A primary-of-its-kind undertaking below development at a 51-year-old Coca-Cola bottling facility in Elmsford, New York, is notable each for the way it will enhance the positioning’s power reliability and the way it will seize carbon dioxide throughout manufacturing to carbonate drinks together with Sprite, Coke and Fanta made there.

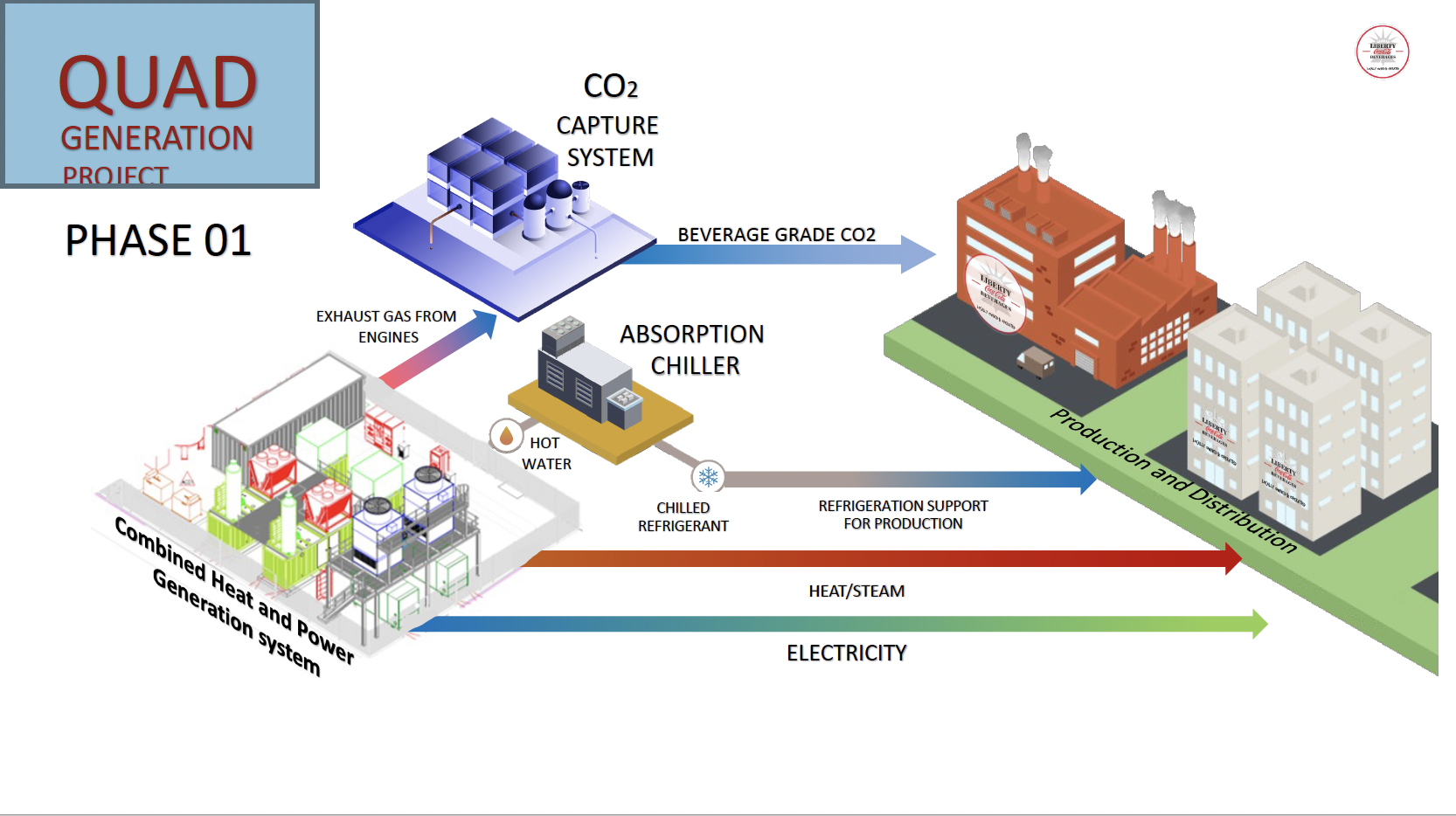

The “quadgeneration” system being put in by Clarke Power (a division of Kohler Co.) will allow Liberty Coca-Cola Drinks’ 21.5-acre website to generate its personal electrical energy, whereas additionally powering heating and cooling processes similar to creating steam for sanitation and chilling drinks earlier than they’re bottled. It can additionally assist a brand new system that may let Liberty use self-recovered carbon dioxide to carbonate its drinks relatively than trucking the fuel in from elsewhere.

