This submit was co-authored by Dan Russ, Affiliate Director, and Sacha Abinader, Managing Director from Accenture.

The 12 months 2022 was a notable one within the historical past of our local weather—it stood because the fifth warmest 12 months ever recorded1. A rise in excessive climate circumstances, from devastating droughts and wildfires to relentless floods and warmth waves, made their presence felt greater than ever earlier than—and 2023 appears poised to shatter nonetheless extra information. These unnerving circumstances display the ever-growing affect of local weather change that we’ve come to expertise because the planet continues to heat.

Microsoft’s sustainability journey

At Microsoft, our method to mitigating the local weather disaster is rooted in each addressing the sustainability of our personal operations and in empowering our clients and companions of their journey to net-zero emissions. In 2020, Microsoft set out with a strong dedication: to be a carbon-negative, water optimistic, and zero-waste firm, whereas defending ecosystems, all by the 12 months 2030. Three years later, Microsoft stays steadfast in its resolve. As a part of these efforts, Microsoft has launched Microsoft Cloud for Sustainability, a complete suite of enterprise-grade sustainability administration instruments aimed toward supporting companies of their transition to net-zero.

Furthermore, our contribution to a number of world sustainability initiatives has the aim of benefiting each particular person and group on this planet. Microsoft has accelerated the supply of revolutionary local weather applied sciences by means of our Local weather Innovation Fund and is working laborious to strengthen our local weather coverage agenda. Microsoft’s give attention to sustainability-related efforts kinds the backdrop for the subject tackled on this weblog submit: our partnership with Accenture on the applying of AI applied sciences towards fixing the difficult drawback of methane emissions detection, quantification, and remediation within the power business.

“We’re excited to accomplice with Accenture to ship methane emissions administration capabilities. This combines Accenture’s deep area data along with Microsoft’s cloud platform and experience in constructing AI options for business issues. The result’s an answer that solves actual enterprise issues and that additionally makes a optimistic local weather affect.”—Matt Kerner, CVP Microsoft Cloud for Trade, Microsoft.

Why is methane necessary?

Methane is roughly 85 occasions stronger than carbon dioxide (CO2) at trapping warmth within the ambiance over a 20-year interval. It’s the second most ample anthropogenic greenhouse fuel after CO2, accounting for about 20 % of world emissions.

The worldwide oil and fuel business is without doubt one of the major sources of methane emissions. These emissions happen throughout your complete oil and fuel worth chain, from manufacturing and processing to transmission, storage, and distribution. The Worldwide Power Company (IEA) estimates that it’s technically potential to keep away from round 75 % of right now’s methane emissions from world oil and fuel operations. These statistics drive house the significance of addressing this vital situation.

Microsoft’s funding in Challenge Astra

Microsoft has signed on to the Challenge Astra initiative—along with main power corporations, public sector organizations, and educational establishments—in a coordinated effort to display a novel method to detecting and measuring methane emissions from oil and fuel manufacturing websites.

Challenge Astra entails an revolutionary sensor community that harnesses advances in methane-sensing applied sciences, information sharing, and information analytics to supply near-continuous emissions monitoring of methane throughout oil and fuel services. As soon as operational, this type of good digital community would permit producers and regulators to pinpoint methane releases for well timed remediation.

Accenture and Microsoft—The way forward for methane administration

Attaining the aim of net-zero methane emissions is changing into more and more potential. The applied sciences wanted to mitigate emissions are maturing quickly, and digital platforms are being developed to combine advanced elements. As referenced in Accenture’s latest methane thought management piece, “Greater than sizzling air with methane emissions”. What is required now’s a shift—from a reactive paradigm to a preventative one—the place the vital situation of leak detection and remediation is reworked into leak prevention by leveraging superior applied sciences.

Accenture’s particular capabilities and toolkit

So far, the power business’s method to methane administration has been fragmented and comprised of a bunch of pricey monitoring instruments and tools which were siloed throughout varied operational entities. These siloed options have made it tough for power corporations to precisely analyze emissions information, at scale, and remediate these issues shortly.

What has been missing is a single, reasonably priced platform that may combine these elements into an efficient methane emissions mitigation instrument. These elements embrace enhanced detection and measurement capabilities, machine studying for higher decision-making, and modified working procedures and tools that make “net-zero methane” occur quicker. These platforms are being developed now and might accommodate all kinds of know-how options that can kind the digital core crucial to realize a aggressive benefit.

