Pondering of how one can pace up your meeting traces? These IoT-based soldering irons with

easy-to-use menus, steady temperature, and sleep mode options may assist. This text discusses some revolutionary soldering tendencies that may elevate meeting to a brand new stage

Soldering is a crucial a part of the manufacturing chain or the meeting line that may utterly change the fortune of a producing group. With the brand new tendencies and improvements within the electronics trade, the standard soldering stations in an meeting line have to be up to date.

There are quite a few improvements going down within the enviornment of soldering. For instance, the meeting traces can now be managed by simply tracing the efficiency and precision of the soldering work. Not simply that, there are particular soldering ideas being launched for hard-to-reach areas in a chip or a system. These improvements, if utilized effectively, can utterly change the tempo of manufacturing for good.

Many soldering iron producers at the moment are designing their irons with ergonomics in thoughts. Ergonomic soldering irons are designed to suit comfortably in your hand, decreasing the danger of pressure or harm. They typically function snug grips, adjustable stands, and different equipment that make them simpler and safer to make use of. A shorter grip-to-tip distance permits extra management.

Key Components to Think about When Buying Soldering Tools

Allow us to take a look at among the improvements, so you can also make an knowledgeable determination when buying your soldering gear.

Warmth Management

Warmth management manages temperature throughout numerous parts as increased temperatures are wanted for soldering bigger or thicker parts whereas decrease temperatures are wanted for extra delicate work or for working with heat-sensitive parts.

The ‘Fast Warmth’ function in PX-280 soldering iron from Goot reaches a temperature in time akin to that of middle-class soldering stations. The soldering temperature ranges from 200 to 500°C. It reaches 350°C in simply 30 seconds with a normal tip. With a high-power heater and sensor, there’s virtually no temperature fluctuation throughout heavy-duty steady operation.

The WE 1010 soldering iron from Weller Instruments gives wonderful temperature stability. It incorporates a temperature lock that stabilizes warmth ranges and prevents them from wavering. The gadget can function at between 100 and 450°C. It retains temperatures at plus or minus six levels Celsius of the supposed temperature.

Whereas most soldering irons begin at 100°C, the B-Iron from JBC Instruments gives a minimal of 30°C, thereby decreasing the danger of damaging parts and enhancing the standard of soldering and desoldering.

Ideas

Along with temperature management of a soldering iron, another elements may have an effect on warmth switch and management, reminiscent of the dimensions and form of the tip, the sort and thickness of the fabric being soldered, and the quantity of solder getting used. Correct warmth management is crucial for attaining a profitable and dependable solder joint.

Firms provide quite a lot of soldering ideas that allow precision whereas working. The following tips differ as per their purposes; hoof ideas are meant for bigger quantities of solder, knife tricks to attain into the slotted cavities and edges, chisel ideas are multi-purpose solder ideas, and conical ideas are for precision work. Firms like JBC and Weller provide a broad vary of ideas to select from.

If you’re shopping for ideas for an present soldering station, guarantee that the guidelines are constructed to match and function along with your gear. Some ideas are supposed for heavy-duty use whereas others are supposed for light-duty and precision work.

Sleep Function

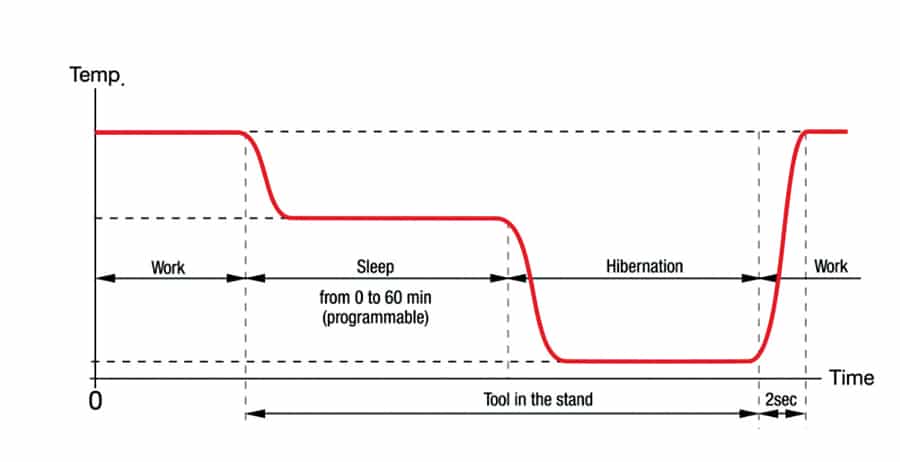

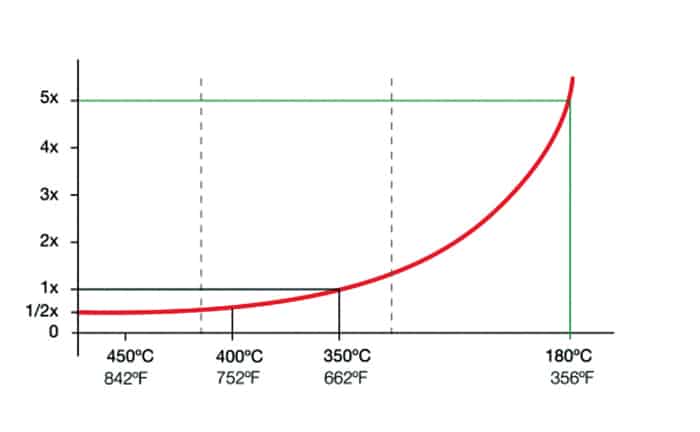

Tip life will increase exponentially through the use of decrease temperatures. Utilizing the sleep mode, the common temperature could be additional diminished, which might prolong a tip’s life 5 occasions. The sleep mode routinely lowers the tip temperature beneath the solder melting level when the device rests in its stand. It prevents the dissolution of the tip’s iron coating into molten solder.

