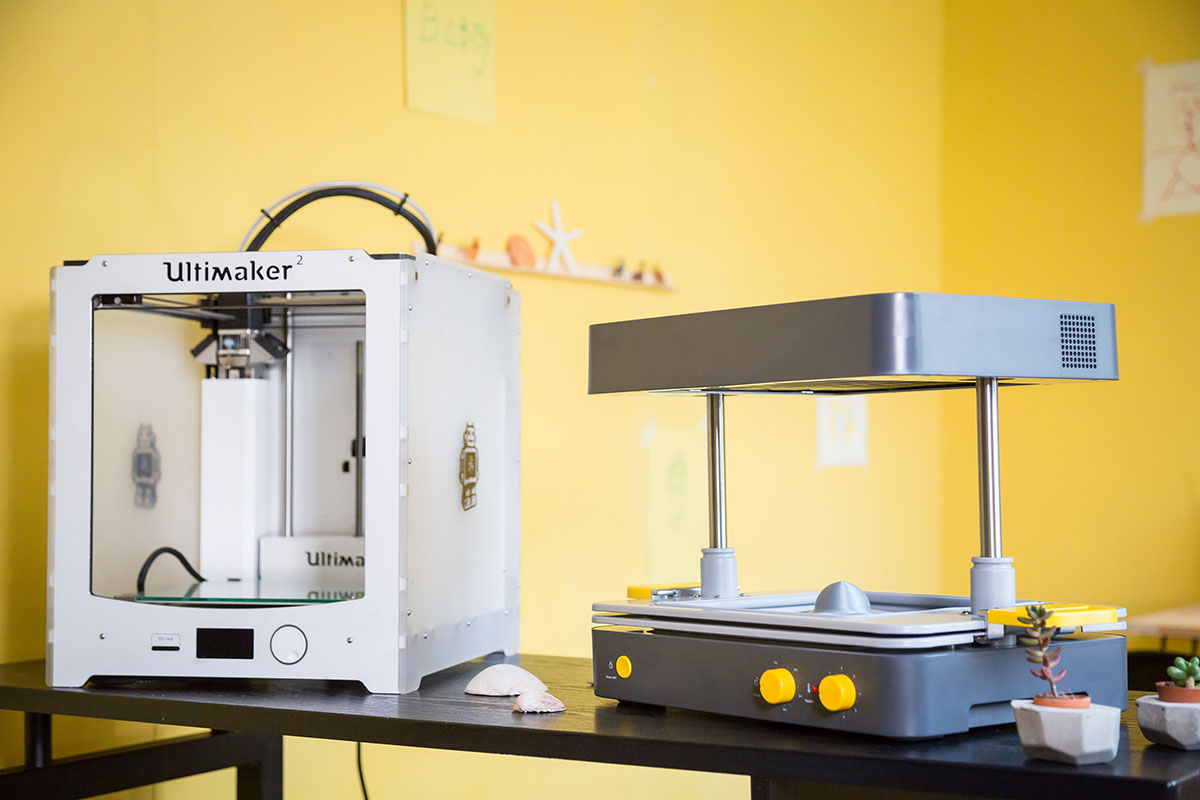

A 3D printer paired with a vacuum former can create objects with intricate shapes and particulars that will be in any other case tough or unattainable to create with both expertise alone. The vacuum former can create detrimental molds of 3D-printed objects, which may then be used to create constructive copies out of quite a lot of supplies. This pairing of applied sciences opens up a world of potentialities for creating personalized, one-of-a-kind objects.

Whether or not you’re a chocolatier or chef seeking to make distinctive designs to your tasty treats, an artist designing customized soaps, candles, and ceramics or you’re needing light-weight casings for electronics, auto or aerospace corporations, and extra, utilizing a 3D printer mixed with a vacuum former provides you a complete new option to replicate your designs for a low value.

What’s Vacuum Forming?

A vacuum former is a kind of plastic-forming machine that makes use of a vacuum to suck heated plastic sheets round a kind to create a mildew. The shape used to create the mildew could be 3D printed, hardened clay, glass, cardboard, sturdy meals objects, discovered objects from nature (shells and so forth) or reused objects and rather more so long as they don’t have an overhang.

After you have positioned your kind onto the mattress of the vacuum former, it then heats the plastic sheet till it’s delicate and pliable. As soon as able to kind, the sheet is lowered and draped throughout the shape and a vacuum sucks the heated plastic into a good seal across the kind to create a mildew of the unique object.