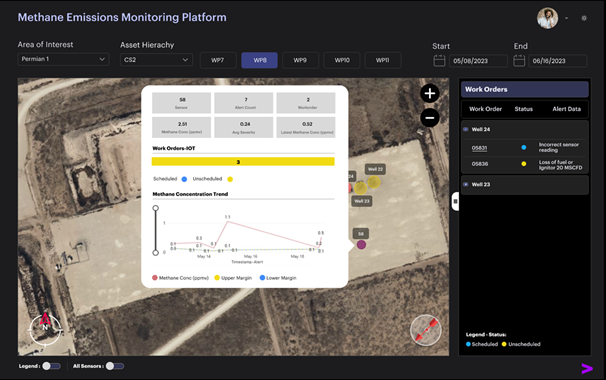

Accenture has created a Methane Emissions Monitoring Platform (MEMP) that facilitates the mixing of a number of information streams and embeds key methane insights into enterprise operations to drive motion (see Determine 1 beneath).

Determine 1: Accenture’s Methane Emissions Monitoring Platform (MEMP).

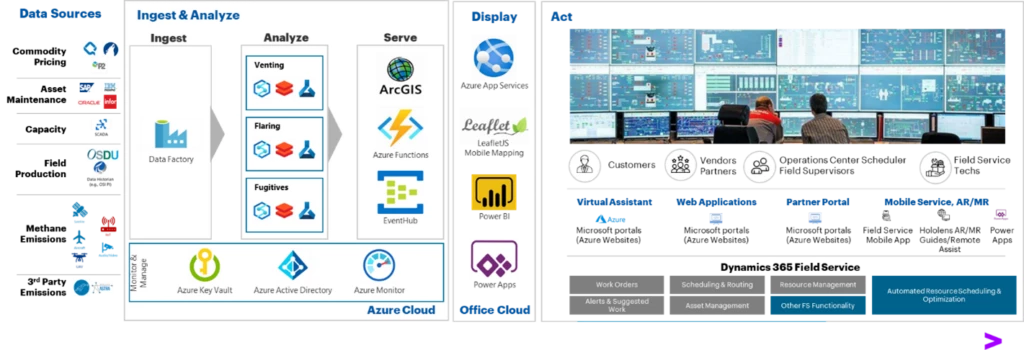

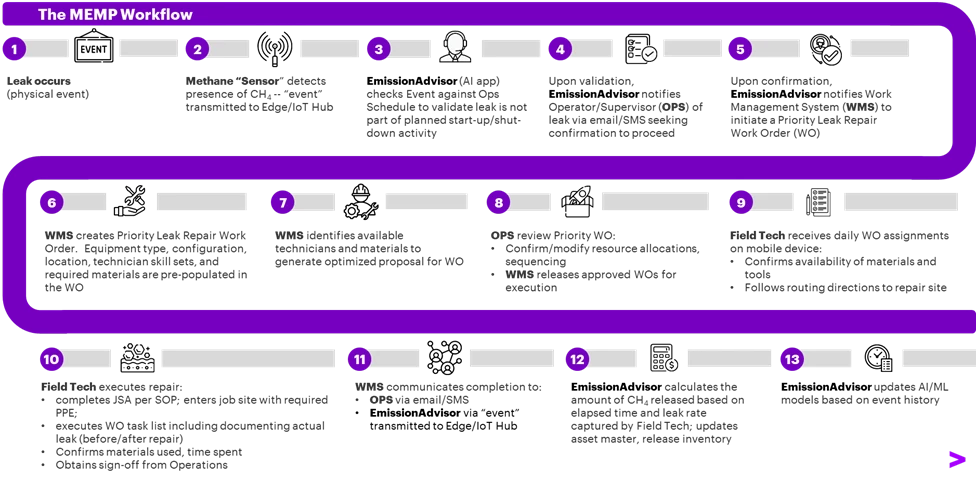

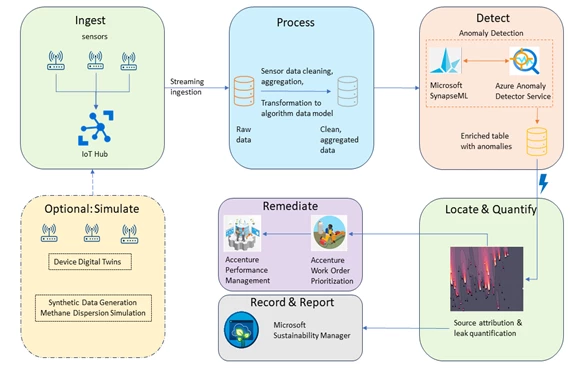

The cloud-based platform, which runs on Microsoft Azure, permits power corporations to each measure baseline methane emissions in close to real-time and detect leaks utilizing satellites, mounted wing plane, and floor stage sensing applied sciences. It’s designed to combine a number of information sources to optimize venting, flaring, and fugitive emissions. Determine 2 beneath illustrates the aspirational end-to-end course of incorporating Microsoft applied sciences. MEMP additionally facilitates connectivity with back-end programs answerable for work order creation and administration, together with the scheduling and dispatching of discipline crews to remediate particular emission occasions.

Determine 2: The Methane Emissions Monitoring Platform Workflow (aspirational).

Microsoft’s AI instruments powering Accenture’s Methane Emissions Monitoring Platform

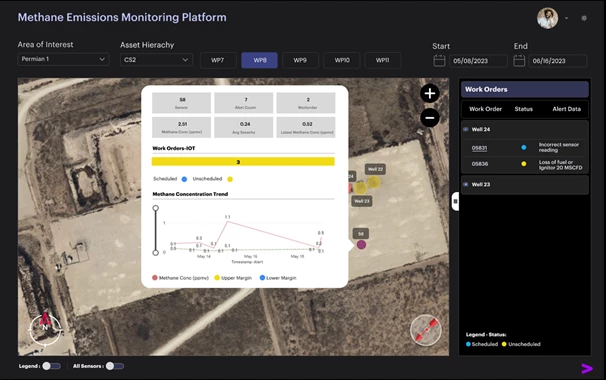

Microsoft has offered quite a lot of Azure-based AI instruments for tackling methane emissions, together with instruments that assist sensor placement optimization, digital twin for methane Web of Issues (IoT) sensors, anomaly (leak) detection, and emission supply attribution and quantification. These instruments, when built-in with Accenture’s MEMP, permit customers to observe alerts in close to real-time by means of a user-friendly interface, as proven in Determine 3.

