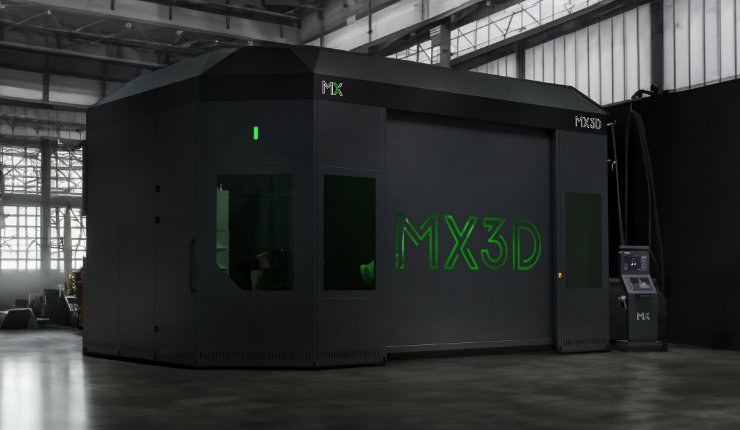

MX3D has introduced the launch of the MX Metallic AM System, a brand new turnkey robotic steel 3D printer for the creation of enormous and authorized steel elements, at Formnext Discussion board Austin. The corporate says it permits MX3D’s clients to cost-effectively substitute forged and solid elements with “considerably improved” lead time and high quality.

The printer operates on a number of adjustable construct plates, together with a heavy-duty 2-axis positioner, and manufactures elements that weigh 5 tons or extra. The system has a construct quantity of 6 x 1.5 x 3.5 metres. The system additionally consists of an 8-axis heavy-duty industrial robotic setup, excessive productiveness energy supply and the MX3D 24/7 automation bundle.

The system contains a totally upgraded MetalXL 4.0 bundle in line with the corporate, the newest model of the MX3D’s MetalXL workflow software program and management system. MX3D says this helps new productiveness instruments, dynamic sensors and lively closed-loop processes to push autonomous 24/7 3D printing of certified industrial elements to the subsequent degree.

“A number of of our clients see alternatives for making use of WAAM on a lot greater elements. Particularly within the power and maritime business the place they’ll substitute massive casted or solid elements with 3D printed elements to speed up the lead time, convey down price and reshore manufacturing of essential elements,” mentioned Gijs van der Velden, CEO of MX3D. “Because the launch of MetalXL and the M1, now we have obtained many buyer requests about whether or not we might provide them with a system able to printing radically bigger elements. The MX Metallic AM system is the reply to this name. Now clients also can print very massive and further heavy licensed steel elements in-house, accelerating 24/7 automation and operational excellence.”

In accordance the corporate, the MX Metallic AM System was developed primarily based on requests by varied industrial clients working within the power manufacturing and maritime industries to print larger-scale steel elements.

The corporate says that the brand new system is a completely customisable robotic system. It says customers can configure their excellent system for 3D printing massive, heavy, and customized steel elements utilising manufacturers similar to ABB and KUKA robotics and Fronius’ superior welding tools.

MX3D says that the built-in productiveness instruments similar to an computerized tip changer, lively cooling and superior sensors within the MetalXL Management System drive excessive print high quality at excessive pace and management. The corporate says the system might be optimised by heavy-duty-cycle energy sources to attain larger print speeds ay >10kg/hr deposition price, and configured for multi-material printing of assorted steel alloys.

The MX Metallic AM System might be additional expanded by extra sensors together with thermal cameras, 3D scanner, weld pool digicam and acoustic emission sensors.

Thomas Van Glabeke, CPO of MX3D mentioned: “The MX Metallic AM System is a formidable manufacturing system and by far the biggest AM system MX3D launched to the market. It definitely is the heavyweight champion of steel 3D printing. We particularly configured it for our clients within the heavy business markets, and we engineered it to make sure pace, high quality, and cost-effectiveness for the manufacturing of large-scale steel elements.

“The brand new MetalXL 4.0 is a big software program replace and pushes superior toolpathing to a different degree. Pair this with the heavy robotic capabilities of the MX Metallic AM System, and you’ll be able to produce complicated elements of a number of tons. Given the all-new parameter dashboard and rhe new sensor packages, it has by no means been simpler to unlock the excessive productiveness degree for steady 24/7 printing. We’re very proud that MX3D as soon as once more raises the requirements of large-scale steel printing, by persistently delivering tailor-made software program and {hardware} options that redefine the business.”