ROSS Mixers shares insights on its portfolio and the way the 3D printing sector advantages from its product line.

Since 1842, Charles Ross & Son Firm (ROSS Mixers) has produced industrial mixing, mixing, drying, and dispersion equipment, providing customized and commonplace designs to match various processing wants.

With expertise gained from over 180 years serving the manufacturing world, how can enterprises utilizing 3D printing profit from ROSS methods?

The uncooked supplies, or feedstock, utilized in additive manufacturing play an important position within the 3D printing course of. To provide a high-quality 3D print, the feedstock should even be of constantly high-quality.

Given that almost all feedstock are mixtures and never single-component supplies, mixing and mixing applied sciences play an important position within the additive manufacturing course of.

Power, texture, look, conductivity, sturdiness and different key properties within the completed product are immediately impacted by the blending operation. Deciding on the proper mixing tools is subsequently step one to attaining formulation accuracy and batch-to-batch repeatability.

Within the 3D printing business, ROSS has equipped a lot of tools and mixing options, optimized for the manufacturing of a spread of supplies.

Furthermore, The corporate’s product line serves a variety of functions inside the international chemical, pharmaceutical, meals, plastics, composites, adhesives, coatings, and electronics industries.

ROSS Mixers’ industrial portfolio

ROSS Mixers Tumble Blenders are perfect for the manufacturing of steel and alloy powders utilized in 3D printing. Certainly, Tumble Blenders, out of all of the dry mixing applied sciences, are the most suitable choice for dealing with heavy batches whereas minimizing mechanical put on.

With diffusion as the principle mechanism for mixing, tumble mixing is a low-impact course of, superb for processing abrasive solids and friable elements. This course of can be regularly used when making exact blends containing hint elements or components.

These Tumble Blenders additionally guarantee correct mixing, important for producing excessive purity, chemically homogenous, spherical powders inside a goal particle dimension distribution. This additionally permits glorious move properties and excessive packing density.

One other key advantage of ROSS Mixers Tumble Blenders is their double cone and V cone vessel geometry. This permits for full discharge of the blended materials which interprets to excessive yield, decrease threat of contamination and simple cleansing.

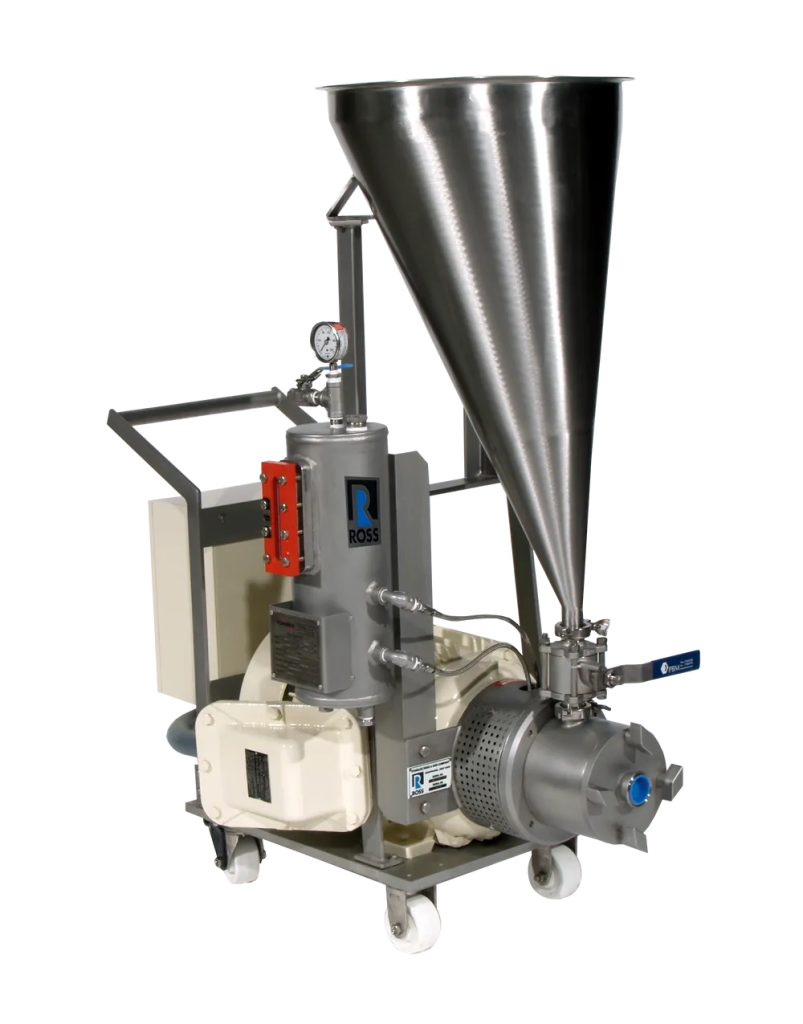

ROSS Mixers Excessive Shear Mixers (HSM) are designed for low-viscosity functions requiring excessive ranges of shear forces and intense turbulence. These mixers are nicely suited to 3D printing functions similar to dispersion of pigments, components and filler into resins or waxes; polymer suspensions, ceramic slurries; lubricants (like silicone emulsions and Teflon suspensions); and binder options.