Determine 3: MEMP Touchdown Web page visualizing wells, IoT sensors, and Work Orders.

“Microsoft has developed differentiated AI capabilities for methane leak detection and remediation, and is happy to accomplice with Accenture in integrating these options onto their Methane Emissions Monitoring Platform, to ship worth to power corporations by empowering them of their path to net-zero emissions”—Merav Davidson, VP, Trade AI, Microsoft.

Methane IoT sensor placement optimization

Putting sensors in strategic places to make sure most potential protection of the sector and well timed detection of methane leaks is step one in direction of constructing a dependable end-to-end IoT-based detection and quantification answer. Microsoft’s answer for sensor placement makes use of geospatial, meteorological, and historic leak price information and an atmospheric dispersion mannequin to mannequin methane plumes from sources inside the space of curiosity and procure a consolidated view of emissions. It then selects the very best places for sensors utilizing both a mathematical programming optimization methodology, a grasping approximation methodology, or an empirical downwind methodology that considers the dominant wind path, topic to value constraints.

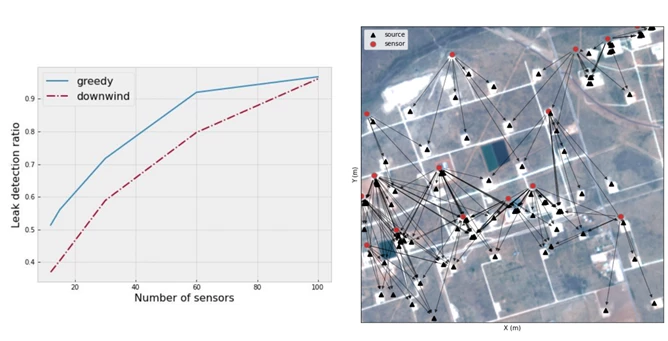

As well as, Microsoft gives a validation module to judge the efficiency of any candidate sensor placement technique. Operators can consider the marginal features supplied by using further sensors within the community, by means of sensitivity evaluation as proven in Determine 4 beneath.

