Researchers from Monash College (Australia) and the Arts et Métiers Institute of Expertise (France), have printed a paper on tissue engineering within the Superior Purposeful Supplies journal. This research highlights a brand new method that mixes top-down co-extrusion and bottom-up 3D printing to create biomaterials with intricate layered structure.

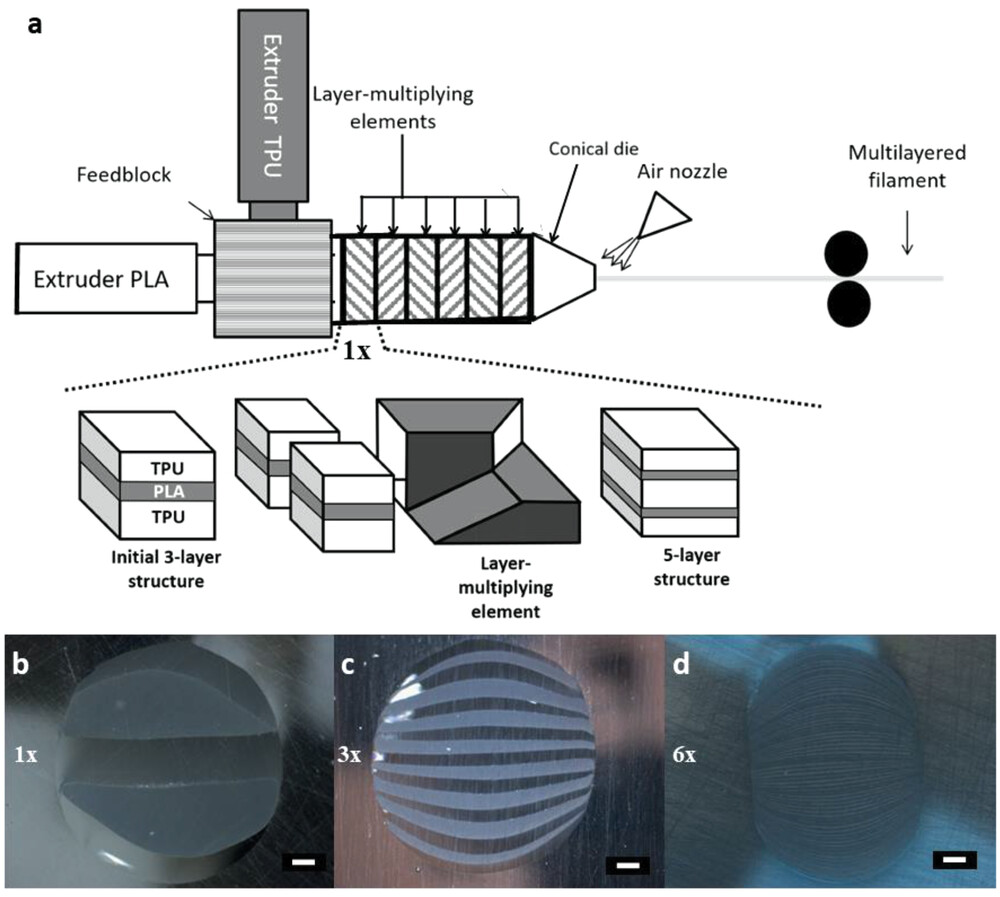

Historically, mimicking complicated organic buildings whereas fostering cell progress has confirmed difficult. Nevertheless, the research presents a two-step technique: using multilayer co-extrusion to supply alternating layers of biodegradable poly(lactic acid) (PLA) and elastic thermoplastic polyurethane (TPU), after which utilizing 3D printing to construct refined tissue engineering scaffolds.

Importantly, this method maintains the layered construction throughout printing, leading to steady interfaces between polymer phases. By adjusting the co-extrusion course of, researchers have achieved filaments with various layer thicknesses, enabling the creation of 3D constructs with nanoscale polymer layers. Mechanical assessments demonstrated improved properties in sure architectures, mixing the strengths of each PLA and TPU.

The research’s influence extends to cardiac tissue engineering, the place the multilayered scaffolds influenced the alignment, morphology, and performance of rat coronary heart muscle cells (cardiomyocytes). The analysis holds important promise for coronary heart well being, as optimum cardiomyocyte progress and performance are very important.

Past its cardiovascular functions, the research’s revolutionary fusion of fabrication methods presents a flexible method relevant to various tissue engineering endeavors, from bone regeneration to wound therapeutic.

You may learn the complete paper, titled “Fabrication of Architectured Biomaterials by Multilayer Co-Extrusion and Additive Manufacturing” at this hyperlink.

Supply: onlinelibrary.wiley.com

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to join our weekly additive manufacturing e-newsletter to get all the newest tales delivered proper to your inbox.