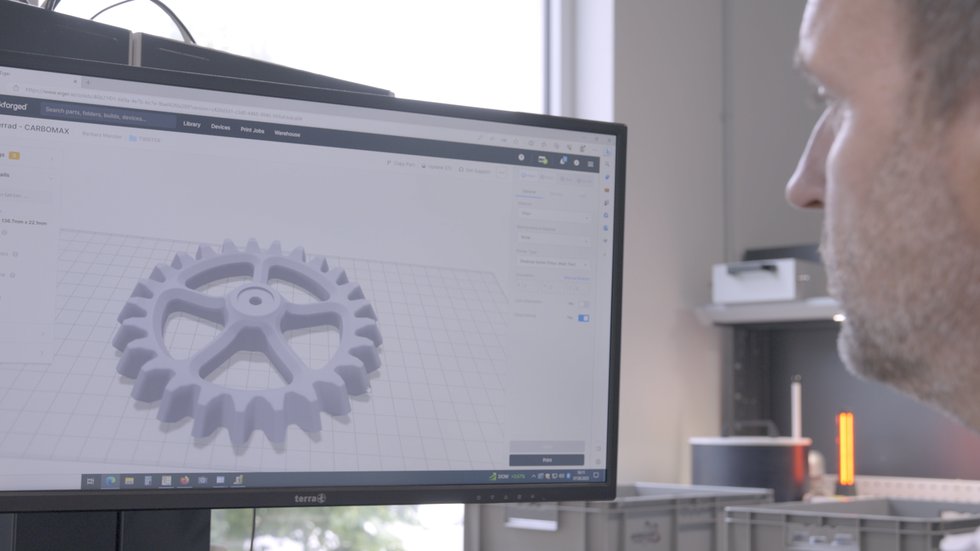

Markforged has introduced the launch of its Digital Supply on-demand elements platform, which allows the licensing and additive manufacturing of manufacturer-certified elements on the level of want.

As soon as digital half designs are uploaded, customers of Digital Supply – whether or not they be prospects, distributors or contract producers – can license the best to print elements onsite or via a community of accredited print service suppliers.

Markforged says it has designed this platform to ‘supply constant, dependable, turnkey manufacturing’ for 3D printed elements, whereas ‘delivering the promise’ of digital warehousing with end-to-end course of management. When importing half designs, distributors can specify and lock printing course of necessities, with sturdy safety safeguarding the information and encrypted print directions being despatched on to printers to guard designs.

By way of Digital Supply, each distributors and prospects are mentioned to have the ability to profit from lowered stock prices and less complicated substitute half operations, which Markforged believes will end in elevated productiveness, profitability, and buyer satisfaction.

“Digital Supply unlocks a brand new approach of managing provide chains,” commented Markforged CEO Shai Terem. Every single day a producing line is down attributable to damaged or worn elements can price hundreds of thousands of {dollars} in misplaced productiveness. Availability of spare elements is essential to producers’ success – however retaining an in depth bodily stock ties up capital in elements that will go untouched for years. Digital Supply not solely can simplify logistics however may construct resiliency into the provision chain and enhance profitability on account of these efficiencies. With Digital Supply, elements may be digitised and printed on the time and level of want with out the must be manufactured upfront, shipped and saved till wanted.”

Already, sand blasting machine producer BMF GmbH has change into a vendor on Digital Supply, whereas Automation Alley has dedicated to utilizing Digital Supply for its Venture DIAMOnD initiative. BMF has put in greater than 200 of its machines worldwide, every geared up with 60 printed elements, which want changing each three to 4 months when the machines are operating at full capability. Venture DIAMOnD, in the meantime, is the world’s largest emergency response community for on-demand printing, with small and medium-sized producers working 300 Markforged printers.

“We wanted a big quantity of storage capability to have the ability to inventory all of the spare elements, and infrequently, the prolonged supply time is linked to the client’s ordering course of, as the executive procedures often take too lengthy, when BMF ships the spare elements on the identical day,” provided Ronny Bernstein, CEO of BMG GmbH, “Through Digital Supply, the part may be printed on-site the second a failure or put on is detected.”

“We worth Markforged due to its robust emphasis on defending the digital recipe of elements and imposing the requirements of high quality for remotely printed elements.” Added Pavan Muzumdar, Chief Working Officer of Automation Alley and CEO of Venture DIAMOnD. “We imagine the way forward for manufacturing is distributed manufacturing. By connecting our bodily world via safe digital inventories, Digital Supply may be very strongly aligned with our imaginative and prescient for the longer term.”