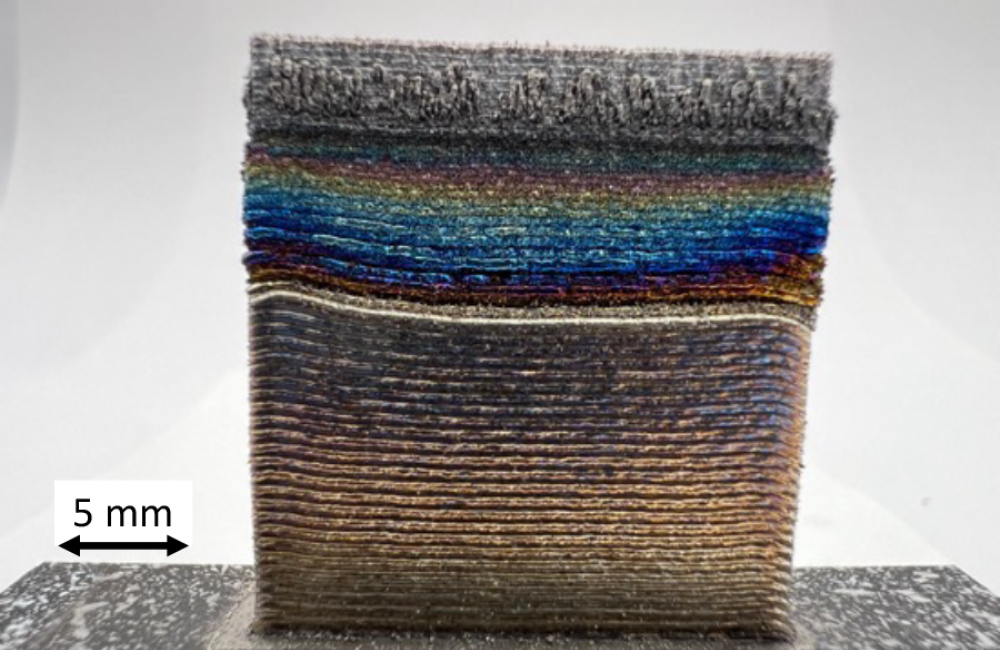

Researchers on the Division of Power’s Oak Ridge Nationwide Laboratory (ORNL) have developed a brand new expertise for additive manufacturing of composite metallic components. The brand new approach permits for the design of compositionally graded composite components that transition seamlessly from high-strength superalloys to refractory alloys able to withstanding excessive temperatures, eliminating the necessity for welding.

The important thing to this course of lies within the “secret sauce” – a powder composed of a 3rd transition alloy with light-weight or high-temperature traits. Utilizing directed vitality deposition, researchers deposit completely different powder compositions in an inert argon atmosphere whereas adjusting the deposition charge alongside the best way.

“It’s like cooking- you principally have completely different elements,” stated lead researcher, Soumya Nag.

“So, when you’ve got extra pasta on one facet and extra risotto on the opposite facet, how do you constantly change from a pasta to a risotto? You modify the elements as you progress alongside from one finish to a different, and that’s precisely what we do,” Nag stated.

Historically, structural functions contain utilizing a single alloy composition for fabricating parts in harsh environments, which might be costly and compromise efficiency. Alternatively, welded components created from dissimilar supplies are used for parts requiring diversified properties, resulting in abrupt interfaces and decreased efficiency.

On this analysis, scientists efficiently joined non-weldable superalloys with refractory alloys by making a non-linear gradient pathway utilizing computational thermodynamics and experimental information. The group validated their computational alloy design by analyzing stress states with neutron diffraction-based research.

The potential functions for this expertise are huge, together with rocket engines for area, aerospace manufacturing, fusion and fission reactor fabrication, marine-related makes use of, and renewable vitality programs – primarily any discipline the place excessive environments exist.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to join our weekly additive manufacturing publication to get all the most recent tales delivered proper to your inbox.