Our engineering staff not too long ago reviewed the Flashforge Guider 3 Plus. Based mostly in China, Flashforge was based in 2011 and has since constructed up a worldwide distributor community. This evaluate of the Guider 3 Plus, covers their skilled grade FFF 3D printer launched in October 2022 that comes with a CoreXY axis system for high-speed, high-quality printing.

Goal marketplace for the Guider 3 Plus 3D printer

The Guider 3 Plus is focused in the direction of skilled, industrial scale functions. Flashforge advertises the machine as being “the professionals first selection,” highlighting small companies, studios, universities, and laboratories as the important thing buyer bases.

The 3D printer is particularly properly suited to prototyping large-scale fashions and engineering components. Flashforge factors to architectural components, product growth verification, jigs, fixtures, and meeting line components as key use areas.

Unboxing and package contents

The 3D printer was very properly packaged, arriving in excellent situation. The package deal additionally contained quite a lot of equipment, together with 1kg of PLA, heat-resistant gloves, instruments for printer upkeep, a USB stick, a leveling card, and a printbed scraper.

The inner packaging and package contents of the Guider 3 Plus. Photographs by 3D Printing Trade.

{Hardware}

The Guider 3 has a full steel chassis and is a completely enclosed machine. This enables for the 3D printing of advanced supplies that require particular construct environments and temperatures.

The 3D printer’s CoreXY structure is vital, enabling extra inflexible, correct, and quicker outcomes than a conventional cartesian system. Two stepper motors management the X and Y axes, whereas the Z-axis manages the mattress through two giant ball screws and 4 steerage rails. This retains the mattress degree and ensures correct motion.

The 3D printer can even match by means of an ordinary door body, making it properly suited to small companies with restricted area. The 3D printer additionally consists of legs and wheels, optimized for maneuverability round a manufacturing unit ground.

The hotend comes outfitted with many aftermarket components, similar to a leveling sensor and 4 followers stationed across the nozzle to cut back warmth creep and funnel air beneath the nozzle to assist with overhang printing.

The Guider 3 Plus extruder. Photograph by 3D Printing Trade.

The Guider 3 Plus incorporates a heated print mattress able to reaching temperatures of as much as 120 °C. The print mattress presents quick heating occasions and fast cooldowns, serving to to preserve energy. The construct plate can also be versatile, permitting for the straightforward detachment of components.

The Guider 3 Plus’s construct plate and print mattress. Photograph by 3D Printing Trade.

A 7-inch full-color multilingual contact display screen is situated on the entrance of the printer. Intuitive and simple to make use of, the placement of the consumer interface makes it handy for industrial configurations.

Software program/Slicer

Flashforge offers its personal slicer software program, FlashPrint 5. The software program presents quite a lot of options, together with dimensional compensation, treelike helps, and mannequin slicing. This is likely one of the most simple and simple to make use of slicers that we’ve got encountered, with just a few buttons and no further settings inside the primary mode.

FlashPrint 5 additionally consists of an “Professional Mode,” which presents extra superior choices, similar to the power to avoid wasting profiles and configurations as soon as the proper profile is discovered.

Benchmarking check

We first 3D printed the check file supplied with the machine. These 3D prints are usually absolutely optimized for the printer, and a failed end result right here would increase critical alarm bells for the standard of the printer. On this case, the 3D print got here out completely.

Subsequent we carried out a 3D Benchy, which was measured and in comparison with the unique mannequin to check the machine’s accuracy. The typical deviation between the measurements and reference was 0.13mm, a strong end result that’s higher than the common rating of 0.15mm from our different Benchy checks.

Bench 3D printed utilizing the Guider 3 Plus. Photograph’s by 3D Printing Trade.

We subsequent carried out a repeatability check of three completely different components (sq., hexagon, and tube shapes), which had been printed a number of occasions, measured, and in comparison with the unique half dimensions. A mean deviation of lower than 0.1mm, and an ordinary deviation below 0.05mm, will be seen as a profitable end result.

Sq. repeatability check items. Photographs by 3D Printing Trade.

The typical deviation for the sq. check items got here in at 0.0789mm, and the usual deviation at 0.0339mm. The size measurements, nonetheless, introduced some clear inaccuracies, with a median deviation of 0.108mm.

Sq. repeatability check knowledge. Pictures by 3D Printing Trade.

The hexagon checks confirmed common deviations of 0.0568mm, and an ordinary deviation of 0.052mm. The size measurements once more highlighted issues, with a median deviation of 0.085mm. This means that the Z-axis is extra correct than the XY-axis, doubtlessly attributable to belt rigidity.

Hexagon repeatability check items and outcomes. Photographs and Pictures by 3D Printing Trade.

