A current paper from Graz College of Know-how has unveiled a method of 3D printing with supercooled liquids, which might significantly improve the pace of additive manufacturing. The analysis focuses on one materials specifically, sodium acetate trihydrate, which is a salt hydrate.

Salt hydrates exhibit distinctive properties when subjected to supercooling, which is the method of decreasing the temperature of a liquid beneath its freezing level, with out it turning into a stable. Sodium acetate trihydrate was most well-liked over different salt hydrates as it’s simply out there, and displays low poisonous conduct in comparison with different salt hydrates.

Supercooled liquid salt hydrates can quickly crystallize, doubtlessly permitting for considerably sooner printing speeds, presenting an thrilling alternative to reinforce the effectivity of 3D printing processes.

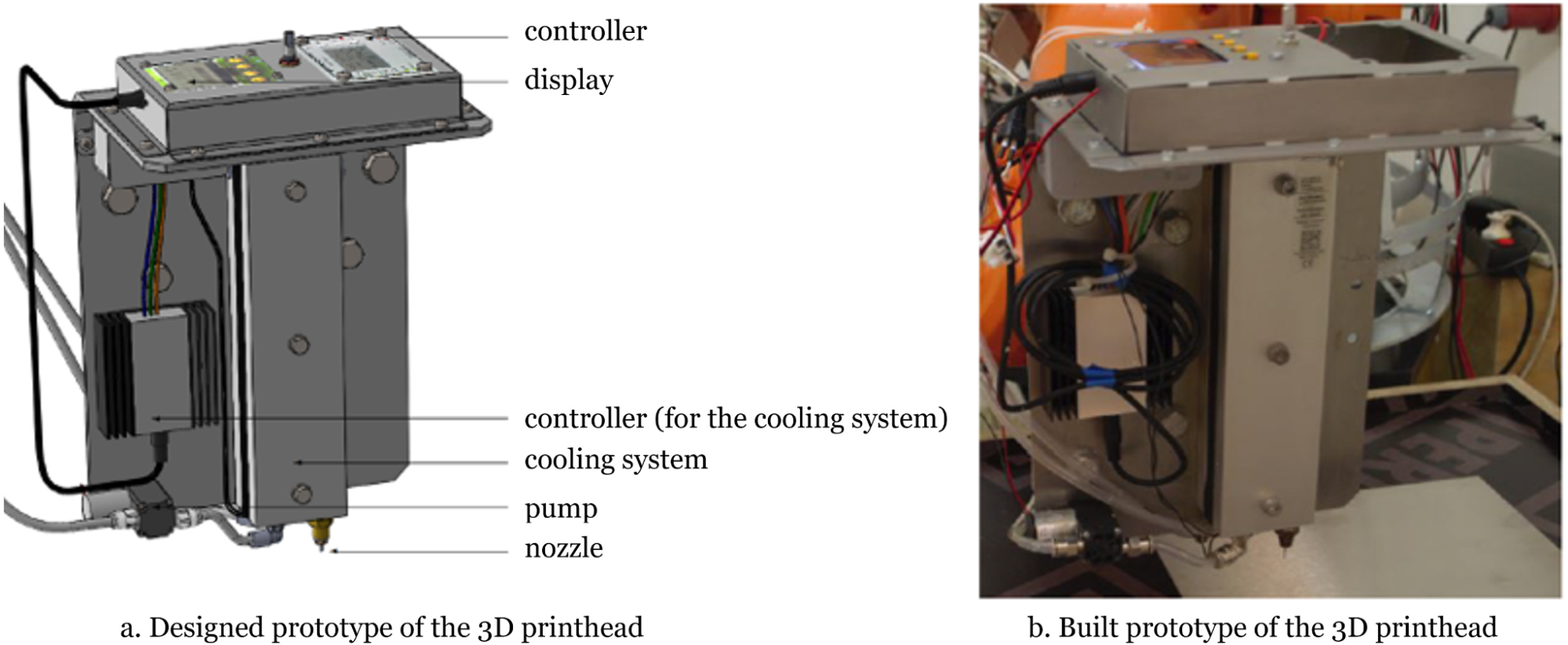

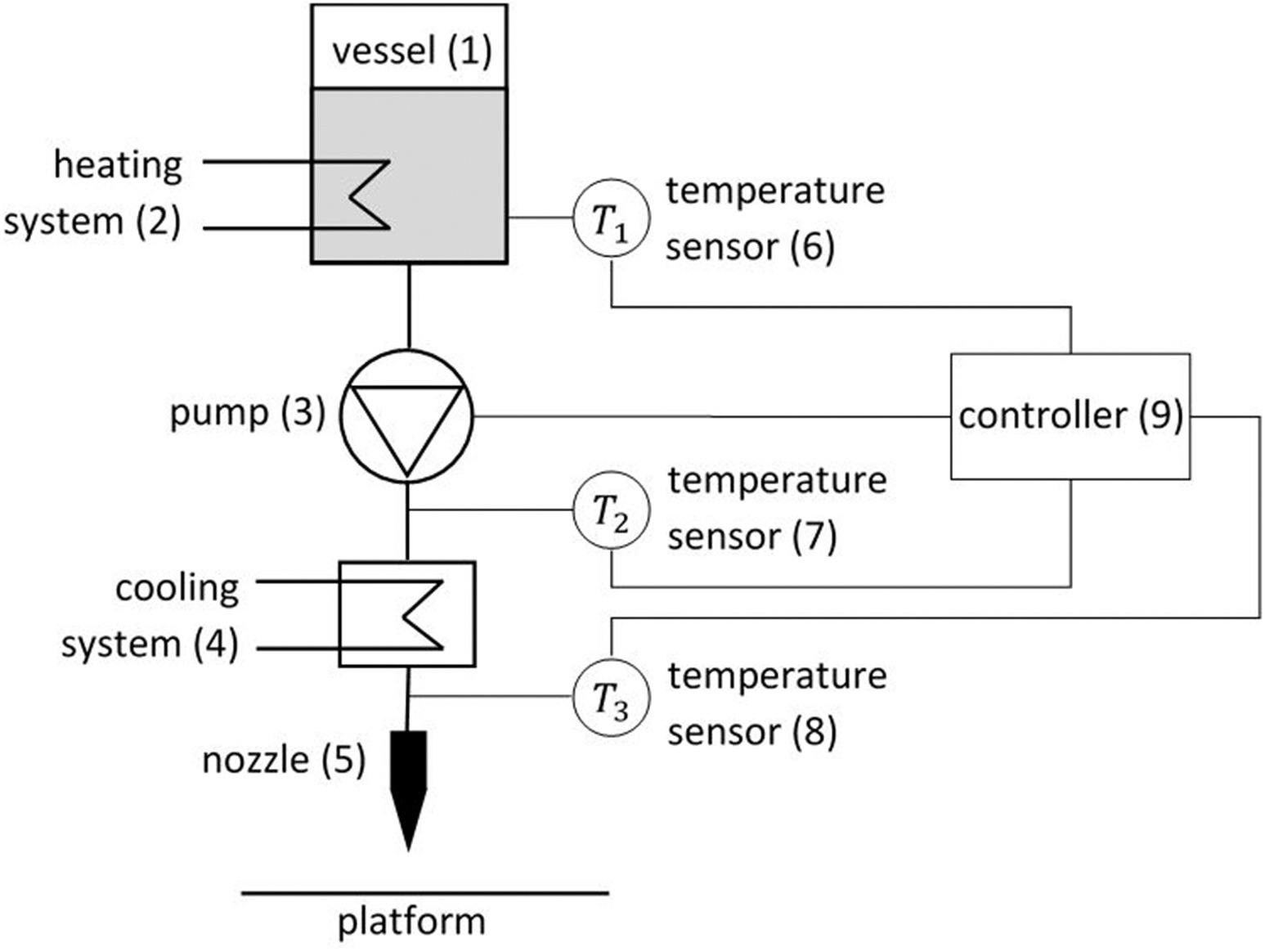

To validate the theoretical framework, experiments had been performed utilizing a robot-mounted printhead designed for printing sodium acetate trihydrate. Materials properties, akin to density, floor stress, and viscosity, had been fastidiously thought of within the experiments. The outcomes indicated a robust correlation between theoretical predictions and sensible outcomes. The experiments showcased the power to manage the geometry of the deposited layers.

As talked about beforehand, one of the crucial thrilling points of 3D printing with supercooled liquids is its potential for elevated printing pace. The analysis paper highlighted that this methodology might obtain nozzle exit velocities of as much as 6.4 m/s, translating to printing speeds of a hefty 53 kg/h. This benefit positions supercooled liquid deposition as a compelling different to conventional 3D printing processes, significantly for purposes requiring fast manufacturing.

The power to manage geometry shapes in the course of the printing course of and some great benefits of water-soluble salt hydrates make this system promising for a number of purposes, together with artwork, restoration, and mildew manufacturing.

The researcher (Markus Brillinger) has concluded the paper by acknowledging ongoing analysis efforts to additional refine and industrialize the method, addressing challenges associated to course of management and stopping back-crystallization. As well as, Brillinger can be investigating different salt hydrates, together with aluminum potassium sulfate dodecahydrate, and magnesium chloride hexahydrate.

You may entry the pre-proof paper, titled “3D printing of supercooled liquids: Modeling and verification on sodium acetate trihydrate” within the Additive Manufacturing journal, at this hyperlink.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to enroll in our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.