Spanish 3D printer producer BCN3D have launched their new BCN3D Omega I60 industrial FFF 3D printer.

The Omega I60 is designed as an all-in-one industrial 3D printer for the manufacturing of huge and robust prototypes and end-use components, significantly tooling, jigs, and fixtures. That includes an upgraded model of BCN3D’s signature Unbiased Twin Extrusion (IDEX) know-how, this new 3D printer affords a big 3D print quantity, a high-temperature warmth chamber, and a direct-drive high-speed extruder for quick 3D print speeds.

BCN3D has additionally unveiled their materials portfolio for the Omega I60, which incorporates customized formulations specifically chosen to cater to particular verticals.

Introduced on June 14th throughout a particular reside stream occasion held at their Barcelona headquarters, the launch of the Omega I60 coincides with the BCN3D’s eleventh anniversary. Since releasing their first 3D printer in 2015, the BCN3D Sigma, the corporate has distributed over 10,000 items worldwide throughout greater than 100 factors of sale.

Key BCN3D prospects embrace the likes of worldwide automotive producer Nissan, French multinational Saint Gobain, and additive producer of end-use components for cross-country vehicles, Prodrive.

Key options of the BCN3D Omega I60

The Omega I60 incorporates an upgraded model of BCN3D’s IDEX know-how. Based on the corporate, IDEX is the one extrusion system able to 3D printing with two unbiased toolheads concurrently.

As such, the IDEX system is marketed as doubling productiveness, and enabling the manufacturing of components with help with out cross-contamination. The Omega I60’s up to date IDEX system ensures that the X motors stay stationary throughout the 3D printing course of, minimizing inertia and accelerating 3D print speeds.

BCN3D’s HAQ-XY Kinematics movement structure has additionally acquired an improve for the Omega I60. This improved kinematic system consists of an optimized pulley system, which is alleged to considerably cut back torsional moments alongside the X-axis throughout the 3D printing course of. This removes the potential for deformations to kind within the X-axis, finally enhancing the standard of the 3D printed components.

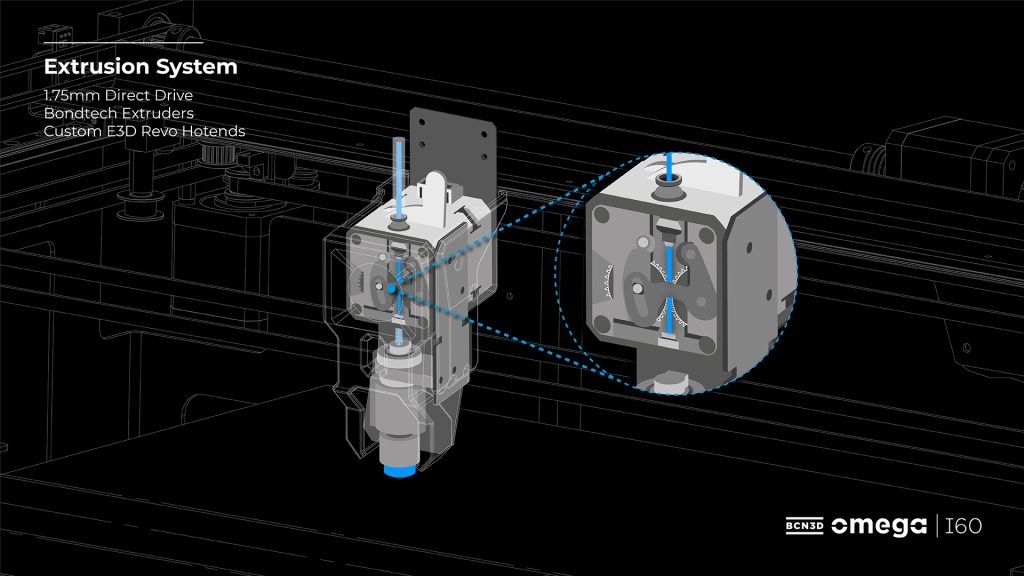

The extrusion system itself is alleged to be “industry-leading,” with the Omega I60 geared up with 1.75mm direct drive Bondtech LGX Professional extruders. Based on BCN3D, this technique supplies optimized management and precision. Customized E3D Revo hotends are additionally included, stated to be extremely dependable and supply easy-swap nozzle change capabilities.

Quick 3D print pace can also be key to the Omega I60, with the 3D printer able to producing components at 300 mm/s, and speed up at speeds of as much as 10 m/s2. To realize these high-speeds, the Omega I60 incorporates built-in accelerometers, 32 bit electronics, and a customized model of Marlin 2.1 firmware. BCN3D claims that their new providing is at present the one high-speed 3D printer available on the market to incorporate IDEX know-how.

An industrial scale 3D printer optimized for the manufacturing of large-scale end-use and prototype components, the Omega I60 additionally affords a considerable construct quantity of 450 x 300 x 450mm (60 liters).

