Researchers within the US have made a discovery within the subject of 3D printing with the creation of a extremely conductive metallic gel. In contrast to earlier applied sciences, this gel permits for the printing of three-dimensional metallic objects at room temperature in a single step. The gel opens up new prospects for manufacturing a variety of digital parts and units.

The method begins with an answer of micron-scale copper particles suspended in water. A small quantity of an indium-gallium alloy, which stays liquid at room temperature, is then added to the combination. By stirring, the liquid metallic and copper particles kind a metallic gel community throughout the answer. This gel-like consistency ensures a uniform distribution of copper particles all through the fabric, creating electrical pathways and stopping clogging within the printer.

“In the end, this form of four-dimensional printing – the standard three dimensions, plus time , is yet another device that can be utilized to create constructions with the specified dimensions,” stated Michael Dickey, co-corresponding creator of a paper and Professor of Chemical and Biomolecular Engineering at North Carolina State College.

“However what we discover most fun about this materials is its conductivity. As a result of the printed objects find yourself being as a lot as 97.5% metallic, they’re extremely conductive. It’s clearly not as conductive as typical copper wire, but it surely’s not possible to 3D print copper wire at room temperature. And what we’ve developed is way extra conductive than the rest that may be printed. We’re fairly excited concerning the purposes right here.”

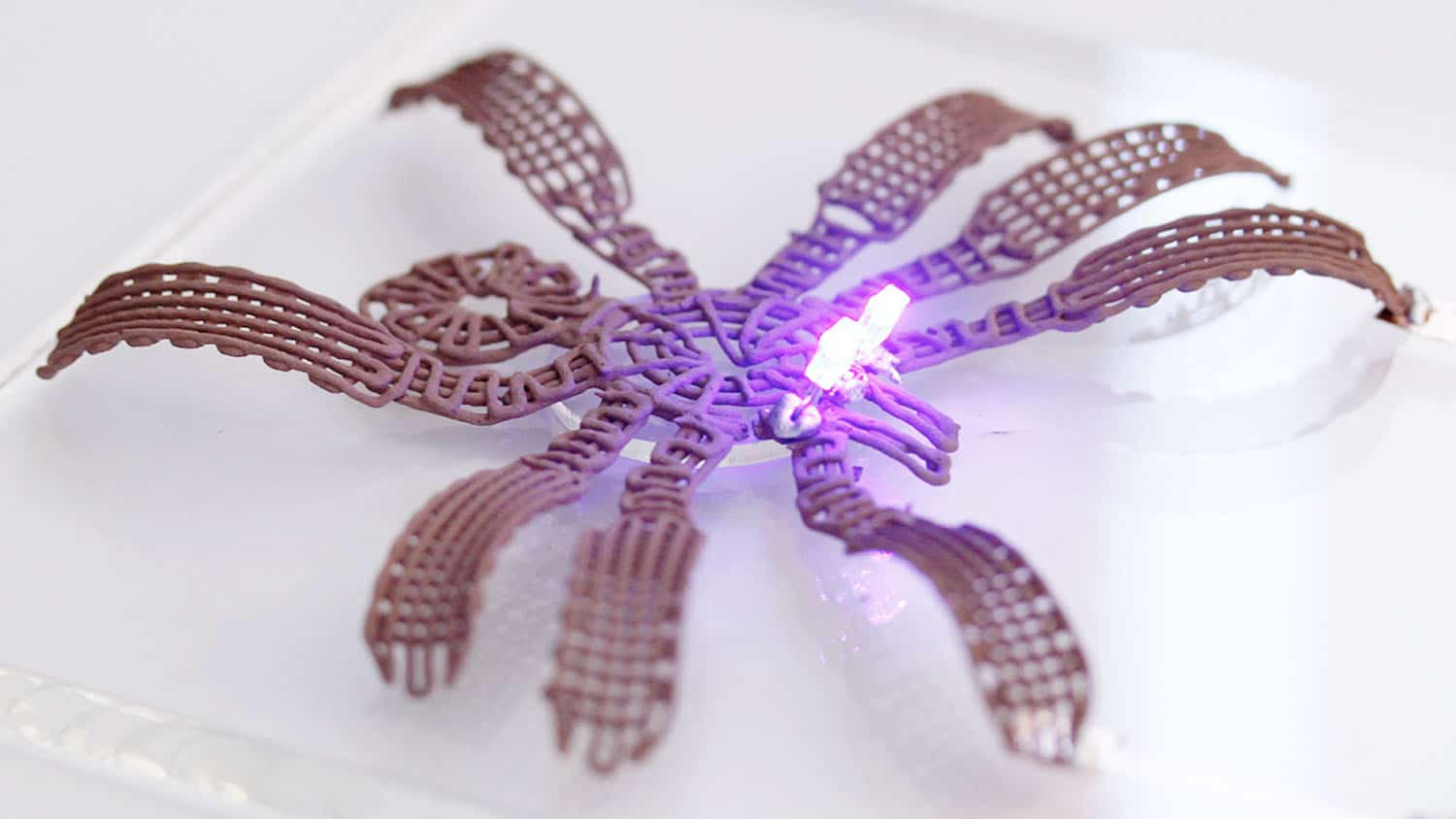

The ensuing gel may be printed utilizing a traditional 3D printing nozzle and maintains its form upon printing. Because it dries at room temperature, the item turns into extra strong whereas retaining its kind. Making use of warmth through the drying course of causes predictable structural adjustments based mostly on the alignment of particles. By controlling the sample of the printed object and the quantity of warmth utilized, it’s doable to change the form of the item after printing.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to enroll in our weekly additive manufacturing e-newsletter to get all the newest tales delivered proper to your inbox.