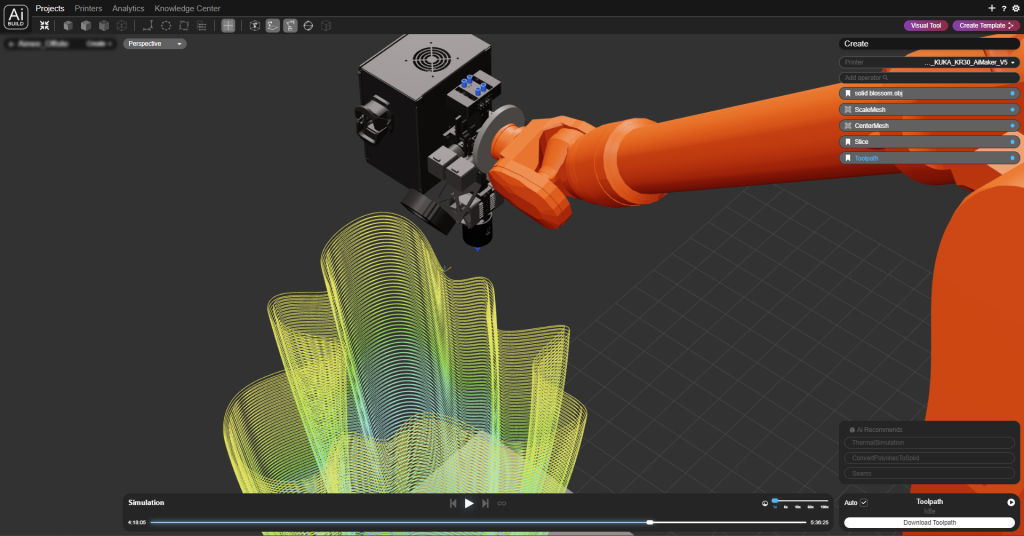

Ai Construct’s key product is its AiSync software program, an AI-driven toolpath optimization and high quality management platform.

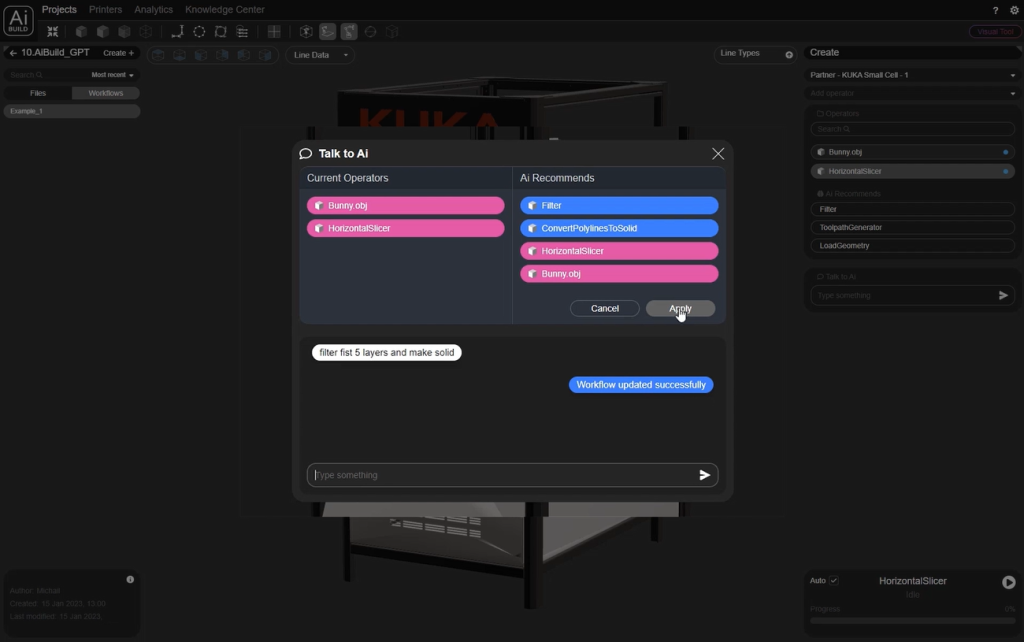

Concerning toolpath optimization, it was introduced earlier this 12 months that Ai Construct had developed a course of which permits customers to create superior 3D printing toolpaths utilizing pure language prompts. This characteristic, known as Speak to AiSync, permits customers to enter easy textual content, comparable to “slice the half with 2mm layer peak.” This textual content is then translated into machine directions to provide the specified 3D printed half.