The plastic cools and hardens into the form of the unique kind and creates a mildew that may then be used to fill with chocolate, clay, resin, plaster, jesmonite, concrete, gelatin, cleaning soap, candle wax and rather more to duplicate the form.

The vacuum former can be utilized to create advanced shapes that will be tough or unattainable to create with different strategies. It is usually comparatively quick, low value, and easy for adults in addition to youthful kids and college students.

Total, vacuum forming is a flexible and easy-to-use technique for shortly replicating and creating advanced shapes out of plastic.

How a Vacuum Former Can Enhance Manufacturing Throughput

3D printers have grow to be indispensable instruments throughout a large number of industries. They’re offering robust aggressive benefits by permitting organizations to iterate new designs rather more quickly and cost-effectively than ever earlier than.

When printing a single half or prototype, a 3D printer is an ideal answer, permitting organizations to keep away from pricey and time-consuming outsourcing for components manufacturing. However when dozens of copies are wanted, the pace of a 3D printer can grow to be a problem. That is very true in instructional environments the place lecturers wrestle to make sure all college students have ample entry to the out there 3D printers.

By including a desktop vacuum former into the combo, you may vastly enhance the throughput for producing a number of copies of 3D-printed components. After 3D printing a single copy of a component, it may be duplicated in a matter of seconds utilizing vacuum-forming expertise. On this manner, a vacuum former can considerably enhance the utility of a small variety of 3D printers, permitting components to be produced rather more quickly than with 3D printing alone.

Why are 3D Printed Fashions Most popular for Use with a Vacuum Former?

3D printed kinds are sometimes most popular over different supplies relating to vacuum forming as a result of they’re extra correct, sturdy, stable, and versatile. With 3D printed kinds, you may create vacuum-formed components with higher dimensional accuracy and repeatability, particularly while you make your authentic design from heat-resistant supplies so they don’t warp or grow to be brittle with a number of makes use of.

If a 3D printed mannequin is created with FDM (Fused Deposition Modeling) 3D printers, they might have to be sanded or handled in an acetone tub to easy them and take away strains from layers that will present up within the vacuum-formed mildew.

Through the design course of, it’s straightforward to create a kind with a draft angle so the shape could be simply faraway from the mildew, spherical corners to cut back the possibility of webbing, and permit for together with vent holes to make sure that the main points of the design have ample suction from the vacuum under to tug the heated plastic into these areas.

After you have designed your first kind and examined your first vacuum-formed mildew, it’s straightforward to extend or lower the dimensions of the unique, and make modifications to the draft angles, corners, and vent holes in a matter of minutes. If that you must make an adjustment or just need to provide quite a lot of completely different sizes of your completed product you merely resend your design to the 3D printer and make one other kind.

A Extensive Number of Purposes for Vacuum Forming with 3D Printed Types

Vacuum forming could be very well-known for its use as packaging for merchandise, however there are dozens of different methods by which vacuum forming is getting used. Under are a couple of examples of how vacuum forming is offering lower-cost choices and simpler options for varied industries and academic establishments.

• Protecting circumstances

• Inside panels and trims for aerospace and automotive functions

• Meals, sweet, and chocolate molds

• Seed trays and flower tubs within the agricultural business

• Signage

• Lighting covers, panels, and diffusers

• Client digital enclosures

• Film, tv, and cosplay props

• Medical gear and enclosures

• Architectural fashions

• Mannequin making for automobiles, boats, plane miniatures

• Cleaning soap and candle molds

• Artwork initiatives

• Ceramic and plaster molds

• Molds for pet treats and chicken feeders

• Silicone mildew making

• Costume design

• Academic initiatives for the classroom

• A lot, rather more!

Be taught Extra about 3D Printers and Vacuum Formers

For extra details about desktop 3D printers and vacuum formers, please go to our web site.

We’ve got quite a lot of 3D printers to select from and can assist you to determine the best choice to your dwelling, enterprise or classroom wants in addition to info on which kinds of vacuum forming sheets you will have to your private or enterprise initiatives.

We additionally provide instructional reductions on quite a lot of our 3D printers and the Mayku FormBox Vacuum former so please make certain to say that you’re an educator in case you are trying to find digital fabrication and vacuum forming tech to your college and classroom!