Excessive Shear Mixers can be found in batch (vertical) or inline (horizontal) configurations, and embrace a rotor that turns at excessive speeds inside a stationary stator. This course of achieves extraordinarily quick mixing, with rotor tip speeds typically reaching speeds between 3,000 and 4,000 ft/min. This breaks down agglomerates and reduces the scale of droplets.

ROSS Mixers additionally supply their SLIM (Solids/Liquid Injection Manifold) Know-how, a key improvement in rotor/stator design. This high-speed powder induction system, that may be added to ROSS Excessive Shear Mixers, creates a vacuum behind the rotor. This vacuum can be utilized to inject powdered (or liquid) elements immediately into the excessive shear zone.

This course of is right for powders that don’t simply combine with liquids. For example, feedstock or intermediate supplies thickened with fumed silica, carboxymethyl cellulose, hydroxyethyl cellulose, carbomer, bentonite clay or xanthan gum typically profit from powder induction through a SLIM system.

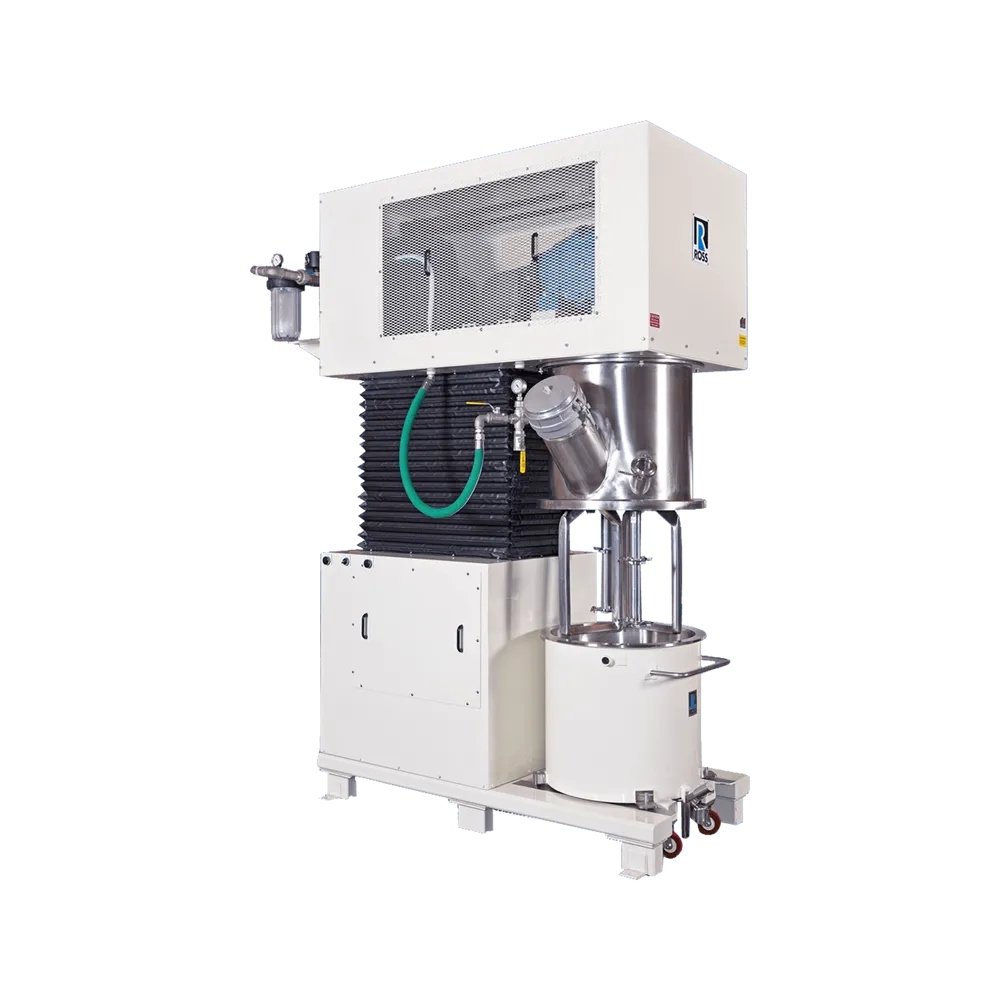

ROSS Mixers Multi Shaft Mixers supply related dispersion, emulsification, and homogenization capabilities as Excessive Shear Mixers. Nevertheless, these machines can flip over viscous supplies, combine beneath vacuum and supply tighter temperature management.