The tube components produced a median deviation of 0.0870mm, and an ordinary deviation of 0.0729mm. The typical results of the exterior diameter was 19.958mm, in comparison with the goal diameter of 20mm. This was extra in-keeping with what we anticipate from a CoreXY machine.

Tube repeatability check items and outcomes. Photographs and Pictures by 3D Printing Trade.

We subsequent carried out a bridge check to find out whether or not the machine may deal with 3D prints with out helps. All components printed efficiently, with high quality remaining sturdy till the 40mm size bridge.

Guider 3 Plus bridge check items. Photographs by 3D Printing Trade.

We adopted the bridge check with a tower and width check. Total, the tower half 3D printed very properly, attaining a measurement of 19.99 mm x 20.06 mm x 599 mm. The width check additionally printed with none points, completely assembly the machine’s marketed construct dimensions of 350x350mm.

Guider 3 Plus tower and width check. Photograph by 3D Printing Trade.

We additionally carried out a round trajectory check, assessing the machine’s means to supply components with round sections.

Guider 3 Plus round trajectory check items. Photograph by 3D Printing Trade.

Nevertheless, the Y-axis persistently supplied much less correct outcomes. That is one thing we wouldn’t anticipate from a CoreXY system, and will have been brought on by one of many stepper motors being much less in tune with the opposite.

Round trajectory check outcomes. Pictures by 3D Printing Trade.

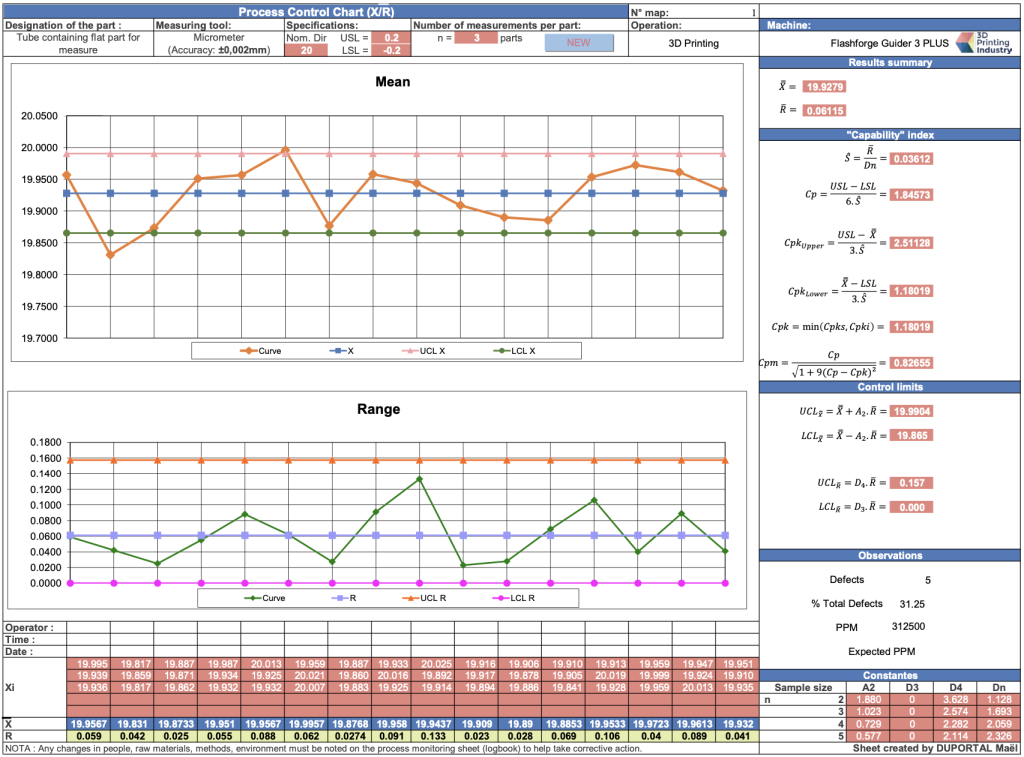

Subsequent, we examined for ‘functionality.’ Right here, the suitability of the machine to supply components inside the tolerance vary talked about within the specs was assessed. We printed the identical mannequin 150 occasions. 16 had been then taken at random, and measured 3 times to calculate their deviations.

Functionality check items. Photographs by 3D Printing Trade.

The Guider 3 Plus achieved a course of functionality (cp) of 1.84 and a minimal course of functionality index (cpk) rating of 1.180. These are good scores, confirming that this machine is each exact and correct.

Utility checks

We first 3D printed an anatomical mannequin to evaluate the machine’s means to print ABS utilizing tree helps. The items printed rapidly and precisely. Nevertheless, the tree helps had been inferior to different programs we’ve got examined.

Anatomical mannequin 3D printed with the Guider 3 Plus. Photographs by 3D Printing Trade.

We then used PA12-CF materials to 3D print each a small utility knife case and a helical gear. Once more, the printer carried out properly, producing good high quality components.