Key to this characteristic is giant language AI fashions. AiSync makes use of OpenAI on the again finish, with GPT-4 operating the software program’s pure language processing. “With the addition of enormous language fashions, we’re in a position to translate easy English phrases, plain sentences, right into a stack of workflow that we create on our software program,” defined Cam. “The objective is to make it tremendous accessible to inexperienced customers by making the person expertise actually clean.”

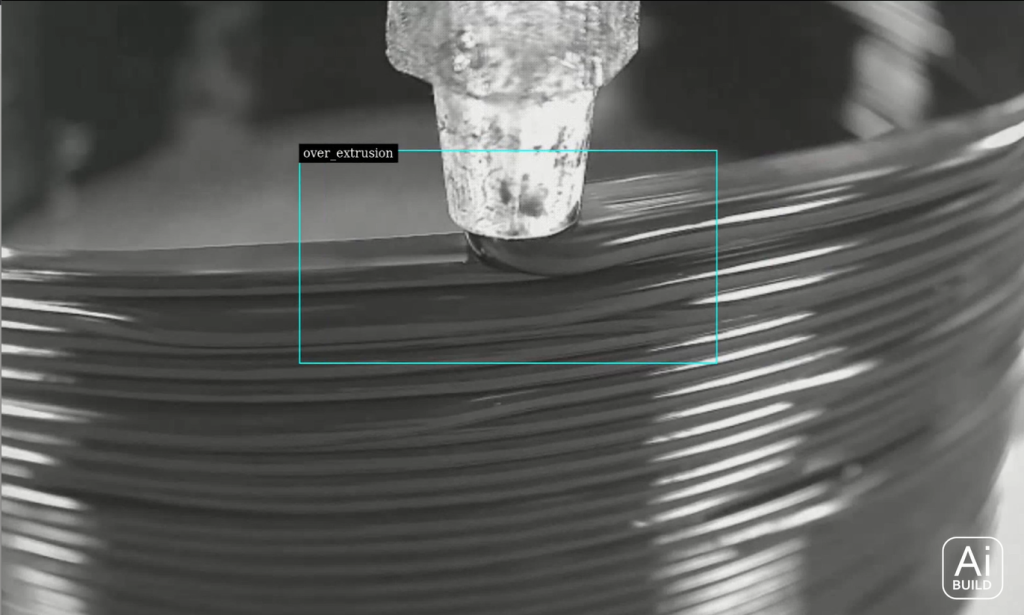

As soon as the toolpath has been despatched to the 3D printer, AiSync gives machine-learning-driven high quality management. Rogers said that, inside large-format 3D printing, there’s usually solely a 40% success price when first 3D printing an element. Based on Rogers, “utilizing machine studying, and mixing that again into the preliminary toolpath, you possibly can simply stand up into the 90% plus first-time print success price.”

AiSync information your entire 3D printing course of, routinely detecting any anomalies that weren’t deliberate throughout the simulation part. Cam factors to aerospace as a key vertical benefitting from this characteristic, particularly throughout the manufacturing of elements that require certification and high quality assurance. “They must do tons and plenty of testing after manufacturing. We’re minimizing that want for non-destructive testing and several types of {qualifications}.”

Past aerospace, Cam highlighted automotive, power, marine, and development as the important thing vertices this software program is aimed in the direction of. “I might say possibly 80 or 90% of our clients are falling into considered one of these 5 classes,” claimed Cam. While Cam couldn’t disclose too many names, world engineering options agency Weir Group and aerospace producer Boeing have been pinpointed as key clients

using AiSync software program.

