Perhaps you may’t inform a e-book from its cowl, however in accordance with researchers at MIT you could now be capable of do the equal for supplies of all kinds, from an airplane half to a medical implant. Their new strategy permits engineers to determine what’s occurring inside just by observing properties of the fabric’s floor.

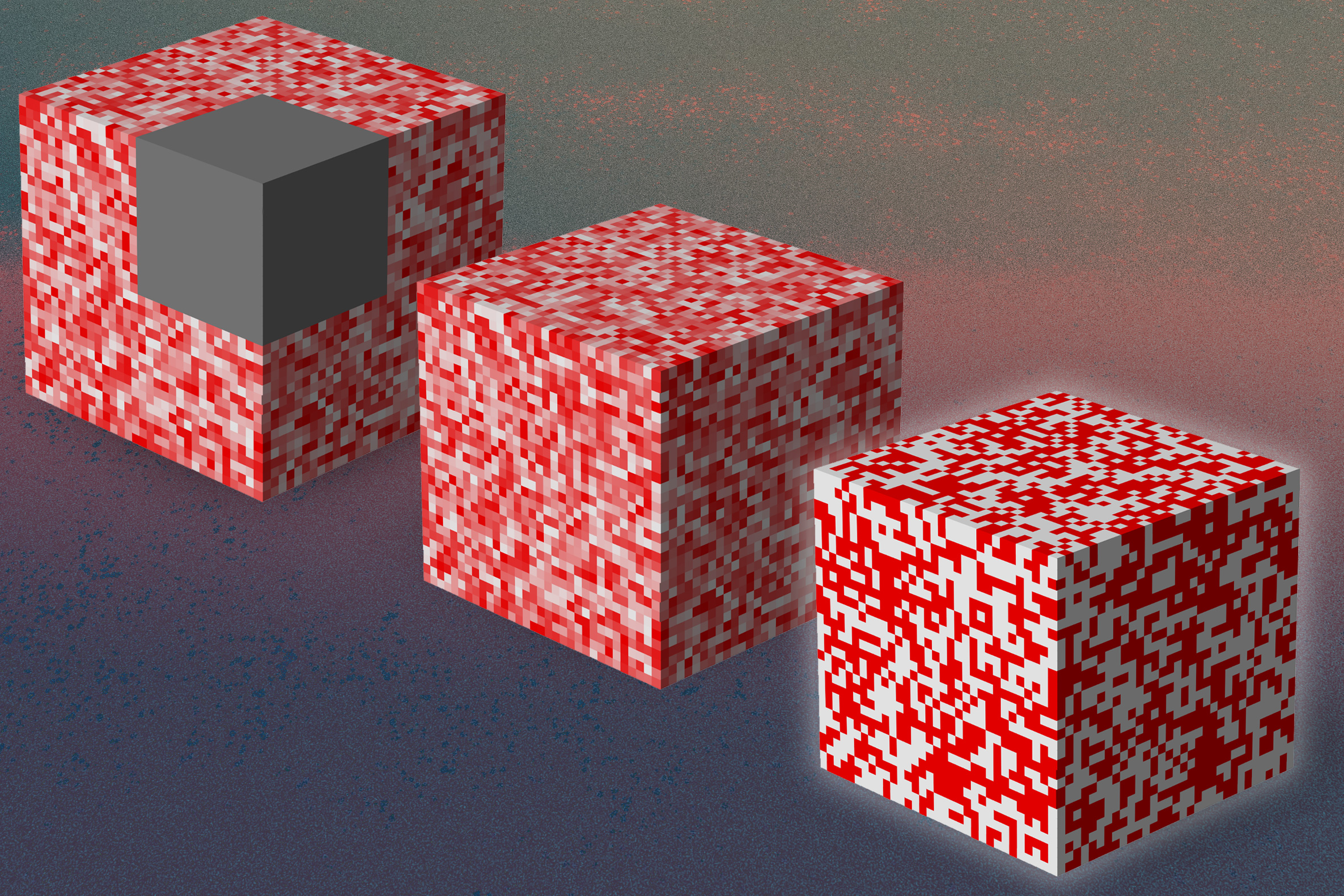

The staff used a kind of machine studying often called deep studying to check a big set of simulated knowledge about supplies’ exterior drive fields and the corresponding inside construction, and used that to generate a system that might make dependable predictions of the inside from the floor knowledge.

The outcomes are being printed within the journal Superior Supplies, in a paper by doctoral scholar Zhenze Yang and professor of civil and environmental engineering Markus Buehler.

“It’s a quite common downside in engineering,” Buehler explains. “When you’ve got a chunk of fabric — possibly it’s a door on a automotive or a chunk of an airplane — and also you wish to know what’s inside that materials, you may measure the strains on the floor by taking photographs and computing how a lot deformation you might have. However you may’t actually look inside the fabric. The one approach you are able to do that’s by chopping it after which trying inside and seeing if there’s any form of injury in there.”

