Researchers from Queensland College of Expertise have performed a case examine to guage using 3D printing resins for the manufacturing of microfluidic elements for cell-based functions.

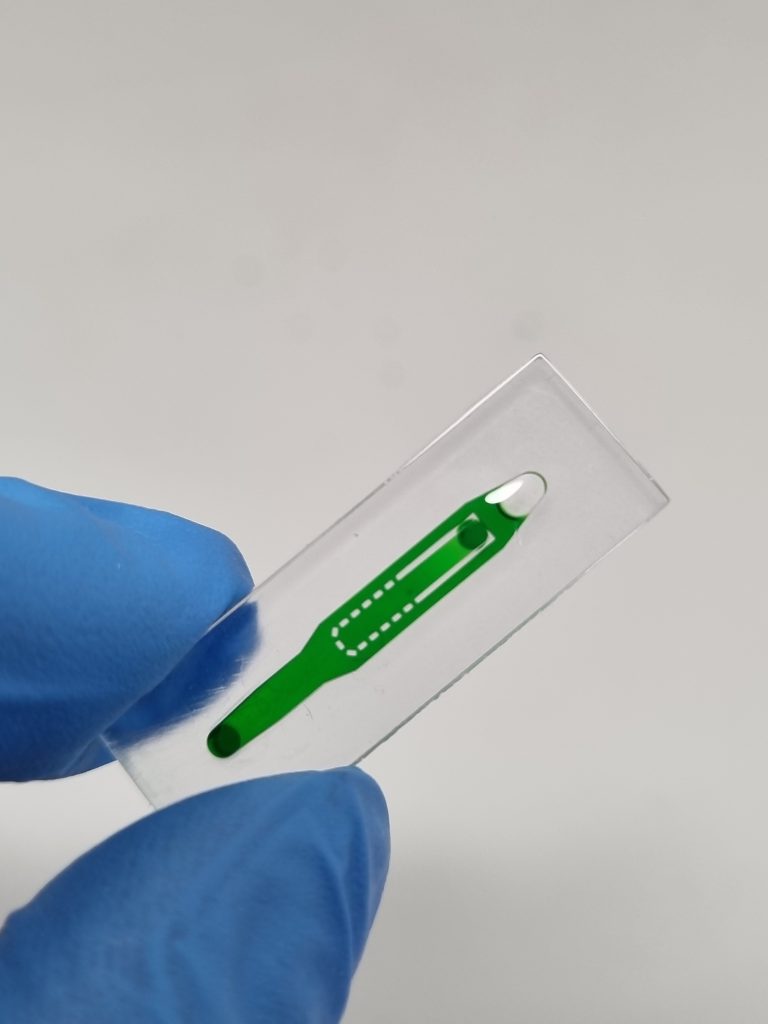

Throughout this examine, the researchers used MOIIN Excessive Temp and MOIIN Tech Clear resins from DMG Digital Enterprises along with ASIGA UV Max X27 DLP 3D printers. This know-how was leveraged to 3D print three frequent microfluidic designs: 2D monolayer tradition gadgets, pillar arrays, and constricting channels for droplet mills.

To find out whether or not these MOIIN 3D printing supplies are appropriate with cell primarily based analysis, three key standards had been evaluated, together with: advanced unibody 3D printing of microarchitecture for cell trapping and circulation manipulation; appropriate to imaging platform; and appropriate with imaging platforms reminiscent of microscopes.

Finally the examine, which was led by Louis Ong and Yi-Chin Toh, concluded that “with MOIIN Excessive Temp and MOIIN Tech Clear, the 3D printing of microfluidic channels for cell-based functions are possible. Each resins are noticed to be biocompatible and extremely amendable for microscopy imaging.”

“This remark probably opens many alternatives for fast prototyping of recent generations of microfluidic channels for biomedical functions.”

The complete case report may be accessed right here.

3D printing microfluidic gadgets

Microfluidics offers with the shifting, controlling and analyzing of liquids within the micro vary on a linear scale of lower than one millimeter.

Historically, most microfluidic system design and prototyping is reliant on PDMS mushy lithography, a way which includes molding and embossing an elastomer onto a mildew to supply microstructures. As a result of molding nature of sentimental lithography, most designs of the microfluidic channels are restricted to a single aircraft. Multiplanar channels require handbook meeting by technicians, which is time consuming and sometimes ends in a low prototyping turnover charges.

3D printing permits for the manufacturing of fluidic channels with out the necessity for further meeting steps, accelerating the prototyping turnover price of microfluidic gadgets. What’s extra, using plastic supplies permits simpler analysis translation into giant scale manufacturing processes.

The 3D printing and testing course of

AutoCAD 3D design software program from Autodesk was used to design the microfluidic gadgets, which had been fabricated at a 50 μm z-resolution. As soon as 3D printed, the elements had been immersed in an isopropyl-alcohol (IPA) tub and sonicated at 480 seconds. A syringe was used to softly flush out any resin trapped throughout the microchannels.