AiSync cloud connectivity

AiSync can be cloud-based, one thing which is alleged to distinguish AI Construct from the competitors. “So far as I’m conscious, we’re the one firm that has a cloud platform that’s pushed by way of knowledge and collaboration, and the usage of AI,” claims Cam. Rogers echoed this sentiment, including that “There’s nobody doing precisely what we’re doing.”

“We’re enabling the free stream of data, and that results in a lot sooner innovation and shorter product life cycles,” based on Cam. “It’s all about accessibility and comfort for the customers. You don’t want to put in something, so that you could be in your cell phone or iPad and subsequent to the machine.”

Along with distant 3D print monitoring and management capabilities, this cloud connectivity additionally permits knowledge to be transferred and exams carried out “between geographies.” Cam pointed to 1 instance whereby toolpaths have been created within the firm’s London-based Ai Lab. These directions have been then despatched to a 3D printer in Germany, the place the elements have been 3D printed with none further human enter.

Key benefits of utilizing AI inside additive manufacturing

What are the important thing advantages of incorporating AI expertise into additive manufacturing? Cam pointed to scaling, with AI being “essential” to attaining full automation, “which we expect is required to scale the expertise.”

“If the method isn’t automated, it’s error susceptible as a result of it’s depending on the standard of your additive engineers information, and the information switch is extraordinarily tough,” commented Cam. “Our objective is to completely automate the method, and AI turns into actually important in the direction of the top of that final mile of automation.”

While Ai Sync doesn’t presently provide full automation, however is somewhat a collaborative course of between person and software program, Cam asserted that “the place we’re going is unquestionably increased and better ranges of automation.”

“As we get there, the method is turning into rather more environment friendly. Much less errors, much less price. Many new functions get unlocked as the fee is getting decrease by automating the method.”

So what are the time and price financial savings supplied by AI? Based on Cam, “It’s very utility particular.”

On the subject of tooling functions, the most important advantage of AI is slicing the prototyping part. Cam claims that, presently, engineers are having to make a finest guess on the slicing software program and toolpath era, bodily 3D printing the half to view the outcomes.

“So it often takes two to 3 makes an attempt till they get it proper the primary time. It’s often just a few weeks earlier than the manufacturing really begins from the design part. And within the worst case, they could want to return to design and iterate on the design as effectively,” said Cam. Due to this fact, AI modeling and simulation makes a big influence on this stage of improvement, “eliminating the prototyping part earlier than the precise manufacturing begins.”

With reference to high-volume manufacturing, AI is alleged to primarily profit high quality assurance. “It’s actually essential for patrons to have belief within the expertise,” claims Cam. That is the place AiSync is available in. “We’re taking that high quality assurance and placing it inside the method […] As you print the elements you’ve got a stay report and the post-print stories that give full confidence to the client.”

The way forward for AI and additive manufacturing

Wanting ahead, Cam sees a vivid future for AI and 3D printing, viewing “AI as a really sturdy companion to engineers and designers.” Key to this relationship is alleged to be communication.

“The position of AI shifting ahead is going to be round making the communication between the computer systems, the methods and the people much more fluid. So fluid that it’ll really feel like there isn’t a laptop, you’re simply speaking to a colleague and the machine understands what you imply,” commented Cam.

Rogers echoed this sentiment, stating that “sooner or later, you received’t want technical competence to have the ability to run machines.” The long-term objective of AiSync is to additional simplify the additive manufacturing course of, “to make it accessible, to cut back that barrier of entry, to permit the elements to be produced at the next high quality, sooner and extra precisely than any human thoughts can do.”

Subscribe to the 3D Printing Trade publication to maintain updated with the newest 3D printing information. It’s also possible to comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of accessible roles and kickstart your profession.

Featured picture exhibits Ai Construct CEO Daghan Cam at Ai Construct’s Ai Lab. Picture by 3D Printing Trade.