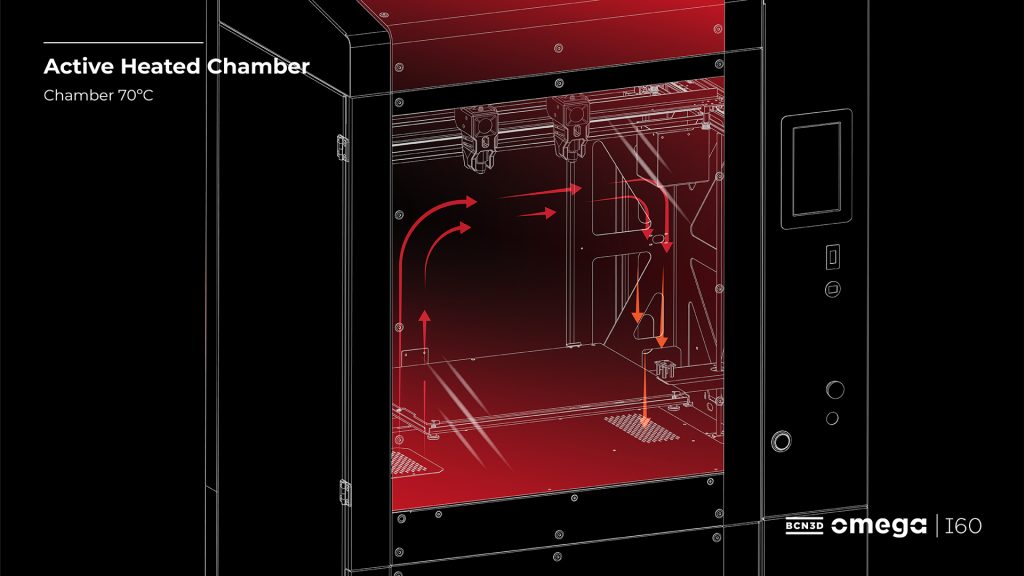

The Omega I60’s energetic heated construct chamber can also be notable. This chamber can warmth as much as 70℃, making it preferrred for 3D printing with engineering grade polymers comparable to ASA, PA, ABS, and bolstered PA.

With optimized temperature management, the chamber is alleged to reduce the formation of inner stresses by guaranteeing the uniform building of 3D printed components. By heating the chamber near the glass transition temperature of the supplies, the construct chamber can successfully stop points comparable to cracking and warping.

The Omega I60 additionally consists of BCN3D’s Materials Operations System (MOS), an built-in module which permits customers to manage the humidity and temperature of the fabric for a 3D print. The MOS can attain temperatures of as much as 75℃, and supplies an RH under 10%.

By means of the MOS, compromised materials will be simply recovered. Moreover, filaments will be preheated earlier than a 3D print begins, important when utilizing engineering filaments with excessive warmth deflection temperatures. Omega I60 MOS additionally affords automated filament loading and unloading, additional streamlining the economic 3D printing course of.

The Omega I60 additionally incorporates XYZ autocalibration. Utilizing piezoelectric sensors, this characteristic removes the potential for human error, and is alleged to ensure first layer adhesion.

Further options provided with the brand new Omega I60 embrace a built-in digital camera, a versatile construct plate, an uninterruptible energy provide for safe 3D printing, a barcode sensor for spool and parts recognition, a 7” capacitive contact display screen, and a andon gentle.

A HEPA and Carbon filter, Filament Runout Sensor (FRS), Security Pause operate, and an emergency cease button have additionally been added for optimum 3D print security. The Omega I60 additionally consists of WiFi and Ethernet connectivity.

BCN3D additionally affords a cloth portfolio for the Omega I60, chosen to cater to verticals comparable to tooling, jigs and fixtures, short-run manufacturing, masking, massive prototyping, manufacturing line replacements, and end-use components. These supplies embrace Omega Impression ASA, Omega Resistant Nylon, Omega Tooling CF, and Omega Help.

The Omega I60 possesses open materials compatibility, permitting customers to make use of filaments not offered by BCN3D.

Technical specs desk and pricing

Pricing for the BCN3D Omega I60 begins at €19,995 ($21,995 USD), with the primary items set to be shipped on September fifteenth 2023.

Potential prospects can safe their Omega I60 right this moment by contacting BCN3D at [email protected], or by any of BCN3D’s official distribution companions.

| 3D printing know-how | Fused Filament Fabrication (FFF) |

| Structure | IDEX (Unbiased Twin Extruder System) |

| Print quantity | 450 x 300 x 450mm / 60L |

| Heated chamber temperature | 70℃ |

| Print pace | 300 mm/s |

| Print acceleration | 10 m/s2 |

| Extrusion system | 1.75mm Direct drive Bondtech LGX Professional extruders |

| WiFi / Ethernet connectivity? | Sure |

| Supplies | Open filament system |

Subscribe to the 3D Printing Business e-newsletter to make sure you sustain with the newest 3D printing information. You can even comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing {industry}? Go to 3D Printing Jobs to view a number of accessible roles and kickstart your profession.

Featured picture exhibits the brand new BCN3D Omega I60 industria 3D printer. Picture by way of BCN3D.