Edinburgh-based non-public rocket producer Skyrora has begun full-duration testing to qualify the up to date design of its 3D printed 70kN rocket engine. Skyrora’s Skyprint 2 3D printers have been used to 3D print the brand new rocket engines, reportedly reducing manufacturing occasions by 66% and prices by 20%.

Set for use for the corporate’s first industrial orbital launch, the brand new engine design options an improved cooling chamber. It will optimize cooling effectivity, extending the engine’s life cycle.

As soon as efficiently accomplished, the testing will mark a key milestone in Skyrora’s contract underneath the European House Company (ESA)’s Business House Transportation Companies and Help Programme, also called Enhance!

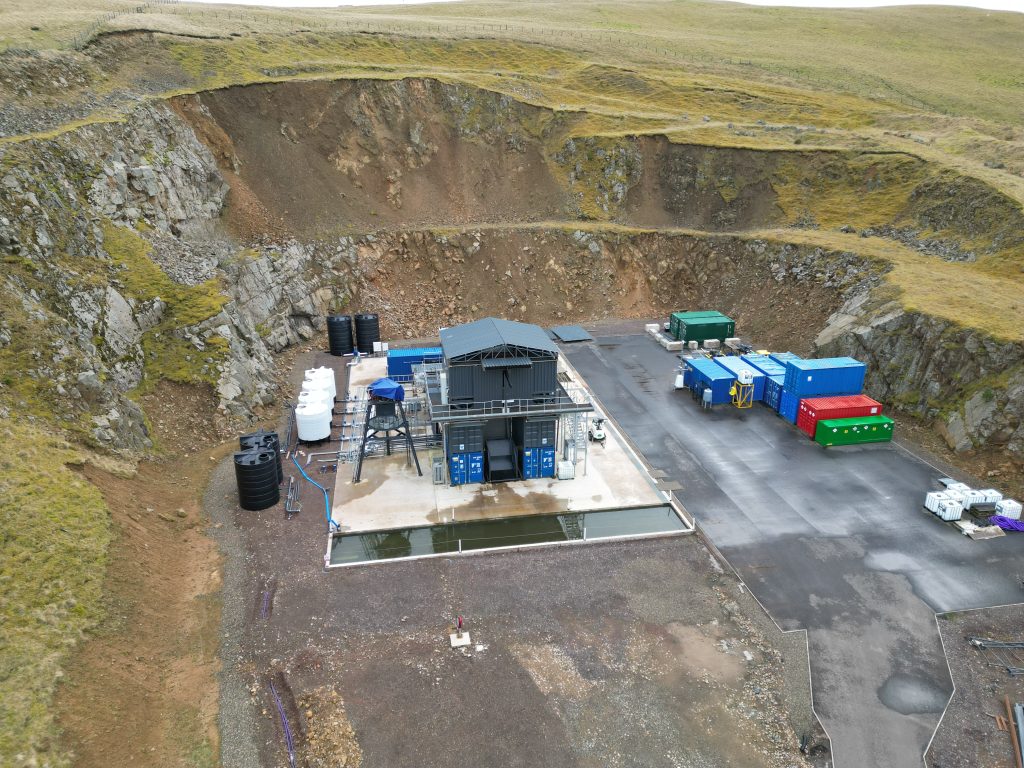

Testing is going down at Skyrora’s Midlothian check web site, the biggest of its type within the UK, and can proceed to be overseen by the corporate’s crew of specialists all through the summer time. Skyrora’s mission performs a key position in ongoing efforts to re-shore business within the UK and Europe, securing provide chains and rising the UK area sector.

“With our purpose-built rocket manufacturing and testing amenities in Scotland, we’re proud to be localizing as a lot of the launch worth chain as doable,” commented Skyrora CEO and Founder Volodymyr Levykin. “The brand new engine know-how developed by Skyrora’s engineers and the dedication to a sustainable design are a testomony to the innovation going down within the UK area sector.”

Testing Skyrora’s up to date 70kN rocket engine

The engine checks will run for 250 seconds every, the identical period of an actual mission to orbit. Varied parameters, together with life cycle and full operational envelope assessments, will likely be evaluated through the engine testing course of.

