Researchers from the College of Tokyo have unveiled a brand new technique combining 2D printing, origami, and chemistry to realize fast 3D object fabrication with out producing any materials waste.

Referred to as 4D printing, this technique introduces a definite 3D manufacturing strategy, with the potential to beat limitations and open intriguing prospects for various industries. In contrast to standard layer-by-layer 3D printing methods that result in prolonged manufacturing occasions and materials waste, the researchers drew inspiration from 4D printing. Right here, supplies with distinctive properties self-fold into complicated 3D shapes underneath particular circumstances, leveraging time as a vital side within the transformation.

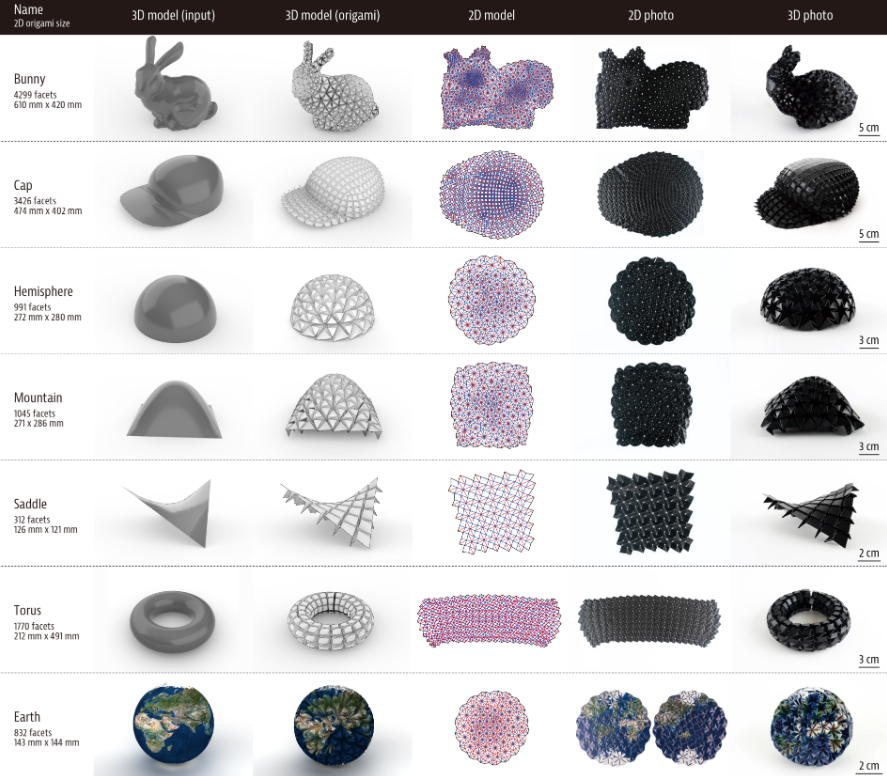

“Our largest problem was refining the choices for {hardware} and supplies, which took over a yr to slender it right down to the ultimate selections,” stated Koya Narumi, Mission Assistant Professor, Division of Electrical Engineering and Data Techniques on the College of Tokyo. “However all of the trial and error was price it; in comparison with earlier analysis round this identical primary concept, we’ve improved the output decision by 1,200 occasions, which means the designs we are able to create usually are not simply novelties, however can be utilized for actual functions. Sooner or later, we could discover useful supplies, equivalent to conductive or magnetic inks, that might permit for machines and different useful gadgets.”