Determine 4: Left: Enhance in leak protection with quite a lot of sensors. By rising the variety of sensors which can be obtainable for deployment, the leak detection ratio (i.e., the fraction of detected leaks by deployed sensors) will increase. Proper: Supply protection for 15 sensors. The arrows map every sensor (purple circles) to the sources (black triangles) that it detects.

Finish-to-end information pipeline for methane IoT sensors

To attain steady monitoring of methane emissions from oil and fuel belongings, Microsoft has carried out an end-to-end answer pipeline the place streaming information from IoT Hub is ingested right into a Bronze Delta Lake desk leveraging Structured Streaming on Spark. Sensor information cleansing, aggregation, and transformation to algorithm information mannequin are performed and the resultant information is saved in a Silver Delta Lake desk in a format that’s optimized for downstream AI duties.

Methane leak detection is carried out utilizing uni- and multi-variate anomaly detection fashions for improved reliability. As soon as a leak has been detected, its severity can also be computed, and the emission supply attribution and quantification algorithm then identifies the seemingly supply of the leak and quantifies the leak price.

This occasion data is shipped to the Accenture Work Order Prioritization module to set off applicable alerts primarily based on the severity of the leak to allow well timed remediation of fugitive or venting emissions. The quantified leaks can be recorded and reported utilizing instruments such because the Microsoft Sustainability Supervisor app. The person elements of this end-to-end pipeline are described within the sections beneath and illustrated in Determine 5.

Determine 5: Finish-to-end IoT information pipeline that runs on Microsoft Azure demonstrating methane leak detection, quantification, and remediation capabilities.

Digital twin for methane IoT sensors

Knowledge streaming from IoT sensors deployed within the discipline must be orchestrated and reliably handed to the processing and AI execution pipeline. Microsoft’s answer creates a digital twin for each sensor. The digital twin contains a sensor simulation module that’s leveraged in several phases of the methane answer pipeline. The simulator is used to check the end-to-end pipeline earlier than discipline deployment, reconstruct and analyze anomalous occasions by means of what-if situations and allow the supply attribution and leak quantification module by means of a simulation-based, inverse modeling method.

Anomaly (leak) detection

A methane leak at a supply may manifest as an uncommon rise within the methane focus detected at close by sensor places that require well timed mitigation. Step one in direction of figuring out such an occasion is to set off an alert by means of the anomaly detection system. A severity rating is computed for every anomaly to assist prioritize alerts. Microsoft gives the next two strategies for time sequence anomaly detection, leveraging Microsoft’s open-source SynapseML library, which is constructed on the Apache Spark distributed computing framework and simplifies the creation of massively scalable machine studying pipelines:

- Univariate anomaly detection: Primarily based on a single variable, for instance, methane focus.

- Multivariate anomaly detection: Utilized in situations the place a number of variables, together with methane focus, wind velocity, wind path, temperature, relative humidity, and atmospheric strain, are used to detect an anomaly.

Publish-processing steps are carried out to reliably flag true anomalous occasions in order that remedial actions will be taken in a well timed method whereas decreasing false positives to keep away from pointless and costly discipline journeys for personnel. Determine 6 beneath illustrates this function in Accenture’s MEMP: the ‘hover field” over Sensor 6 paperwork a complete of seven alerts leading to simply two work orders being created.

Determine 6: MEMP dashboard visualizing alerts and ensuing work orders for Sensor 6.

Emission supply attribution and quantification

As soon as deployed within the discipline, methane IoT sensors can solely measure compound alerts within the proximity of their location. For an space of curiosity that’s densely populated with potential emission sources, the problem is to determine the supply(s) of the emission occasion. Microsoft gives two approaches for figuring out the supply of a leak:

- Space of affect attribution mannequin: Given the sensor measurements and site, an “space of affect” is computed for a sensor location at which a leak is detected, primarily based on the real-time wind path and asset geo-location. Then, the asset(s) that lie inside the computed “space of affect” are recognized as potential emissions sources for that flagged leak.

- Bayesian attribution mannequin: With this method, supply attribution is achieved by means of inversion of the methane dispersion mannequin. The Bayesian method contains two principal elements—a supply leak quantification mannequin and a probabilistic rating mannequin—and might account for uncertainties within the information stemming from measurement noise, statistical and systematic errors, and gives the almost certainly sources for a detected leak, the related confidence stage and leak price magnitude.

