Scientists from Edinburgh’s Heriot-Watt College have developed a brand new methodology that makes use of near-infrared (NIR) mild to 3D print advanced constructions with a number of supplies and colours. Dr. Jose Marques-Hueso led the analysis from Heriot-Watt’s Institute of Sensors, Indicators & Programs.

The staff modified the widely-used stereolithography (SLA) 3D printing course of to attain higher multi-material integration.

Conventional SLA 3D printing applies a blue or UV laser to a liquid resin, which is selectively solidified layer by layer. Nonetheless, this course of lacks materials intermixing capabilities. By way of this new course of, the scientists employed a NIR mild supply able to 3D printing into the resin vat at higher depths. The scientists declare that this novel course of gives important potential for 3D printing specialist components, notably throughout the well being and electronics sectors.

This isn’t the primary 3D printing course of to allow multi-material 3D printing. Certainly, Fused Deposition Deposition (FDM) has lengthy provided capabilities for 3D printing with a number of supplies. Nonetheless, the scientists declare that their new methodology permits for producing multi-material components at a lot greater resolutions.

In accordance with Dr. Adilet Zhakeyev, a Ph.D. researcher at Heriot-Watt College who has labored on the challenge for practically three years, “Fused Deposition Modelling (FDM) know-how was already in a position to intermix supplies, however FDM has a low decision, the place the layers are seen, whereas light-based applied sciences, resembling stereolithography, can present easy samples with resolutions below 5 micrometers.”

The challenge, titled ‘Multimaterial Stereolithography by Crosslinking by means of Luminescence Excitation,’ has obtained £280,000 in funding from the Engineering and Bodily Sciences Analysis Council (EPSRC). The staff’s findings have been printed within the journal Utilized Supplies At this time.

The brand new NIR 3D printing course of

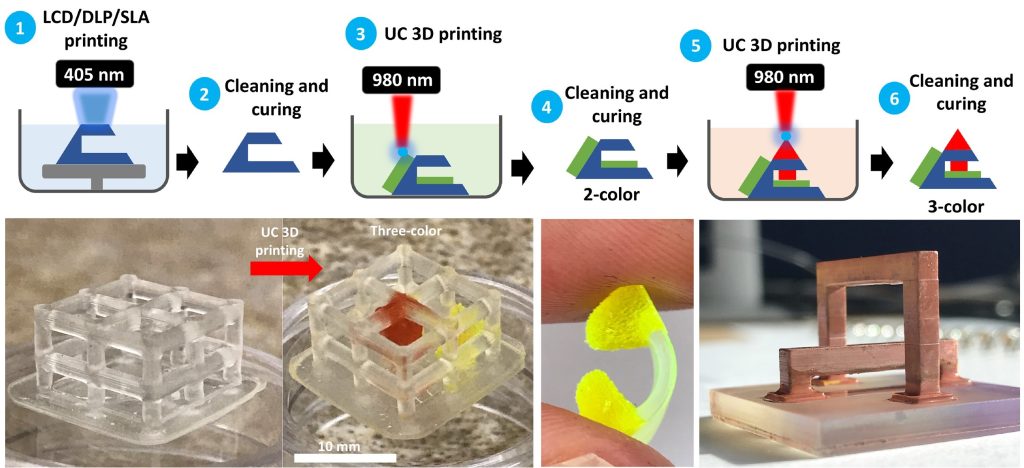

New to this methodology is the usage of NIR invisibility home windows of supplies to 3D print at depths of over 5 cm, a considerable improve from standard SLA know-how’s 0.1mm depth restrict. Dr. Marques-Hueso claims that this methodology “has by no means been completed earlier than.”

A key advantage of this new course of is that it permits customers to 3D print an element in a single materials, including a second materials afterward. This second materials shouldn’t be restricted to the highest and outer surfaces of the 3D printed half and might be solidified at any place within the 3D house. It is because the NIR laser can penetrate by means of the outer layer of the preliminary half.

“For instance, we will print a hole dice that’s largely sealed on all sides. We will then come again later and print an object created from a completely completely different materials inside this field as a result of the NIR laser will penetrate by means of the earlier materials as if it have been invisible as a result of actually, it’s fully clear on the NIR,” defined Dr. Marques-Hueso.

In accordance with the researchers, a key element of this challenge has been the event of engineered resins containing nanoparticles that exhibit optical upconversion. These nanoparticles take up the NIR photons, remodeling them into blue photons, which solidify the resin.

This phenomenon is ‘non-linear’, which means that it could actually receive the blue photons largely on the laser’s focus and never on the best way by means of it. This permits the NIR to penetrate deep into the fabric as if it have been clear, solely solidifying the inside materials.

In the end, this new course of permits a number of supplies with completely different properties to be 3D printed in the identical pattern. For example, versatile elastomers and inflexible acrylic might be 3D printed collectively. The scientists level to varied purposes that this methodology advantages, together with 3D printing inside cavities, shoe manufacturing, restoration of damaged objects, and in-situ bioprinting by means of pores and skin.

This course of can also be notable for its affordability. “A transparent benefit of this system is that the total machine might be constructed for lower than £400. Another superior applied sciences that use lasers, resembling Two-Photon Polymerisation (2PP), require costly ultrafast lasers within the order of tens of 1000’s of kilos, however this isn’t our case as a result of our specialist supplies enable the usage of cheap lasers,” stated Dr Marques-Hueso.

“Now that we’ve outcomes to help our claims, we hope to accomplice with companies and develop this know-how additional,” added Dr Marques-Hueso.

Multi-material resin 3D printing

The Heriot-Watt strategy shouldn’t be the primary course of to allow multi-material resin 3D printing. Final yr, Barcelona-based 3D printer producer BCN3D unveiled a brand new Viscous Lithography Manufacturing (VLM) 3D printing know-how. Researched and developed over three years, this know-how gives dual-material resin 3D printing capabilities, permitting customers to 3D print two completely different resins in a single construct.

BCN3D’s multi-material resin providing makes use of a UV mild engine and LCD display. In contrast to most LCD 3D printers, this technique leverages a particular mechanical system that laminates resin onto a movie. This movie is transported to the construct space the place the resin is cured, transferring from the movie to the half on the construct plate. As a result of the VLM resins might be laminated and cured on two completely different movies, it’s potential to mix two resins for multi-material components and soluble help constructions.

Final yr, Dr. Adrian Bowyer, the founding father of RepRap, proposed a brand new methodology for SLA multi-material 3D printing. Bowyer’s methodology consists of 3D printing the primary layer in resin A, which is then poured away. Resin B is then added to 3D print the primary layer once more. Subsequent, the second layer is 3D printed with resin B. This resin is then poured away, and the layer 3D printed once more in resin A. By repeating this course of, Bowyer claims that every layer may very well be 3D printed with two completely different supplies.

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the most recent 3D printing information. You can even observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a choice of accessible roles and kickstart your profession.

Featured picture exhibits Dr Jose Marques-Hueso. Picture by way of Hariot-Watt College.