Hyderabad-based Birla Institute of Expertise & Science (BITS) researchers have unveiled a novel strategy to detect and monitor diabetes.

By the utilization of 3D printing expertise, the researchers crafted a transportable gadget with the power to investigate glucose and lactate concentrations current in sweat samples. Documented in Elsevier and with backing from the Telangana State Council of Science & Expertise (TSCOST), the analysis demonstrated the inherent promise of sweat as a key analytical substrate, particularly for the continuing monitoring of glucose ranges in these affected by kind 1 and kind 2 diabetes.

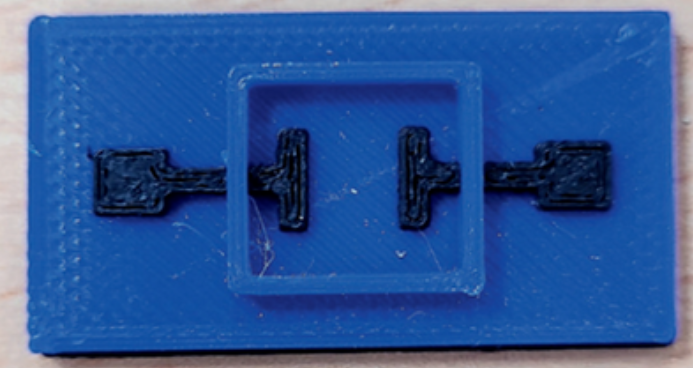

As outlined by Professor Sanket Goel, crafting this gadget concerned a fusion of 3D printing, CO2 laser expertise, and electrodes constructed from graphene. Moreover, college students had been liable for extracting graphene in-house as a part of the event. “The system’s non-invasive nature eliminates the necessity for blood samples to gauge glucose ranges. It may well work with blood too. However, the novel innovation is that it takes sweat pattern to detect lactate focus,” the professor informed Occasions of India (TOI.)

A low-cost and efficient different

The professor emphasised the mechanism by means of which this gadget identifies lactate ranges. He stated this gadget operates primarily based on Electrochemiluminescence (ECL). The gadget capabilities by emitting {an electrical} sign upon the introduction of sweat as enter. Subsequently, a chemical response happens, ensuing within the emission of sunshine as an output. By the measurement of sunshine depth, it turns into potential to establish the focus of lactate.

Moreover, by additionally utilizing machine studying, researchers had been capable of decide lactate concentrations essential for therapy. They designed a transportable gadget connecting to smartphones, displaying metabolite information by way of an app. In line with the researchers, the gadget is being developed right into a wearable model for ongoing monitoring. In collaboration with an organization (at present nameless), they plan to launch the gadget in 6-9 months, with an estimated value of Rs. 300-400 ($3.63 – $4.84) per unit in bulk.

3D printing enhances diabetes monitoring and therapy

Researchers on the UK’s Staffordshire College developed a cheap 3D printed insole with built-in sensing capabilities to forestall diabetic foot ulcers. The 3D printed insoles used tunable buildings to detect stress factors whereas strolling, aiding clinicians in figuring out early indicators of ulcers in weak sufferers and avoiding amputations. Comprising conjoined hexagons, the versatile TPU-based design shielded diabetic ft from stress. Over time, microstructures gathered injury, aiding in mapping weak areas. After 2,000 check cycles, the insoles proved sturdy, with a stress threshold of 252 kPa.

Researchers on the Nationwide and Kapodistrian College of Athens developed a 3D printed gadget permitting diabetics to observe blood sugar ranges utilizing solely sweat and a normal smartphone. Using a Flashforge Creator Professional 3D printer and conductive filament, the crew fabricated an electrochemical ring (or ‘e-ring’) with three plastic electrodes. As soon as related to a mini-circuit board, the sensors precisely tracked glucose ranges utilizing biomarkers, offering a much less invasive self-testing choice as in comparison with conventional glucometer needles. The strategy shifted to sweat-based biomarkers attributable to limitations in typical enzyme-based sensors. Gold-plated sensors, related to a Samsung J5 smartphone, displayed exact readings following sugar-induced “synthetic sweat” checks. This technique has the potential for accessible, exact, and in-house 3D printed glucometers.

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will have to be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Business e-newsletter or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you on the lookout for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a choice of roles within the trade.

Featured picture reveals the researchers employed machine studying to find out exact lactate concentrations. Picture by way of BITS.