It is also attainable to make use of X-rays and different methods, however these are typically costly and require cumbersome gear, he says. “So, what we’ve got carried out is principally ask the query: Can we develop an AI algorithm that might have a look at what’s occurring on the floor, which we will simply see both utilizing a microscope or taking a photograph, or possibly simply measuring issues on the floor of the fabric, after which making an attempt to determine what’s truly occurring inside?” That inside data may embrace any damages, cracks, or stresses within the materials, or particulars of its inside microstructure.

The identical form of questions can apply to organic tissues as properly, he provides. “Is there illness in there, or some form of progress or adjustments within the tissue?” The purpose was to develop a system that might reply these sorts of questions in a totally noninvasive approach.

Reaching that objective concerned addressing complexities together with the truth that “many such issues have a number of options,” Buehler says. For instance, many various inside configurations may exhibit the identical floor properties. To take care of that ambiguity, “we’ve got created strategies that may give us all the chances, all of the choices, principally, that may consequence on this explicit [surface] state of affairs.”

The approach they developed concerned coaching an AI mannequin utilizing huge quantities of information about floor measurements and the inside properties related to them. This included not solely uniform supplies but additionally ones with completely different supplies together. “Some new airplanes are made out of composites, so that they have deliberate designs of getting completely different phases,” Buehler says. “And naturally, in biology as properly, any form of organic materials will probably be made out of a number of elements and so they have very completely different properties, like in bone, the place you might have very mushy protein, after which you might have very inflexible mineral substances.”

The approach works even for supplies whose complexity just isn’t totally understood, he says. “With complicated organic tissue, we don’t perceive precisely the way it behaves, however we will measure the habits. We don’t have a idea for it, but when we’ve got sufficient knowledge collected, we will practice the mannequin.”

Yang says that the tactic they developed is broadly relevant. “It’s not simply restricted to strong mechanics issues, nevertheless it may also be utilized to completely different engineering disciplines, like fluid dynamics and different sorts.” Buehler provides that it may be utilized to figuring out quite a lot of properties, not simply stress and pressure, however fluid fields or magnetic fields, for instance the magnetic fields inside a fusion reactor. It’s “very common, not only for completely different supplies, but additionally for various disciplines.”

Yang says that he initially began enthusiastic about this strategy when he was finding out knowledge on a cloth the place a part of the imagery he was utilizing was blurred, and he puzzled the way it could be attainable to “fill within the clean” of the lacking knowledge within the blurred space. “How can we get well this lacking data?” he puzzled. Studying additional, he discovered that this was an instance of a widespread challenge, often called the inverse downside, of making an attempt to get well lacking data.

Growing the tactic concerned an iterative course of, having the mannequin make preliminary predictions, evaluating that with precise knowledge on the fabric in query, then fine-tuning the mannequin additional to match that data. The ensuing mannequin was examined towards circumstances the place supplies are properly sufficient understood to have the ability to calculate the true inside properties, and the brand new technique’s predictions matched up properly towards these calculated properties.

The coaching knowledge included imagery of the surfaces, but additionally numerous other forms of measurements of floor properties, together with stresses, and electrical and magnetic fields. In lots of circumstances the researchers used simulated knowledge primarily based on an understanding of the underlying construction of a given materials. And even when a brand new materials has many unknown traits, the tactic can nonetheless generate an approximation that’s ok to supply steerage to engineers with a basic route as to the best way to pursue additional measurements.

For instance of how this technique could possibly be utilized, Buehler factors out that at present, airplanes are sometimes inspected by testing a number of consultant areas with costly strategies corresponding to X-rays as a result of it might be impractical to check the complete airplane. “It is a completely different strategy, the place you might have a a lot inexpensive approach of gathering knowledge and making predictions,” Buehler says. “From which you can then make selections about the place do you wish to look, and possibly use dearer gear to check it.”

To start with, he expects this technique, which is being made freely obtainable for anybody to make use of by the web site GitHub, to be largely utilized in laboratory settings, for instance in testing supplies used for mushy robotics purposes.

For such supplies, he says, “We are able to measure issues on the floor, however we don’t know what’s occurring a variety of instances inside the fabric, as a result of it’s made out of a hydrogel or proteins or biomaterials for actuators, and there’s no idea for that. So, that’s an space the place researchers may use our approach to make predictions about what’s occurring inside, and maybe design higher grippers or higher composites,” he provides.

The analysis was supported by the U.S. Military Analysis Workplace, the Air Pressure Workplace of Scientific Analysis, the GoogleCloud platform, and the MIT Quest for Intelligence.