Digital steel powder market qualloy and AddiMap, the “world’s first” digital market for 3D printing course of parameters, have introduced a strategic collaboration.

This partnership will see each marketplaces mix into one complete platform. This platform encompasses each the sourcing of steel powders and the accessibility of validated 3D printing parameters. It’s claimed that this mixed providing will allow customers to get probably the most out of 3D printing, accelerating the industrialization and democratization of steel additive manufacturing.

“We’re thrilled to collaborate with AddiMap and mix our strengths to create a complete resolution for the AM trade,” commented Yannik Wilkens, Co-founder of qualloy. “By means of this partnership, we purpose to additional improve the consumer expertise by offering seamless entry to AddiMap’s in depth printing parameters database, empowering customers to unlock the total potential of additive manufacturing.”

Combining two digital marketplaces

This collaboration is alleged to convey collectively two “cutting-edge” platforms that “completely” complement one another.

qualloy’s digital steel powder market supplies a platform the place patrons and sellers can simply join and conduct transactions. To attain this, qualloy leverages an clever search algorithm. That is mentioned to streamline the powder sourcing course of, permitting customers to find the best steel powders for his or her wants from a variety of licensed international suppliers.

Furthermore, qualloy permits customers to freely swap between completely different steel powder producers. Thus, customers can optimize value, supply time, and high quality, whereas sustaining a clear and environment friendly procurement course of.

In line with Wilkens, “With qualloy, we now have simplified the marketplace for steel powders, enabling patrons to search out the proper match for his or her printers shortly.”

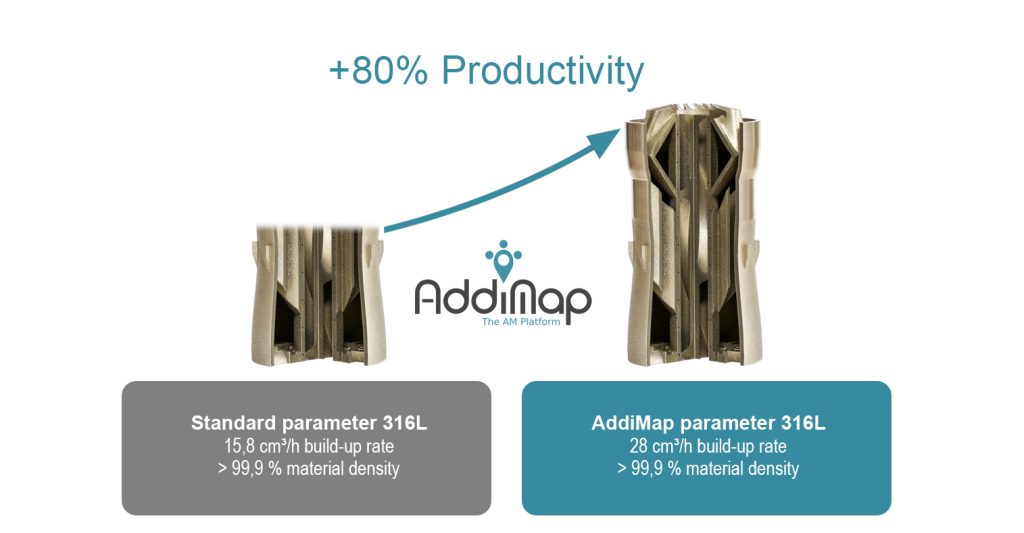

Developed by steel 3D printing service bureau Rosswag Engineering and software program agency NuCOS, AddiMap was beta-launched final 12 months. AddiMap’s plug-and-play printing parameter platform is alleged to considerably cut back the time and assets required for parameter improvement and qualification processes.

By accessing AddiMap’s parameter library, customers can transition from digital fashions to bodily merchandise with out requiring in depth parameter research. AddiMap declare that their providing accelerates the industrialization of steel additive manufacturing by way of the democratization of information and assets.

Gregor Graf, Initiator of AddiMap, has emphasised the significance of cooperation and cost-reduction in accelerating the adoption of steel 3D printing. “Cooperation is the important thing to leverage the total potential of Metallic AM. Much less prices and extra supplies will result in quicker industrial adoption.”

“With AddiMap, we purpose to supply customers with an enormous vary of course of parameters, enabling them to extend productiveness, optimize properties, discover new supplies and streamline their AM operations,” added Graf.

Each corporations state that this collaboration marks a milestone within the additional simplification of additive manufacturing, streamlining the procurement of steel powders and offering entry to a complete 3D printing parameter database. These corporations declare to be driving the industrialization and democratization of additive manufacturing, selling development and innovation in consequence.

Industrializing additive manufacturing

Accelerating the industrialization of additive manufacturing is a standard theme throughout the present 3D printing trade. Earlier this 12 months, international requirements developer ASTM Worldwide’s Additive Manufacturing Middle of Excellence (AM CoE) added quite a lot of new members to its Consortium for Supplies Knowledge and Standardization (CMDS) program. Provided that 3D printing supplies are key to the additive manufacturing workflow, a notable purpose of the CMD is to “speed up the industrialization and full adoption of AM applied sciences.”

Final 12 months, multinational automotive producer BMW introduced the success of its Industrialisation and Digitalisation of Additive Manufacturing (IDAM) undertaking. First launched in 2019, the initiative established two digitally-connected automotive 3D printing manufacturing strains in Bann and Munich. These manufacturing suites can now produce round 50,000 elements per 12 months, whereas working independently with out the necessity for handbook inputs.

Subscribe to the 3D Printing Business e-newsletter to make sure you sustain with the newest 3D printing information. You can even observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a choice of accessible roles and kickstart your profession.

Featured picture reveals the qualloy and AddiMap partnership banner. Picture by way of Rosswag Engineering.