Two fashionable configurations of those machines are the Triple-Shaft Mixer, consisting of a Excessive Shear Mixer, a Excessive-Velocity Disperser and a Three-Wing Anchor, and the cheaper Twin-Shaft Mixer. This configuration consists of a Excessive-Velocity Disperser and a Two-Wing Anchor.

These mixers supply superior viscosity and warmth switch capabilities in comparison with single shaft gadgets. Furthermore, they’re closed methods, providing advantages in vacuum mixing similar to larger density, superior dispersion high quality, higher tensile properties, much less defects and longer stability.

Widespread functions for Multi-Shaft Mixers embrace polyvinyl alcohol options, plastisol and different thermoplastic inks, rubber blends, polyurethane-based composites, bolstered epoxies, and different crammed resins.

ROSS Mixers Twin and Triple Shaft Mixers. Images through ROSS Mixers.

ROSS Mixers additionally supply a spread of Planetary Mixers, superb for the manufacturing of 3D printer feedstock with excessive viscosity.

The ROSS Double Planetary Mixer is right for the manufacturing of 3D printer feedstock with excessive viscosity, and is optimized for viscous formulations as much as 6 million cP or extra.

This providing incorporates two equivalent blades which rotate independently whereas orbiting the mixing vessel on a standard axis. The 2 blades transfer all through each level within the product zone, bodily contacting your entire batch in solely 36 revolutions all through the vessel.

As a result of the blades of those machines run at comparatively low speeds, these mixers can tolerate abrasive functions, together with steel or ceramic dispersions in polymer, wax or resin binding brokers. Equally, shear-sensitive supplies, similar to hydrogels and syntactic foams, are extensively produced in Double Planetary Mixers.

The ROSS PowerMix is a hybrid planetary disperser combining excessive and low velocity agitation for mixtures that begin out very fluid and thicken up all through the batching course of.

From water-like viscosity to round 2 million cP, the PowerMix can impart excessive shear at any stage. Furthermore, each agitators are independently managed. This permits move patterns and shear charges to be finely tuned because the product undergoes adjustments all through the blending cycle.

ROSS Mixers additionally supply a four-shaft design, with their Planetary Twin Disperser (PDDM). This sturdy system combines two planetary blades with two high-speed dispersion blades. This permits strong additions to be produced in bigger portions and shorter intervals. Agglomerates disintegrate quicker, and turnover is extraordinarily environment friendly even when the fabric is especially dense or sticky.

ROSS Mixers Interfacial Floor Generator (ISG) Static Mixers are particularly nicely suited to injection molding and extrusion functions. Certainly, ROSS claims that the ISG Static Mixer is without doubt one of the most broadly used static mixer fashions in injection molding and extrusion functions.

Using static mixing has been proven to boost the standard of injection molded and extruded merchandise. The molten materials is injected via a collection of static mixer parts fitted earlier than the die meeting contained in the nozzle. The static mixer can rectify a number of discrepancies within the extruded stream inside a really transient size of pipe.

Thermal homogenization, constant density and density, improved mixing of colours and minimal components, efficient utilization of all uncooked supplies, eradication of streaks or clouds within the ultimate product, top quality, and yield are simply among the advantages.

ISG Static Mixer components. Images and Pictures through ROSS Mixers.

ROSS Vertical Mixers for drying and mixing plastic resins and nylon pellets

Plastic resins soak up moisture from the encircling surroundings. Water accumulates on the floor, and if the plastic is hygroscopic, contained in the polymer. Drying is essential as a result of extra moisture within the preliminary resin materials could cause decrease energy, visible defects, and poor efficiency of the completed half.

