The mixing of residence and office over the previous couple of years has turn out to be the norm. Kitchen tables have turn out to be desks, spare rooms now double up as places of work, and for an inventor, a storage generally is a toy workshop.

For Jack Peach, Key Lead Innovation Engineer at main world toy firm Mattel, the latter is the place the inklings of early product growth for brand new toys at Fisher-Value, designed to encourage, entertain, and develop youngsters via play, all occurs.

Assembly with TCT over Zoom, surrounded by store instruments and electronics, Peach’s workshop is full of, not simply the stuff of children’ goals, but in addition a number of toys that will be a dream for a lot of engineers.

And as Peach instructed TCT: “Fabricating prototype toys in a house workplace will be difficult with out the proper instruments.”

Two of these instruments, and a few of the newest additions to Peach’s assortment, are a MakerBot METHOD and METHOD X, each skilled desktop FDM printers, one designed for idea modelling and prototyping, the opposite for purposeful protoypes and instruments, from the newly unified UltiMaker. Amongst the hand instruments, grinder and soldering irons, it was the pandemic that led Peach, who has been working within the toy trade for over 15 years and, like many, discovered himself working from residence in early 2020, to lastly pull the set off on putting in a 3D printer.

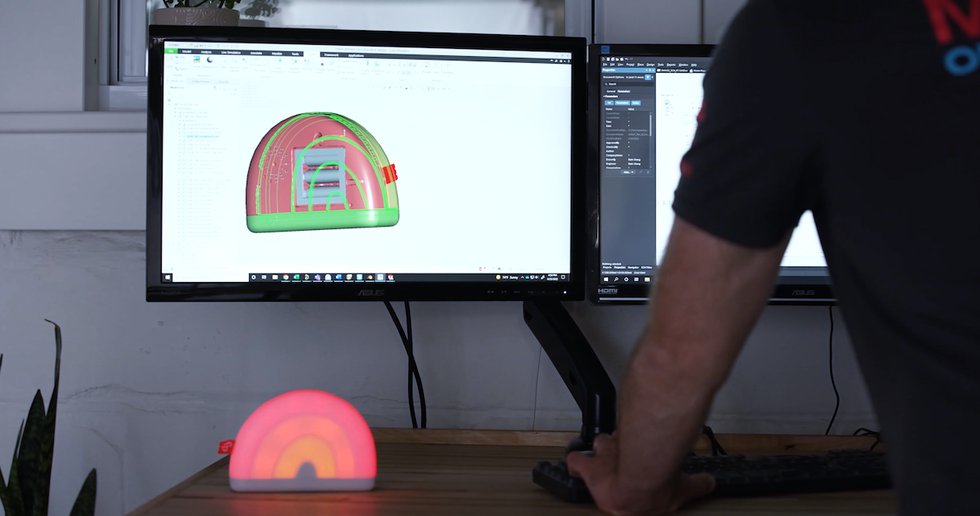

Previous to that, Peach and his crew had been already using a spread of digital design instruments to supply new toy ideas. That workflow usually concerned prototyping with a wide range of woodworking, metals and polymer store instruments earlier than sharing with Mattel’s innovative machine store to create purposeful components that may very well be demonstrated in a pitch assembly earlier than sharing with model companions and testers. Now, with 3D printing capabilities in-house, Peach is ready to rapidly mock up designs, check mechanical performance, show out electronics, and rapidly share and consider bodily working fashions.

“At residence, earlier than the printer, I may do actually crude prototypes,” Peach defined, demonstrating with an instance of a fancy plastic toy mannequin which might be extremely tough to prototype utilizing conventional strategies. “On this case, I’d attain out to our fabulous CNC store at Fisher-Value. They’ve industrial sized CNCs, SLA 3D printers – they undoubtedly have all of the instruments. I’d undergo that workflow and put in my job and request it to be manufactured.”

Usually that workflow meant a number of days earlier than a component was prepared, and even longer if design adjustments wanted to be made and prototyped once more. Given the hit or miss ratio within the toy enterprise – Peach suggests if only one out of 100 concepts makes it to the cabinets of a toy retailer, that’s fairly good going – these time financial savings are invaluable.

