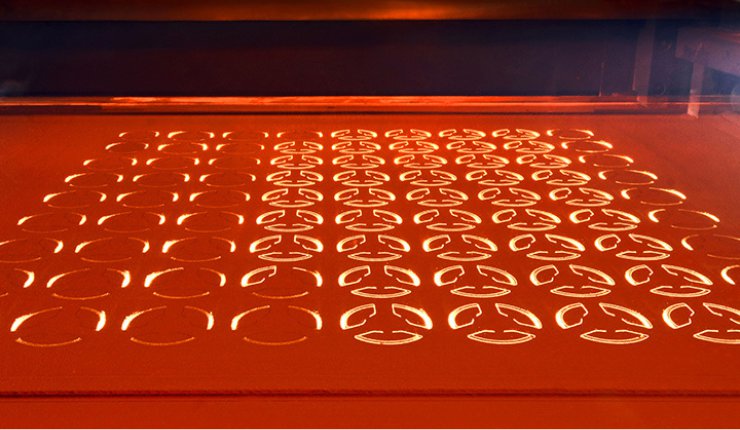

Mechnano has introduced that its PK ESD laser sintering powder has been permitted on Farsoon’s 252P Collection and Flight 403P Collection machines. The PK ESD powder combines Jabil’s PK 5000 engineered powder with a coating formulation utilizing Mechnano’s expertise, D’Func (Discrete, Dispersed, and Functionalised Carbon Nanotubes).

The D’Func-based coating introduces nano-uniform electrostatic dissipative properties to Laser Sintered elements. Mechnano says that PK ESD retains the distinctive benefits of PK 5000, eco-friendly elements with excessive affect power, chemical, and abrasion resistance, and improved elongation over general-purpose nylons, to resist useful testing and manufacturing use.

Mechnano says that due to D’Func, PK ESD elements have Nano-Uniform ESD at 107 ohms floor resistivity, unbiased of the construct orientation and powder refresh charge, whereas retaining PK 5000’s mechanical efficiency.

The elements additionally allow enhancements in response to the corporate, together with a 25% improve in affect resistance to 103.6 J/m; 20% improve in elongation at break to 44%; and no break flexural specimens inside 5% pressure restrict of ASTM D790 Process A & B exams.

“PK ESD’s nano uniformity is the reply to various ESD powder and filament options with unpredictable ESD efficiency,” stated Mechnano President Bryce Keeler. “With Farsoon, we’re enabling the AM market by eliminating costly and time-consuming necessities to check and validate static-dissipative efficiency for every half. And the actual fact we’re doing this with a high-performance and eco-friendly materials makes it much more compelling.”

Don Xu, Managing Director of Farsoon Americas Corp stated: “We’re excited to work with Mechnano’s revolutionary D’Func coating. Utilized to supplies reminiscent of PK 5000, this coating and powder mixture has the potential to open up new avenues of additive manufacturing functions.”

Mechnano says that PK ESD on Farsoon machines can create “correct, excessive efficiency elements”, and is a quick-turn answer for end-use functions reminiscent of drones, gasoline programs, and sturdy ESD tooling, due to its excessive affect resistance, gasoline resistance, static-dissipative properties, and excessive elongation at break.

Learn extra:

Farsoon Applied sciences breaks floor on new R&D headquarters for industrial 3D printing

Mechnano releases and validates polycarbonate ESD on ARBURG 3D printers