Ever because the discovery of the two-dimensional type of graphite (known as graphene) nearly twenty years in the past, curiosity in 2D supplies and their particular bodily properties has skyrocketed. Famously, graphene was produced by exfoliating bulk graphite utilizing sticky tape. Though it was ok for a Nobel Prize, this technique has its drawbacks.

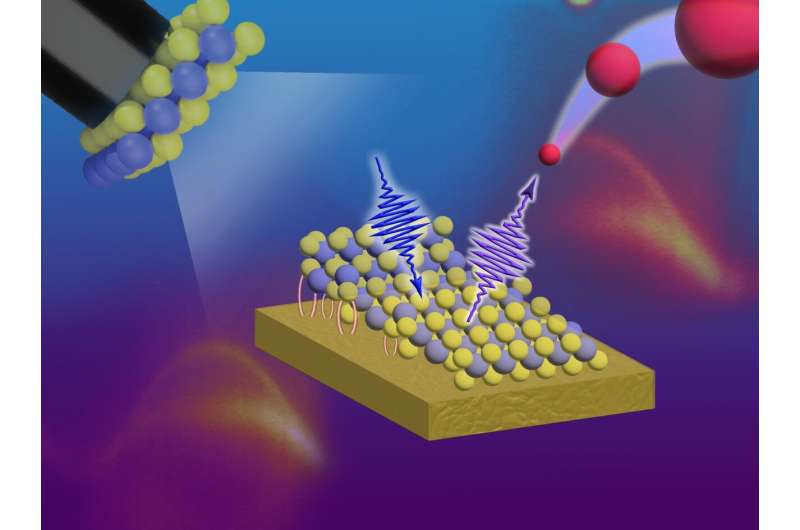

A global crew of floor scientists has now developed a easy technique to provide giant and really clear 2D samples from a spread of supplies utilizing three completely different substrates. Their technique, kinetic in situ single-layer synthesis (KISS) is described within the journal Superior Science on June 1.

Two-dimensional supplies have bodily properties that aren’t shared by bulk materials. The confinement of cost carriers is one purpose for this. There are two methods to provide these 2D supplies: exfoliating a bigger crystal or rising a 2D layer. Exfoliation means peeling off layers from a bigger crystal till you might be left with only one layer.

“This course of is time-consuming and requires particular abilities and gear,” says Antonija Grubišić-Čabo, a floor scientist on the College of Groningen (the Netherlands) and first writer of the Superior Science paper. “Moreover, it typically leads to very small flakes, whereas the adhesive tape that’s used can go away polymers on their surfaces.”

Rising 2D movies is one other method. This permits the manufacturing of enormous samples below managed situations. “Nonetheless, it typically takes a variety of time to work out how one can develop such 2D supplies. And the method does not at all times lead to an ideal layer,” says Grubišić-Čabo. Along with final writer Maciej Dendzik, she assembled a “dream crew” of colleagues, lots of whom had beforehand labored collectively at Aarhus College (Denmark) as Ph.D. college students, to develop a easy method for the manufacturing of 2D supplies.

“We knew of some experiments by which gold movies had been used to exfoliate bulk materials. However these had been primarily carried out in air, which signifies that this method shouldn’t be very appropriate for air-sensitive supplies, or for floor science analysis,” Grubišić-Čabo notes.

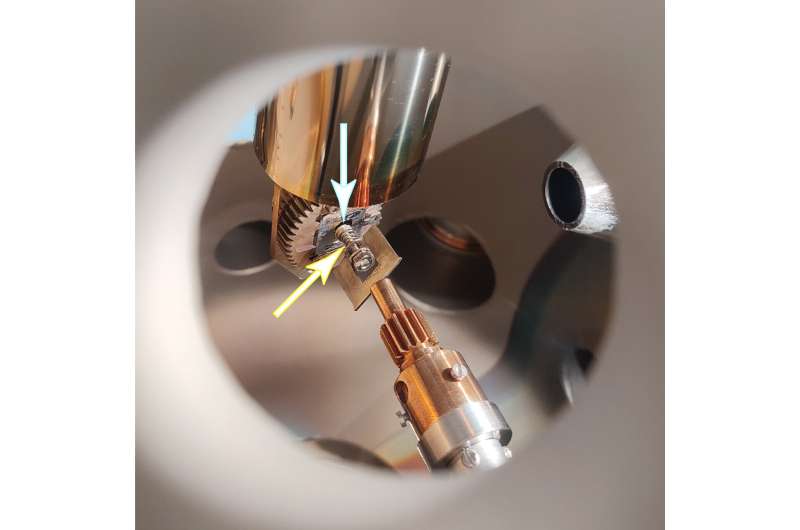

The crew wished a way that may permit the manufacturing of air-sensitive 2D supplies on a spread of substrates. Of their first try, they used a gold crystal in a excessive vacuum chamber. “We mainly slammed the crystal on bulk materials and found {that a} good 2D layer caught to the gold,” says Grubišić-Čabo. Why this occurs shouldn’t be but clear, however the crew suspects that the bond with the gold is stronger than the Van der Waals drive that retains the layers within the bulk crystal collectively.

They’ve constructed on this primary experiment, including a spring to the stage with the bulk materials which acts as a shock absorber and thus permits higher management of the affect of the gold crystal. Moreover, the crew confirmed that each silver and the semiconductor germanium could possibly be used as a substrate to peel off 2D supplies.

“Gold crystals are a normal function in floor science labs, the place they’re used within the calibration of devices, for instance. Scientists don’t love to break these crystals, however that did not occur in these experiments,” says Grubišić-Čabo. “And we’ve got since modified the protocol to make use of single crystal gold skinny movies. This has the added benefit of having the ability to dissolve the gold in order that we will isolate the 2D pattern, so long as it’s steady in air or liquid.”

These remoted samples could also be used for the subsequent stage: constructing gadgets from the 2D supplies that can be produced utilizing the KISS method. “This isn’t but potential, however we’re engaged on it,” says Grubišić-Čabo. “So, what we do have is a way to provide very clear, giant 2D samples in a quite simple method, which permits us to create air-sensitive 2D supplies. Moreover, our method makes use of commonplace gear that’s current in nearly each floor science laboratory.”

Extra info:

Antonija Grubišić‐Čabo et al, In Situ Exfoliation Technique of Giant‐Space 2D Supplies, Superior Science (2023). DOI: 10.1002/advs.202301243

Supplied by

College of Groningen

Quotation:

Producing giant, clear 2D supplies made straightforward: Simply ‘KISS’ (2023, June 1)

retrieved 1 June 2023

from https://phys.org/information/2023-05-large-Second-materials-easy.html

This doc is topic to copyright. Other than any truthful dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.