Taking roughly three weeks to finish, a full check article iteration consists of knowledge evaluation, design changes, and manufacturing. Finally, a profitable check will likely be indicated by nominal chamber stress and thrust ranges with no broken {hardware}.

As soon as absolutely examined and certified, the up to date 70kN will turn into the primary industrial rocket engine to make use of a closed-cycle combustion system run on a propellant mixture of Hydrogen Peroxide and Kerosene. Traditionally, such engines haven’t been used as a consequence of their complexity. Nonetheless, the upper particular impulse generated by Skyrora’s design is alleged to considerably improve the general effectivity of the engine.

Skyrora’s Head of Engineering, Dr Jack James Marlow, said that “We’re coming very near finalizing our engine qualification programme after a protracted journey of technical progress, which will likely be a large success for the crew.”

“It is a key milestone which can qualify one of many most important subsystems of our orbital launch automobile to the right requirements for industrial operations, and as such, is a major step within the journey to orbital launch,” continued Marlow.

Scaling and commercializing UK-based area flight

“The brand new fashions of 3D printed engines are bringing Skyrora nearer in direction of environment friendly industrial orbital launch,” claims Levykin.

Certainly, with extra help from ESA’s Enhance! programme, the up to date engine design will act as a important part on the primary and second levels of Skyrora’s XL orbital automobile.

Skyrora can even collaborate with the Nationwide Manufacturing Institute of Scotland (NIMIS) to qualify the machine, supplies, and technique of machining for Skyprint 2. These {qualifications} will permit Skyprint 2 for use by third events commercially, diversifying the corporate’s providing inside a brand new area market.

“Skyrora is making vital progress in direction of the 70kN engine qualification, which is among the key aims of the pre-commercial launch service improvement actions supported by ESA’s Enhance! Programme,” commented Jorgen Bru, Business Companies Supervisor on the European House Company. “ESA is continuous to help Skyrora alongside the way in which to supply new industrial launch companies for the advantage of a aggressive area sector in Europe.”

Skyrora claims that, as soon as certified, it will likely be in a position to scale up manufacturing. As soon as the engine qualification programme is accomplished, the corporate plans to fabricate a sequence of manufacturing engines to check the complete first stage of Skyrora XL.

That is the ultimate testing stage previous to a demo orbital launch. This full stage check will comply with the profitable testing of the third and second levels of Skyrora XL in 2020 and 2022 respectively. Final 12 months’s second stage check was the biggest of its type to be carried out within the UK for the reason that Nineteen Seventies.

Along with engine qualification, Skyrora has been working intently with the UK Civil Aviation Authority (CAA) to progress their orbital launch automobile license software, which was submitted final 12 months. As soon as authorized, the license will permit Skyrora to start industrial launch operations from SaxaVord Spaceport within the Shetland Isles.

3D printed area rockets

The usage of additive manufacturing for the manufacturing of area rockets is nothing new. Earlier this 12 months, Australian warmth switch specialist Conflux Expertise partnered with German area rocket producer Rocket Manufacturing facility Augsburg (RFA) to embed their 3D printed warmth exchanger into an orbital rocket.

A part of the Australian House Company’s Moon to Mars initiative, the warmth exchanger parts are 3D printed utilizing Conflux Expertise’s Monel Ok 500 metallic alloy materials and EOS M300-4 Direct Steel Laser Sintering (DMLS) 3D printers.

Elsewhere, in April Relativity House launched the world’s first 3D printed rocket, the Terran 1, marking a major step ahead for additive manufacturing’s position inside the area business. After launching from Cape Canaveral House Pressure Station in Florida the rocket, 85% of which is 3D printed, in the end failed to achieve orbit. But, the Terran 1 launch was heralded as successful by Relative House, which intends to extend the 3D printed mass of future automobiles to 95%.

Subscribe to the 3D Printing Trade publication to make sure you sustain with the newest 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

Featured picture reveals the Skyrora 70kN rocket engine in motion. Photograph by way of Skyrora.