3D printed utility knife case and helical gear. Photographs by 3D Printing Trade.

To check the 3D printer’s functionality of working with excessive warmth tolerances we used PETG to 3D print a fan mount for the Ender 3 v2 printer. The standard right here was spectacular, with no stringing or overhang warping.

PETG fan mount 3D printed with the Guider 3 Plus. Photographs by 3D Printing Trade.

We additionally used PLA to print a planetary gear system, and a prototype mannequin of an engine manifold. The planetary gear mechanism labored completely, indicating excessive print accuracy.

PLA planetary gear system and engine manifold prototype. Photographs by 3D Printing Trade.

We subsequent used Nylon to supply a shelf bracket. Right here, we encountered some adhesion points. Flashforge recommends a printing temperature of 60-70℃, suggesting that our print mattress temperature of 80℃ could have contributed to this failure.

3D printed nylon shelf brackets. Photographs by 3D Printing Trade.

Lastly, we 3D printed Ryno Professional Collection Nasa Cloth, a really intricate mannequin and a superb check of the accuracy of the printer. This half printed properly, regardless of some restricted stringing.

3D printed Reno Professional Collection Nasa Cloth. Photographs by 3D Printing Trade.

Last verdict

Total, we view the Guider 3 Plus as a top quality 3D printer that matches the invoice completely for skilled and industrial customers requiring a big construct quantity.

The 3D printer presents prime quality {hardware}, with a full steel chassis, two giant ball screws, and 4 sturdy steerage rails. The excessive temperature print mattress can warmth as much as 120℃, with the quick heating occasions and fast cooldowns serving to to preserve energy. The construct plate is safely secured by in-built magnets throughout 3D printing, and is versatile for the straightforward removing of components.

The CoreXY structure permits for quick printing speeds of as much as 250mm/s, a 50% improve on the earlier Guider 2 mannequin. This structure additionally ensures that good print high quality is maintained all through the 3D printing course of since there may be much less weight and inertia on the print head, decreasing the consequences of ghosting and ringing brought on by vibration.

The Guider 3 Plus’s substantial Z-axis construct top of 600mm is especially spectacular, marking a big improve on the Guider 3’s 340mm top. Moreover, the 3D printer is suitable with a variety of third celebration engineering grade filaments, with the 320℃ excessive temperature extruder permitting for larger materials freedom.

The 7-inch full-color contact display screen is particularly straightforward to make use of, and the choice of WiFi connectivity is a pleasant contact for these seeking to run this on a community. Furthermore, the addition of inner cameras permits for distant construct monitoring.

All through our utility checks, the 3D printer actually highlighted its versatility, producing good high quality, correct components in a variety of supplies.

Total, with regard to {our capability} testing, the Guider 3 Plus carried out properly and handed most of our checks, with solely a few points encountered with regard to round trajectory and repeatability.

The round trajectory points had been seemingly brought on by stepper motor inaccuracies, nonetheless the machine nonetheless supplied above common outcomes total. Repeatability testing highlighted some Y-plane inaccuracies, however these are rectifiable and sure attributable to both belt rigidity or jolts brought on by the excessive print speeds. {Our capability} check highlighted the excessive accuracy and precision provided by this machine. This means that the Guider 3 Plus is match for goal when 3D printing advanced and detailed components in knowledgeable setting.

The Guider 3 Plus is good for skilled, industrial scale functions, and is optimized to be used on the manufacturing unit ground. For example, the 3D printer’s small footprint makes it excellent to be used in workshops of all sizes whereas nonetheless sustaining a considerable construct quantity. The addition of lockable swivel caster wheels make the printer simply maneuverable, and might hold it firmly situated.

The substantial construct quantity and quick print velocity make it a flexible system nice for industrial prototyping or tooling. Equally, with excessive construct high quality, the Guider 3 Plus is appropriate for producing end-use components.

Finally, this 3D printer has excessive potential within the skilled and industrial markets. We consider that the Guider 3 Plus meets the excessive requirements that we’ve got come to anticipate from Flashforge.

Technical specs

| Structure | CoreXY |

| Construct quantity | 350x350x600mm |

| Max construct velocity | 250mm/s |

| Max nozzle temperature | 320℃ |

| Max mattress temperature | 120℃ |

| Materials compatibility | PLA, ABS, HIPS, PC, TPE, PETG, ASA, PP, Nylon, and Composite/Bolstered |

| third celebration materials suitable | Sure |

| Slicer | FlashPrint 5 |

| HEPA 13 filter | Sure |

| Connectivity | Wi-Fi, Ethernet |

Subscribe to the 3D Printing Trade publication to make sure you sustain with the newest 3D printing information. You may also comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

Featured picture reveals the Flahforge Guider 3 Plus. Photograph by 3D Printing Trade.