“3D printing permits us to make use of our time extra effectively and successfully,” Peach stated. “We actually don’t wish to print each single idea that we brainstorm however when the thought is true, 3D printing is unquestionably a time saver, and permits us to give attention to different features of the idea. As an alternative of manually fabricating it or figuring out toolpaths for the CNC, you’ll be able to spend that point creating your idea pitch, or possibly engaged on the electronics, {hardware}, electronics software program, or possibly the audio that’s going to enter that mannequin. So you possibly can be multitasking after which all of your components come off, you’ll be able to put it collectively and also you’re able to go to point out it to the model crew.”

The pliability and freedom that comes with having such capabilities in your desk makes it potential to print one iteration whereas already engaged on the following. Peach recollects an instance from a current Saturday morning whereas on the brink of take his youngsters to soccer apply, when he had a sudden spark of inspiration.

“We had this one off-the-shelf product and I’m pondering, if we add some lights and sounds and add a special mechanism to it, possibly this may very well be a enjoyable sport?” Peach recollected. “My youngsters and I had been speaking about it after which proper earlier than we left, I drew it up actual fast and despatched over to the printer. Then we left for the sport. Hours later, we got here again, and it was able to go. We pulled out the construct plate, cleaned it up after which began taking part in with it.”

Peach says, whereas 3D printing permits him to check out concepts extra quickly, the expertise has additionally impressed his family, whether or not it’s constructing a photo voltaic system for homework or serving to to create elements for pressured rockets on the native Boy Scouts den. “It’s a tremendous software,” Peach provides, and with three youngsters at residence, what higher consultants may you hope for to get some certified suggestions?

Peach described a current instance of an early-stage toy he had been engaged on some electronics and motor controls for: “My youngest son simply grabbed it, introduced it upstairs, and was taking part in with it. I ended up taking a fast little video to point out the designers he was having time and he had a smile on his face. It’s nonetheless a tough type however you’ll be able to see that there’s one thing there.”

Since its founding in 1945, Mattel has been famend for creating merchandise throughout iconic manufacturers together with Barbie, Scorching Wheels, Fisher-Value, American Lady, Thomas & Buddies, UNO, Masters of the Universe, Monster Excessive and MEGA. The corporate even launched its personal sub-300 USD 3D printer in 2016, a contemporary spin on its Sixties ThingMaker, which allowed youngsters to suppose up and print their very own creations. Whereas it might have supplied its younger prospects the instruments to print their very own toys from residence, Mattel isn’t presently deploying 3D printing for mass manufacturing purposes, although Peach does have some attention-grabbing ideas on how that would look.

“I believe possibly far into the long run,” Peach says, emphasising the ‘far’, “maybe we’ll have a virtuous cycle the place toys will be printed at residence after which performed with after which the fabric may very well be recycled or a part of it may very well be recycled and possibly you possibly can reprint that into a brand new toy.”

Whereas injection moulding should still be the best way to go given Mattel’s big manufacturing volumes – its merchandise can be found in 150 international locations – Peach emphasises that for brand new toy growth, which generally takes round 18 months relying on rising developments and complexity, “3D printing has been a sport changer.”

“3D printing permits you to create a number of components and assemblies that had been very difficult to make in any other case,” Peach concluded. “We’re engaged on the very entrance finish, the early prototypes, after which it will get despatched on to different groups to actually develop and make it designed for manufacturing. In my case, you’ll be able to print these very advanced assemblies in a short time and actually simply attempt to get to that magic spot. I believe that while you’re pondering of a toy which may have some type of characteristic otherwise you flip this knob and the transformation, it’s good to see that just about or drawn out however till you get your palms on it and also you perceive the way it’s going to work, even when it’ll work, then the magic shouldn’t be there. When you get it collectively, then you’ll be able to actually see that, ‘wow, this can be a actually cool toy,’ and the youngsters are going to have time with it.”