I visited the London workplace of Luke Smoothy, founding father of Get It Made, an organization specializing in superior manufacturing methods, together with CNC machining and 3D printing.

Smoothy’s journey started with a childhood fascination for the “enterprise of creating issues.” Designing workplace furnishings and spending numerous hours on CAD in his early days, he was drawn into the nuances of product creation. Regardless of a love for the design and prototyping processes, he highlighted a problem, “Simply how exhausting it was to take care of numerous producers.”

It’s a well-known tune within the manufacturing world, the place service suppliers typically neglect that they’re, firstly, in a service enterprise. Smoothy recollects when immediate replies and common suggestions have been luxuries, not the norm. However amidst these challenges, he discovered just a few responsive factories – notably one in China. These institutions breathed a contemporary perspective into his manufacturing experiences, setting the stage for Get It Made.

Began as a “facet hustle,” Smoothy’s firm responded to a spot he noticed available in the market. Whereas rivals, fuelled by large enterprise capital investments, raced to take away the human ingredient, Get It Made consciously selected the alternative path. Smoothy elaborates: “Quite a lot of our shoppers come to us for this human interplay… they’re gonna need to know, ‘how’s the challenge going?’ fairly than simply add their CAD information and take a look at.” It’s a novel pitch in a world shifting more and more towards automation.

But, there’s no denying the affect of know-how on manufacturing. The dialog shifts to 3D printing, which Smoothy admits he was initially “a bit antsy” about. He noticed it as a commoditized service, with normal machines and supplies leaving little room so as to add distinctive worth. Nonetheless, his stance has developed with the occasions.

Make your nominations for the 3D Printing Business Awards now.

Tech Metropolis: London as a 3D printing hub?

London, as a 3D printing hub, appears an attention-grabbing alternative. Many would possibly level to Munich or Hamburg as Germany’s 3D printing powerhouses, but the British capital has its personal hidden group of digital creators. “There are literally a number of folks like us in London. 3D Print UK, 3D Folks, and others,” Smoothy famous. Whereas establishing in London was initially a choice of comfort – “I’ve all the time lived right here,” he stated – town’s potential as a 3D printing middle is plain. London’s draw stays its magnetism for expertise. The vibrancy and variety of town guarantee a gradual inflow of experience.

Nonetheless, London’s status as a digital powerhouse leans closely in the direction of software program fairly than {hardware}. The London Tech Week, for instance, stays biased in favor of digital companies, prompting questions on whether or not town is doing sufficient to foster its {hardware} and manufacturing expertise.

The problem for London, nevertheless, is a basic one: area. “Area is dear,” Smoothy lamented. When manufacturing must escalate past digital design and embody processes like CNC machining, discovering the best premises turns into a problem.

Constructing a enterprise

Discussing ‘manufacturing as a service,’ Smoothy elucidated the enterprise mannequin as a “one-stop resolution.” The goal is simplicity. A focus for this service mannequin is an enhanced buyer expertise. From sourcing uncooked supplies to advanced assemblies, firms like Get It Made goal to ease your complete course of. Smoothy added, emphasizing his imaginative and prescient, “Should you want one thing made, you simply come to us.”

Recruitment, although, is the hardest nut to crack. “It’s undoubtedly the toughest a part of my job,” Smoothy admitted. The problem? Discovering people with a mix of technical know-how and buyer relations experience.

Exploring newer horizons, Smoothy reveals their enterprise into the HP Jet Fusion 3D printers. This know-how guarantees a twin benefit: a aggressive edge and potential price financial savings.

Nonetheless, the pivot in the direction of 3D printing isn’t merely about leveraging new know-how. Smoothy sees it as a possible “gateway drug” to attract clients into their extra profitable companies, noting that “3D printing is a a lot larger market.” The mixing of 3D printing is envisioned to complement their present manufacturing operations, making their enterprise mannequin much more sturdy.

The Battle of Platforms: Consistency vs Scale

Turning the dialog in the direction of on-line platforms, Smoothy highlights some underlying issues. There’s a point out of inconsistencies, with costs generally doubling after an preliminary quote and a scarcity of assured high quality when scaling orders. This unpredictability is the place Get It Made sees its energy — within the supply of constant high quality.

This consistency is hard-earned. Smoothy explains their deepening relationship with a major manufacturing unit in China, which has enabled the creation of “information” and “consistency” over time. Whereas manufacturing is fraught with challenges, the capability to handle these issues head-on and discover options has been a trademark of their success.

This basis has led to collaborations with massive names like Ocado, Brompton, Airbus, and Stanley. Though lots of their tasks are confidential, Smoothy hints at their engagement with area of interest segments corresponding to satellite tv for pc elements – maybe even of the CubeSat dimension.

This breadth extends past area to even the streets of London. One such enterprise concerned creating aluminum extrusions for a budding electrical scooter—a novel problem in a market the place most producers demand large portions. Smoothy recounted, “Most producers within the UK don’t [produce small quantities]. They need two tonnes of aluminum, which might imply an extrusion that might be like a kilometer.”

On the coronary heart of Get It Made’s ethos lies a dedication to supporting innovation at its grassroots. They’ve seen a rising pattern of shortened product life and design cycles, with elevated demand for novelty. This leads them to work with inventors, offering steering when obligatory. One intriguing challenge revolved round an attachment for a WD-40 can to wash bicycle chains – a distinct segment but modern resolution within the biking world.