How the system works

On the coronary heart of the set up, scheduled to be up and dealing in December, are two Jenbacher reciprocating engines fed by an current fuel pipeline that serves the positioning. This isn’t a small-scale operation: It produces roughly 41 million circumstances of drinks yearly distributed to eating places, retailers and supermarkets in 5 states together with New Jersey, New York and Pennsylvania. The corporate is the biggest family-owned producer and distributor for Coca-Cola within the Northeast U.S.

A rising variety of industrial websites are utilizing cogeneration techniques to concurrently produce electrical energy and warmth power. Analysis agency Guidehouse Insights estimates the worldwide market at about $20 billion in 2023, with the capability of those techniques rising at a compound annual progress price of about 5 % between 2019 and 2028.

Quadgeneration applied sciences — which add carbon seize options to the power era processes — are commonest in greenhouses, the place the CO2 is used to encourage plant progress, stated Guidehouse Senior Analysis Analyst Peter Marrin. “Nevertheless, one other promising market is the meals and beverage business, the place CO2 is the most typical compressed fuel used,” he stated.

However the kind of software being put in by Liberty continues to be comparatively distinctive, in line with Liberty and Clarke: Whereas related tools is operational in Europe and Africa, it’s the primary time the expertise is being deployed in North America.

“This complicated expertise will considerably cut back Liberty’s carbon emissions by high-efficiency native power manufacturing,” stated Clarke Power CEO Jamie Clarke in an announcement. “With the advantages of the current Inflation Discount Act and elevated worth of CO2 globally, this offers many alternatives for carbon seize applied sciences in america.”

Whereas Liberty’s co-owner, Paul Mulligan, declined to reveal the price of the undertaking, he stated total the funding ought to pay for itself inside 3.5 years and the corporate was in a position to faucet tax incentives made doable by the Inflation Discount Act. Trying forward, the set up will assist the power guarantee a extra dependable supply of energy because the New York grid combine transitions to renewable sources. Finally, the system will present an estimated 1.7 megawatts of electrical energy, sufficient to cowl the positioning’s whole energy demand. From an emissions discount standpoint, it would eradicate about 200 deliveries of carbon dioxide at the moment delivered to the positioning every year by way of truck.

How Liberty bought the concept

Many components impressed this undertaking, which took virtually three years to tug off from planning to commissioning — together with sporadic blackouts which have turn out to be extra widespread in New York state. “This undertaking was accepted as a result of it took us off the grid,” stated Dylan Penn, senior supervisor of operations engineering for Liberty.

The corporate’s manufacturing group realized early that it was fixing for 2 associated issues — the necessity to cut back atmospheric CO2 whereas concurrently making certain an enough provide of CO2 purified to food-grade requirements. Carbon dioxide is essentially the most generally used fuel within the meals and beverage sector, and the U.S. business confronted shortages throughout 2022 that impressed extra corporations to assume in another way.

The corporate thought-about many choices as a part of the request for proposals, together with hydrogen gas cells. The power’s current fuel line and the potential to improve the engines to various gas sources sooner or later had been components within the choice, Penn stated.

One other massive consideration was whether or not integrating the engines would disrupt the prevailing bottling traces, however Penn stated Liberty wasn’t compelled to relocate current tools. The largest change in retailer is the method by which the captured CO2 will probably be purified and saved in tanks that may accommodate a roughly seven- to 10-day provide.

Other than the technical evaluations, Liberty spent months working with native officers to earn the approvals — a number of boards reviewed and accepted variances for the towers to soak up the CO2 in addition to total modifications to the positioning so as to add the brand new engines. These talks are ongoing as Liberty strikes nearer to flipping the system on by January. That’s vital for any firm contemplating the same possibility, Penn stated. “We dwell in our yard. We’re neighbors of our neighbors that dwell with the affect of this exercise.”

That is a part of broader sustainability efforts

Improvements by its bottlers are integral to Coca-Cola’s 5-year-old World With out Waste technique, which incorporates targets for making 100% of the corporate’s packaging recyclable by 2025, working towards a one-for-one assortment system for Coca-Cola cans and bottles, and collaborating with prospects, governments and different organizations to get the job accomplished.

Liberty participates in Coca-Cola bottler gatherings to share greatest practices towards assembly these targets, and its quadgeneration guess is charting a brand new course, in line with Mulligan.

To this point, he stated the corporate has invested greater than $60 million in its company sustainability efforts. For instance, Liberty was the primary U.S. soft-drink producer to change the plastic rings that maintain multipacks of cans along with a paperboard various referred to as the KeelClip; it transitioned to clear bottles from inexperienced with a view to enhance recycling; and it invested in XCycler techniques to compress damaged and broken merchandise — what as soon as took 22 truckloads to take away from its crops now takes only one. Liberty final 12 months inked a take care of renewable pure fuel firm Clear Power Fuels that covers about 250 vans in New York and Philadelphia. The transfer will cut back emissions by about 300 % in contrast with diesel, in line with the businesses.

“Should you actually authentically care, you’ll do the appropriate factor,” Mulligan stated.