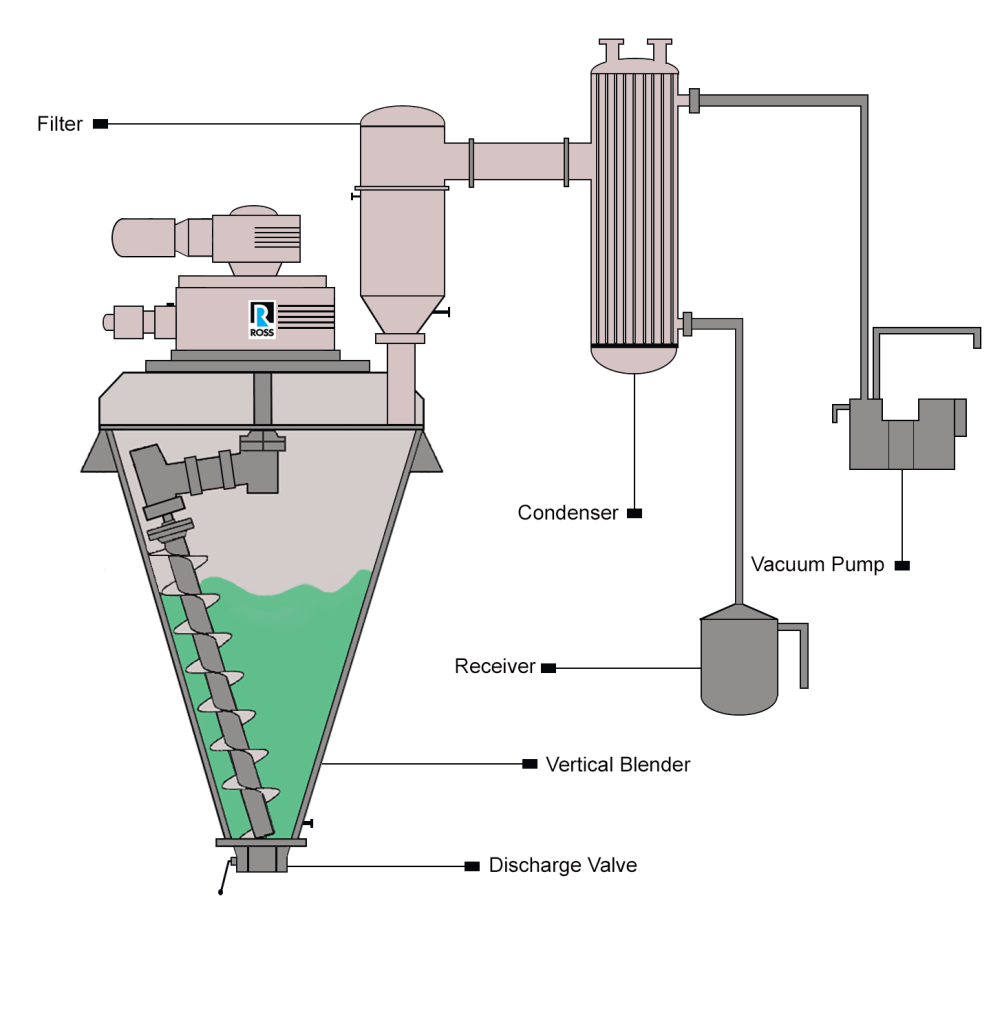

ROSS Mixers Vertical Blender/Dryers with vacuum functionality are “well-proven” drying tools for plastic resins. Vacuum drying is an efficient method for manufacturing heat-sensitive plastics with out worrying about thermal degradation as a result of it requires comparatively low temperatures to drive off moisture.

As soon as the vacuum is established, the combination of low absolute stress, light warmth, and gradual agitation quickly drive moisture from the majority materials. Vapors produced throughout the course of are filtered and condensed. If relevant, a receiver gathers the condensed liquid for protected disposal or reuse.

Nylon pellets are regularly combined with different plastics, coated with lubricant powder, or mixed with intensive pigments and different components.

In some circumstances, lowering the moisture content material of the pellets is required to keep away from deficiencies within the ultimate product and course of discrepancies. Over-drying can hurt the move conduct of nylon pellets, so drying to a super degree is essential. The adaptable Vertical Blender is distinctively fitted to attaining the entire above objectives.

Ross Vertical Blenders may mix nylon pellets with different strong components or polymers of nearly any form and dimension. Vertical Blenders use the identical course of on nylon pellets as plastic resins.

ROSS Double Planetary Mixers mixing tools for dental composites

Dental composites are bolstered with glass and ceramic particles. Double Planetary Mixers are time-tested instruments for making ready dental composites.

Newer helical blade designs present higher mixing and extra simple managing of viscosity peaks as excessive as 6 million centipoises. Ross Excessive Viscosity “HV” Blades (US Patent No. 6,652,137) are the “first of their form,” with an precisely angled contour that produces a selected mixing motion.

Ross Double Planetary Mixers are used for abrasive supplies worldwide and are usually hard-chrome plated or coated with Kynar (polyvinylidene fluoride) or aluminum oxide. The paste turns into discolored when abrasive composites are combined in a conventional stainless-steel mixer (stainless-steel particles are built-in into the formulation).

Even minor contamination is unacceptable in dental composites, the place correct optical properties are essential.

To study extra about this know-how report, or to request a quote, fill out ROSS Mixers’ request type.

Subscribe to the 3D Printing Trade publication to maintain updated with the newest 3D printing information. You can even observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a number of out there roles and kickstart your profession.

Featured picture reveals ROSS Mixers’ industrial mixing, mixing, drying, and dispersion equipment. Picture through ROSS MIxers.