Subsequent, the elements had been subjected to a separate IPA tub for 3 cycles of sonication at 480 seconds per cycle. The gadgets had been then transferred to a clear IPA tank for two hours to take away any residual resin. Lastly, the clear gadgets had been blown dry and subjected to twenty minutes of warmth remedy at 60℃, earlier than being positioned in a UV cleansing chamber for 3 hours.

Each MOIIN Excessive Temp and MOIIN Tech Clear resins had been discovered to assist the fabrication of frequent microfluidic system channel geometries for cell-based experiments. Certainly, each of MOIIN’s resins efficiently produced extremely correct micro-architecture with the smallest dimension of 300 μm width at 1:3 side ratios.

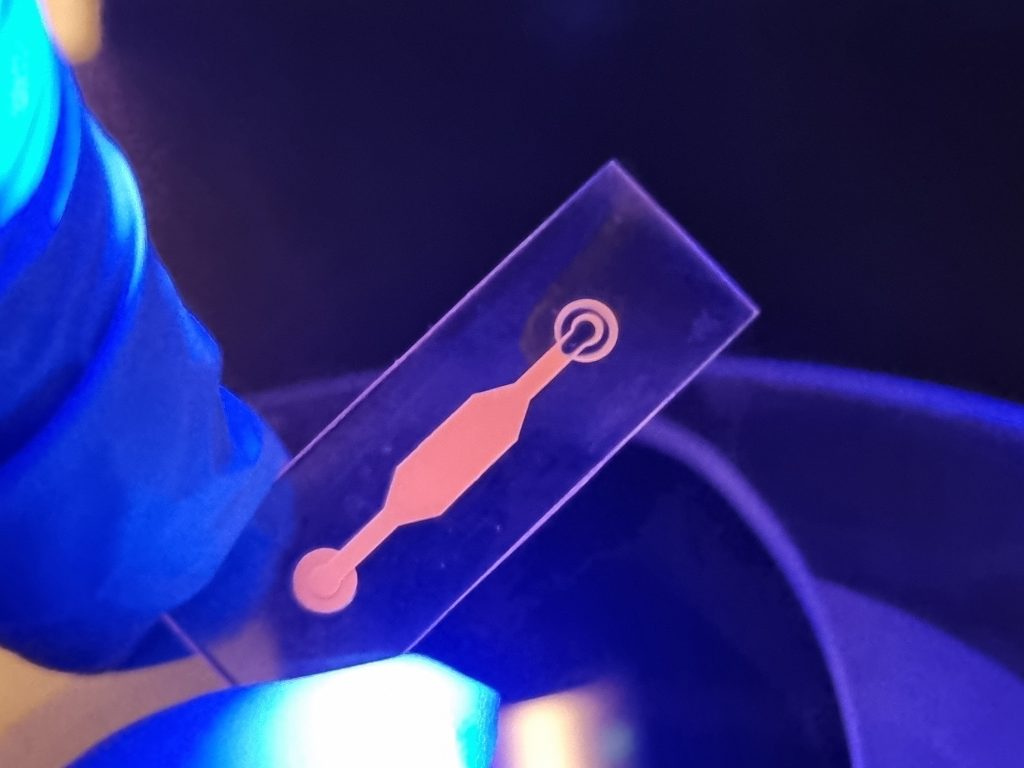

Provided that microscopy stays the go-to platform for tissue engineers and biologists conducting experiments on microfluidic gadgets, the compatibility of MOIIN’s resin in microscopy was assessed. Right here, the analysis crew centered on MOIIN Tech Clear, which has been specifically developed for 3D printing clear objects. Finally, utilizing this resin, the researchers had been capable of obtain high-resolution imaging of microchannels microarchitecture, and high-resolution particle circulation all the way down to 10X.

Moreover, the biocompatibility of each MOIIN resins with tissue monolayer cultures was investigated. Right here, the researchers 3D printed 2D tradition channels, into which liver HepG2 cell traces had been seeded. After 5 days, the researchers noticed restricted cell loss of life for each resins. As such, it was deduced that each MOIIN Excessive Temp and MOIIN Tech Clear resins are biocompatible and may assist cell-based functions inside 3D printed gadgets.

Microfluidics and 3D printing

This isn’t the primary time additive manufacturing has been leveraged for microfluidic functions. Final 12 months it was introduced that researchers from the Stevens Institute of Expertise in New Jersey had been utilizing computational modelling methods to advance microfluidics-based 3D bioprinting. It’s hoped that these methods can at some point be used to allow the manufacturing of 3D printed human organs.

Section Inc, a North Carolina-based medical 3D printing startup, introduced final 12 months that it has additionally sought to advance microfluidics 3D printing by way of a partnership with Virginia Tech. By means of this collaboration, Section’s LE3D know-how is being leveraged to develop novel microfluidic gadgets to assist researchers formulate new medical therapies for situations reminiscent of mind most cancers. The work can be mentioned to assist streamline drug discovery and well being diagnostics.

Subscribe to the 3D Printing Trade publication to maintain updated with the most recent 3D printing information. You may also comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a choice of accessible roles and kickstart your profession.

Featured picture reveals a 2D chamber produced utilizing MOIIN resin seen underneath fluorescent mild. Photograph by way of Queensland College of Expertise.