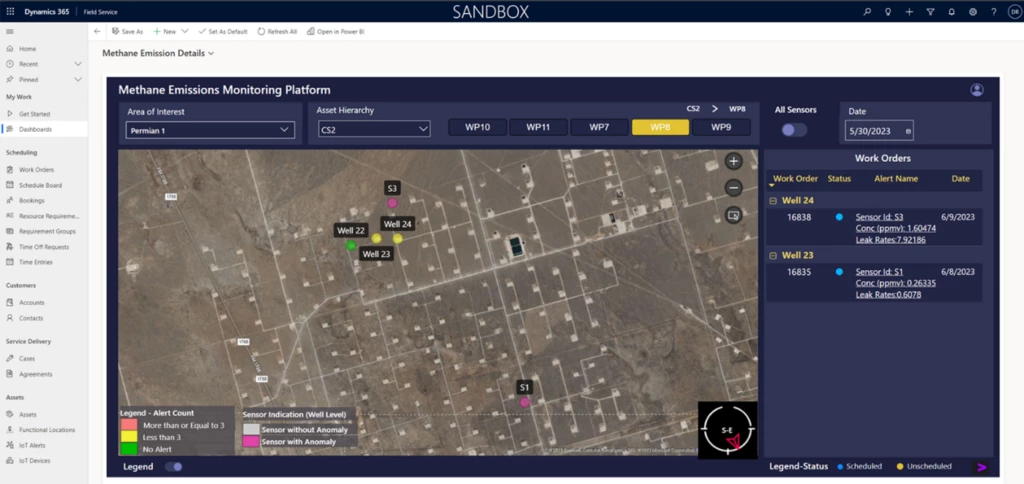

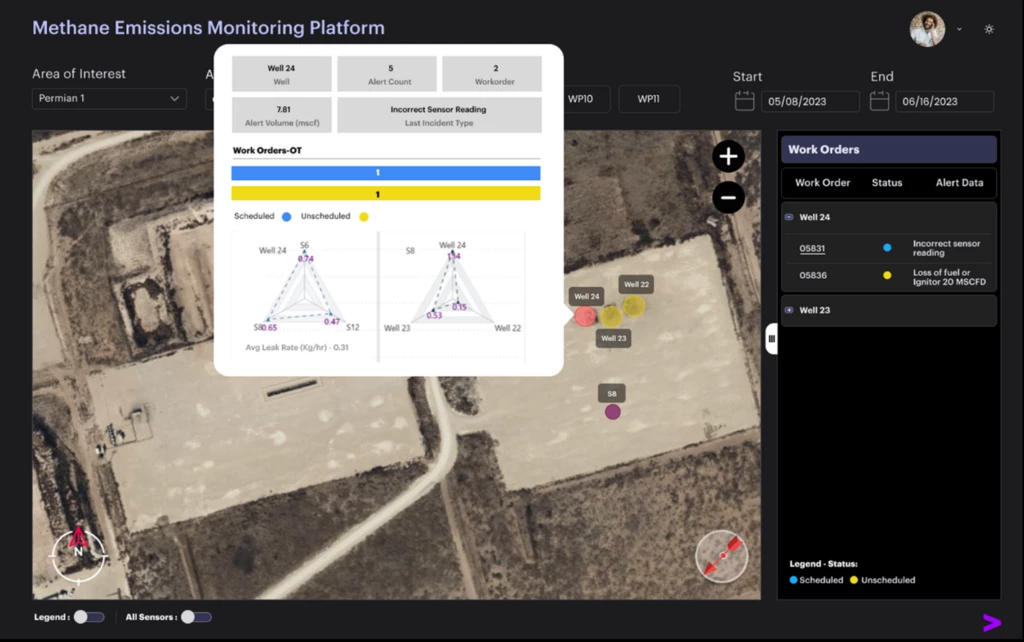

Contemplating the excessive variety of sources, low variety of sensors, and the variability of the climate, this poses a posh however extremely priceless inverse modeling drawback to resolve. Determine 7 gives perception relating to leaks and work orders for a specific nicely (Properly 24). Particularly, diagrams present well-centric and sensor-centric assessments that attribute a leak to this nicely.

Determine 7: Leak Supply Attribution for Properly 24.

