3D printing has opened up a world of prospects, however relating to printing with clay, there are challenges abound. Enter maker David Sfier, who has developed an up to date extruder designed to work with an Ender 3 printer, making clay 3D printing extra accessible and sensible.

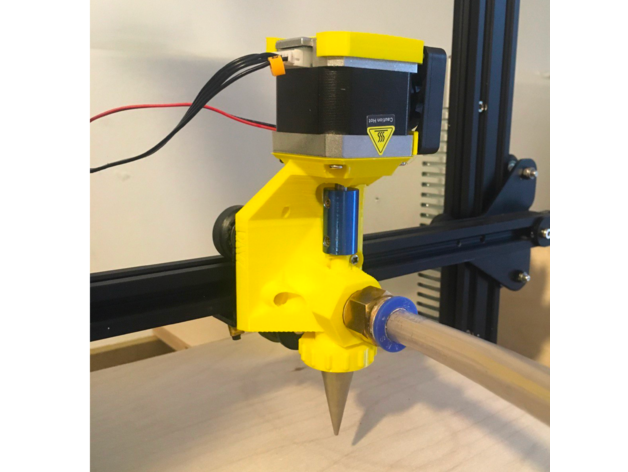

What units this tradition extruder aside is its capability to deal with clay, a fabric that defies conventional spool-based storage. As a substitute, a transparent tube feeds frivolously pressurized clay into the extruder. As air escapes from the highest, an auger effectively homogenizes the clay and propels it by means of the nozzle.

The extruder’s ingenious design tackles the problem of air bubbles (a standard drawback in clay printing) by permitting air to vent by means of a slim hole on the high, the extruder ensures clean clay circulate downward.

Sfier drew inspiration from clay-printing pioneers like Piotr Waśniowski and his de-airing clay extruder, together with Jonathan Maintain, whose complete documentation on 3D printing with clay is available.

The range of challenges in clay printing invitations continuous innovation, with unconventional strategies like utilizing a subwoofer beneath a print mattress resulting in distinctive patterns.

You possibly can study extra concerning the mission, and obtain the mission information over at this hyperlink.

Supply: hackaday.com

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to join our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.