Their dedication to the broader group doesn’t cease with product design. They’ve initiated grants for budding entrepreneurs with a give attention to creating affect. A notable occasion of this initiative is their assist throughout Worldwide Girls in Engineering Day. “We selected an organization led by a feminine founder. It’s a sensible menstrual system that gives well being info,” Smoothy defined. The grant, which ranged as much as £10,000, facilitated prototyping and iterative designs for such groundbreaking merchandise.

One other instance is ManholeMetrics, an ingenious system that, as absurd because it sounds, alerts households to imminent sewage backup. Whereas at first look, it is likely to be dismissed as a novelty, Smoothy identified the real practicality and market demand for such an answer. Diversifying past IoT, Smoothy touched upon their involvement with diverse improvements, from fireplace detection techniques monitoring massive forested areas from a single level to extra area of interest ventures like Flux Aviation’s exploration into semi-electric propulsion. Each challenge underscores Get It Made’s knack for figuring out, nurturing, and scaling modern concepts. And it’s not all high-tech: think about their collaboration with an organization innovating in fish farming, with a digital camera system that screens fish well being in real-time.

“We mould up tasks for them. Low quantity injection molding as a result of they’re by no means going to want lots”, Smoothy defined, alluding to the bespoke nature of their tasks.

However scaling in a world dominated by giants brings its challenges. Being a smaller participant, Get It Made has needed to navigate the minefield of perceptions, aiming to challenge themselves as accessible and aggressive. “We don’t need to seem an excessive amount of like we’re only a very small, boutique type of factor; we now have the potential,” remarked Smoothy. This technique appears to work, as they repeatedly discover themselves shoulder-to-shoulder with trade behemoths.

Manufacturing as a service

The dialog naturally steered in the direction of the way forward for manufacturing as a service. Surprisingly, Smoothy foresees a shift again to in-house manufacturing for a lot of firms. Exterior platforms can typically result in high quality inconsistencies, and native machine outlets are rising cautious of being beholden to bigger gamers.

Mentioning an organization referred to as Paperless Components, Smoothy highlighted their game-changing strategy. As an alternative of forcing automation, they goal to expedite the quoting course of. A seemingly minor nuance, however one that may shake up the trade. This software-as-a-service resolution for manufacturing may be the device to stage the taking part in subject.

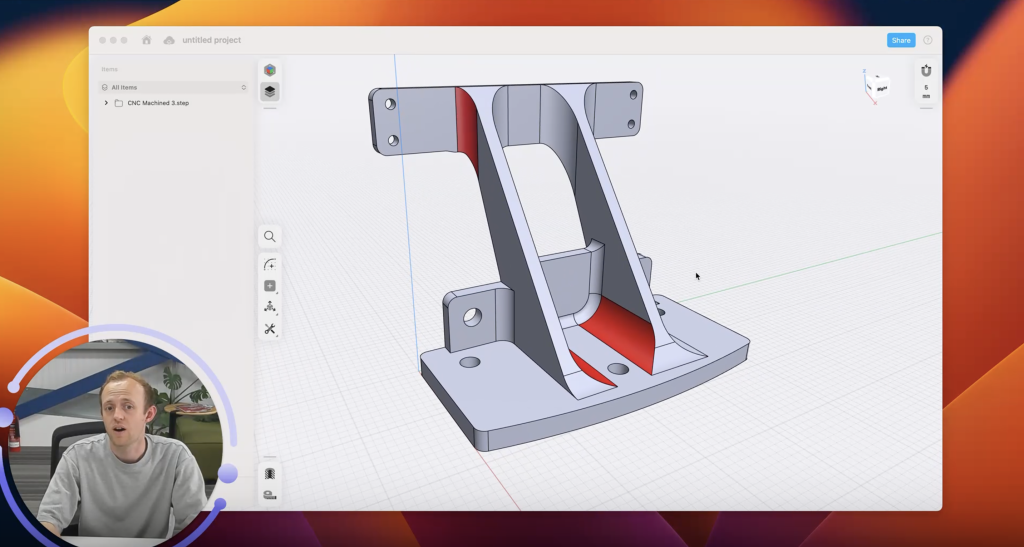

“There’s an ease to additive manufacturing, a type of straightforwardness when it comes to dimension and quantity issues,” Smoothy started, highlighting the distinction to the intricate choices wanted in CNC machining. But, he rapidly identified the immense variables within the latter: “What’s in your device room, what cutters, what fixtures, what’s the envelope for machining? So many variables.”

Get It Made integrates a digital strategy to the standard manufacturing course of. “It’s like a digital Napster for manufacturing,” he quipped. Purchasers can add CAD information, obtain quotes, and handle their orders. But, amidst this automation, the human contact is pivotal. The group at Get It Made meticulously evaluations every challenge, making certain points are caught early. As Smoothy candidly famous, “Generally, laptop says no. However with human ingenuity, you’ll be able to resolve the challenges.”

However what in regards to the trade’s broader shifts and the traits shaping the 3D printing panorama? For Smoothy, it’s about marrying additive and subtractive processes. Many producers keep away from combining these strategies, however Get It Made welcomes it. “We are able to 3D print in metallic after which machine it afterward. This cross-pollination, I imagine, could possibly be a burgeoning pattern,” Smoothy recommended.

In a world of automated manufacturing, the dialog serves as a reminder: innovation lies on the intersection of know-how and human ingenuity. It’s not nearly 3D printing the longer term—it’s about crafting it.

Subscribe to the 3D Printing Business publication to maintain updated with the newest 3D printing information. It’s also possible to comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a choice of accessible roles and kickstart your profession.

Featured picture exhibits Luke Smoothy, Get It Made Director. Photograph through Get It Made.