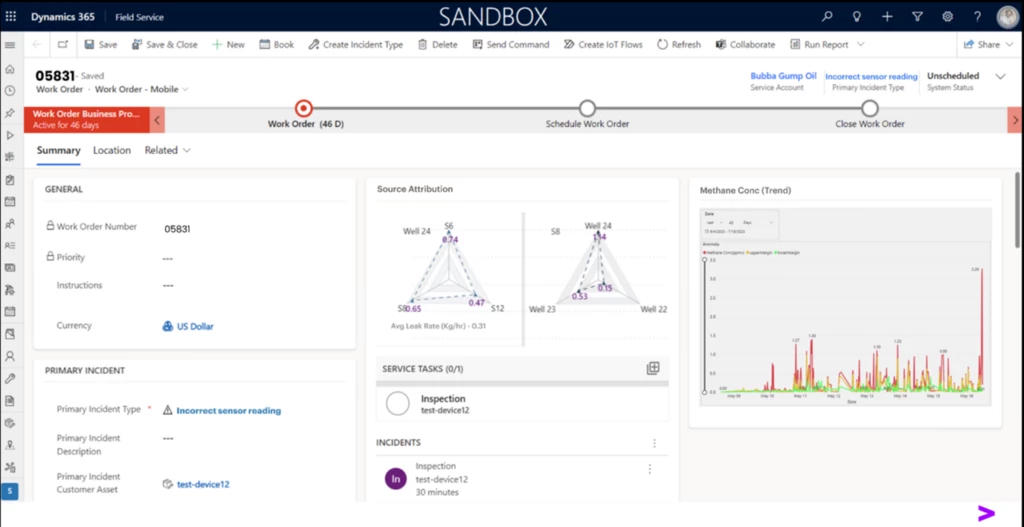

Additional, Accenture’s Work Order Prioritization module utilizing Microsoft Dynamics 365 Area Service utility (Determine 8) permits Power operators to provoke remediation measures beneath the Leak Detection and Remediation (LDAR) paradigm.

Determine 8: Dynamics 365 Work Order with emission supply attribution and CH4 focus development information embedded.

Trying forward

In partnership with Microsoft, Accenture is trying to proceed refining MEMP, which is constructed on the superior AI and statistical fashions introduced on this weblog. Future capabilities of MEMP look to maneuver from “detection and remediation” to “prediction and prevention” of emission occasions, together with enhanced occasion quantification and supply attribution.

Microsoft and Accenture will proceed to spend money on superior capabilities with an eye fixed towards each:

- Integrating business requirements platforms comparable to Azure Knowledge Supervisor for Power (ADME) and Open Footprint Discussion board to allow each publishing and consumption of emissions information.

- Leveraging Generative AI to simplify the consumer expertise.

Be taught extra

Case examine

Duke Power is working with Accenture and Microsoft on the growth of a brand new know-how platform designed to measure precise baseline methane emissions from pure fuel distribution programs.

Accenture Methane Emissions Monitoring Platform

Extra data relating to Accenture’s MEMP will be present in “Greater than sizzling air with methane emissions”. Further data relating to Accenture will be discovered on the Accenture homepage and on their power web page.

Microsoft Azure Knowledge Supervisor for Power

Azure Knowledge Supervisor for Power is an enterprise-grade, totally managed, OSDU Knowledge Platform for the power business that’s environment friendly, standardized, simple to deploy, and scalable for information administration—ingesting, aggregating, storing, looking, and retrieving information. The platform will present the size, safety, privateness, and compliance anticipated by our enterprise clients. The platform affords out-of-the-box compatibility with main service firm purposes, which permits geoscientists to make use of domain-specific purposes on information contained in Azure Knowledge Supervisor for Power with ease.

Associated publications and convention displays

Supply Attribution and Emissions Quantification for Methane Leak Detection: A Non-Linear Bayesian Regression Strategy. Mirco Milletari, Sara Malvar, Yagna Oruganti, Leonardo Nunes, Yazeed Alaudah, Anirudh Badam. The 8th Worldwide On-line & Onsite Convention on Machine Studying, Optimization, and Knowledge Science.

Surrogate Modeling for Methane Dispersion Simulations Utilizing Fourier Neural Operator. Qie Zhang, Mirco Milletari, Yagna Oruganti, Philipp Witte. Offered on the NeurIPS 2022 Workshop on Tackling Local weather Change with Machine Studying.

1https://local weather.nasa.gov/information/3246/nasa-says-2022-fifth-warmest-year-on-record-warming-trend-continues/