A brand new technique for fast and waste-free fabrication

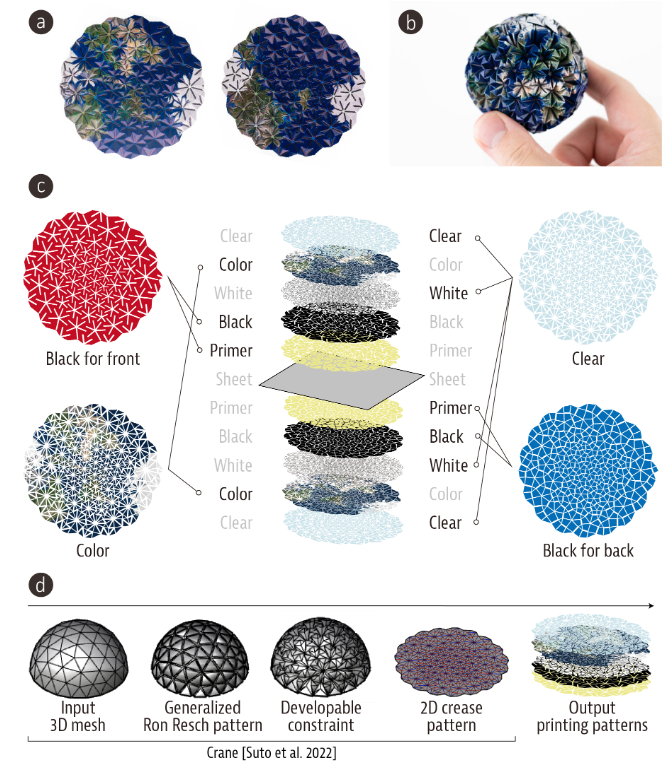

On the core of the approach lies a specialised inkjet printer engineered to deal with UV-reactive supplies. Though these printers could entail a better value, they’re readily accessible in maker communities and shared workshops. The printer applies a 2D origami design with precision to each side of a heat-shrinking plastic sheet. Moreover, the ink used within the printing course of stays unaffected throughout subsequent shrinking, making certain it retains its flexibility even after drying. By strategically incorporating gaps between sections of ink on both facet, designers achieve exact management over the folding path of the sheet.

The self-folding course of is triggered by subjecting the flat sheet to warmth utilizing sizzling water. On account of this warmth publicity, the bottom sheet undergoes shrinkage. Throughout this course of, the ink, which displays resistance to shrinking, performs a pivotal position, main the fabric to spontaneously fold into a posh origami-like construction.

“My crew and I found learn how to use accessible instruments and supplies to create self-folding 4D objects,” added Narumi. “Primarily, we’re creating flat sheets with origami patterns on them, and these patterns might be complicated, taking even a talented origami artist hours to type. However because of our particular course of, you possibly can pour sizzling water over these flat sheets and watch as they spring into complicated 3D shapes in a matter of seconds.”

Researchers have expressed enthusiasm for the distinctive approach’s vital potential throughout numerous functions. Amongst these, the style trade stands to profit, because it usually grapples with materials wastage, notably within the context of bespoke designs. The capability of the expertise to move 4D printed gadgets whereas they continue to be flat affords an interesting decision to deal with logistical and storage obstacles, rendering it a practical choice for catastrophe restoration circumstances. Important gadgets like medical gear might be printed as flat shapes and remodeled into totally useful 3D objects on-site.

As acknowledged by the researchers, the 4D printing course of is at the moment present process steady exploration and growth, offering perception into a possible future the place fast and waste-free fabrication might grow to be a actuality. Researchers acknowledged they “eagerly anticipate” its sensible implementation and influence on various industries.

4D printing: The subsequent frontier in 3D manufacturing

Tianjin College researchers from China succeeded in 4D printing a self-propelling smooth robotic able to impartial motion. Constructed with a liquid crystal elastomer materials, the robotic featured a tube-like construction that underwent self-assembly upon publicity to warmth. By cleverly programmed fold patterns, the researchers induced pressure throughout the robotic’s physique, enabling it to roll in a fashion much like a log. Notably, this 4D printed smooth robotic showcased superior capabilities, together with traversing flat surfaces, ascending a 20° incline, and efficiently carrying a load as much as 40 occasions its personal mass.

Researchers from the College of Stuttgart and the College of Freiburg developed a novel technique of 4D printing wearable medical gadgets that might self-adjust to the affected person’s anatomy. Impressed by the propagation mechanism of the air potato plant (Dioscorea bulbifera), the printed methods have been pre-programmed to hold out complicated actions when uncovered to moisture. The crew efficiently leveraged the strategy to 4D print a self-tightening orthotic wrist splint that wrapped across the affected person’s arm by itself.

What does the way forward for 3D printing for the subsequent ten years maintain?

What engineering challenges will have to be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you searching for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a number of roles within the trade.

Featured picture reveals 2D layers for 4D designs. Though the printed origami sheets are basically flat, they mix many layers of various inks atop and beneath the central heat-shrink sheet materials. A primer helps inks keep on with the sheet, even when moist. The black ink is what resists the shrinking to permit folds to happen. A white layer supplies a clean canvas for a shade layer. And a ultimate clear layer protects all of these beneath. Picture through Koya Narumi.