After a configurable interval of device inactivity within the stand (10 minutes manufacturing unit default), the device enters into hibernation mode, which cuts off the ability provide and lets the tip attain room temperature, thus stopping oxidation, and saving power. A number of the merchandise that supply this function are WE 1010 soldering iron from Weller Instruments, JBC’s B-iron, and PX-280 by Goot (Taiyo Electrical Ind. Co.).

| Components Affecting Tip Life |

|

Incorrect method: An excessive amount of strain on the floor to solder may cause tip or plate breakage. Don’t use it as a pointed object or a screwdriver. Selecting the most important tip doable for every software and dealing on the lowest doable temperature may do the factor. Iron oxide doesn’t moist nor switch temperature effectively (dewetting): The upper the temperature, the larger the danger of oxidation. Preserve the guidelines at all times tinned whereas not in use and preserve them clear. |

Soldering Stations

The soldering station is the opposite half of the soldering iron. Soldering stations allow working effectivity and productiveness in a number of methods. These are usually used to maintain the soldering irons between their use.

However there may also be the necessity to concurrently use totally different soldering ideas. To allow such a transition, soldering stations are designed to interchange the instruments wanted for altering ideas.

JBC’s soldering station comes with a fast cartridge extractor connected to it. Simply place the soldering iron into the holder, pull the iron, and insert a brand new tip. It reduces idle time and will increase operator security.

Weller additionally gives one thing related. Its WE 1010 comes with a plastic knurled nut positioned on the soldering pencil by hand. The operator can flip the nut to vary the tip. This course of additionally will increase effectivity and reduces the time for finishing a job.

| Cleansing of Soldering Irons |

|

Cleansing soldering irons is a crucial a part of the entire work-rework course of as this will have an effect on the standard of tip and the growing gadget as effectively. The soldering equipment usually comes with a easy sponge that cleanses the iron, however that’s not fairly environment friendly. Shoritsu Electrical Trade, or Senpujin, has designed a cyclone kind soldering iron cleaner. A vortex-like air move is generated contained in the cleaner and dust on the soldering iron tip is eliminated with out contact. It additionally requires minimal upkeep. |

Soldering stations allow whole management over the soldering iron and the working temperature. Some superior soldering stations additionally provide calibration choices for temperature management and sensible methods that may work as a information as effectively.

For instance, JBC gives a soldering station with an easy-to-use menu, which shows instruments preset independently for every device kind and port. The system analyses the soldering course of to assist the operator choose the most effective tip for work and see the standard of every soldering joint.

Traceability

Soldering stations are being configured to handle manufacturing as effectively. The traceability function launched by Kurtz Ersa and JBC screens works with energy and temperature knowledge in actual time.

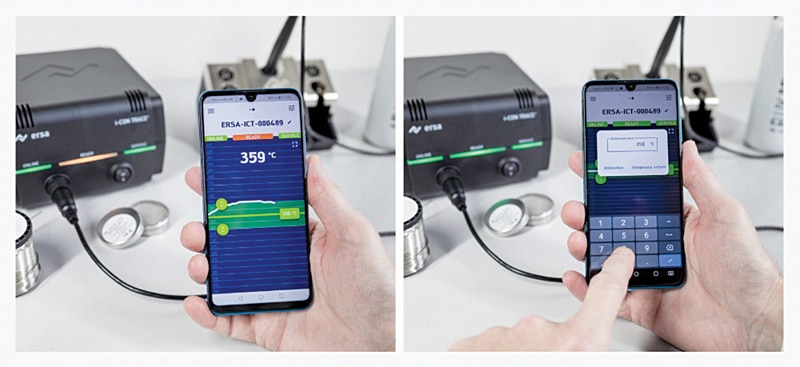

The i-CON TRACE by Kurtz-Ersa is a completely networkable soldering station with an built-in WLAN, Bluetooth, and community card. It may be absolutely built-in into MES-controlled manufacturing processes, making the entire hand-soldering course of traceable and documentable.

i-CON TRACE could be linked to a producing execution system (MES) with individually configured settings. This implies seamless integration of the i-CON TRACE into networked manufacturing processes, that are already managed by an MES.

Equally, JBC gives a Internet Supervisor function, which permits companies to handle JBC soldering stations. This lets you entry station knowledge remotely, utilizing the corporate community and/or the web from any gadget, smartphone, pill, Android, iPhone/iPad, or laptop.

Digital Know-how

Incorporating digital know-how into the soldering iron is of giant curiosity as effectively. Digital soldering irons have gotten more and more standard as a result of their accuracy and precision.

Temperature calibration, for instance, is one function embedded in digital irons. The gadget digitally calibrates the distinction between the set temperature and the tip temperature as measured by the tip thermometer.

| Cordless Irons |

|

Cordless irons are rising onto the market as they’re extraordinarily moveable and nice for hard-to-reach spots. However they don’t have limitless run time. And their batteries have to be modified over time. |

These soldering irons come geared up with an LCD display that shows the temperature and different important details about the soldering course of. The digital temperature management system ensures that the soldering iron maintains a constant temperature all through the job.

Digital soldering irons are additionally geared up with superior security options, reminiscent of computerized shut-off methods, that forestall the soldering iron from overheating and inflicting injury.

Lastly, soldering irons have gotten extra specialised to fulfill particular trade wants. For instance, there at the moment are soldering irons designed particularly for jewellery making, circuit board restore, and automotive work. These specialised soldering irons include options which are tailor-made to the precise duties they’re designed for, making them extra environment friendly and efficient.

You may also verify the fast information to pick the suitable soldering iron.

This text has been put collectively by Jay Soni, an electronics fanatic at EFY