| Jun 20, 2023 |

|

|

|

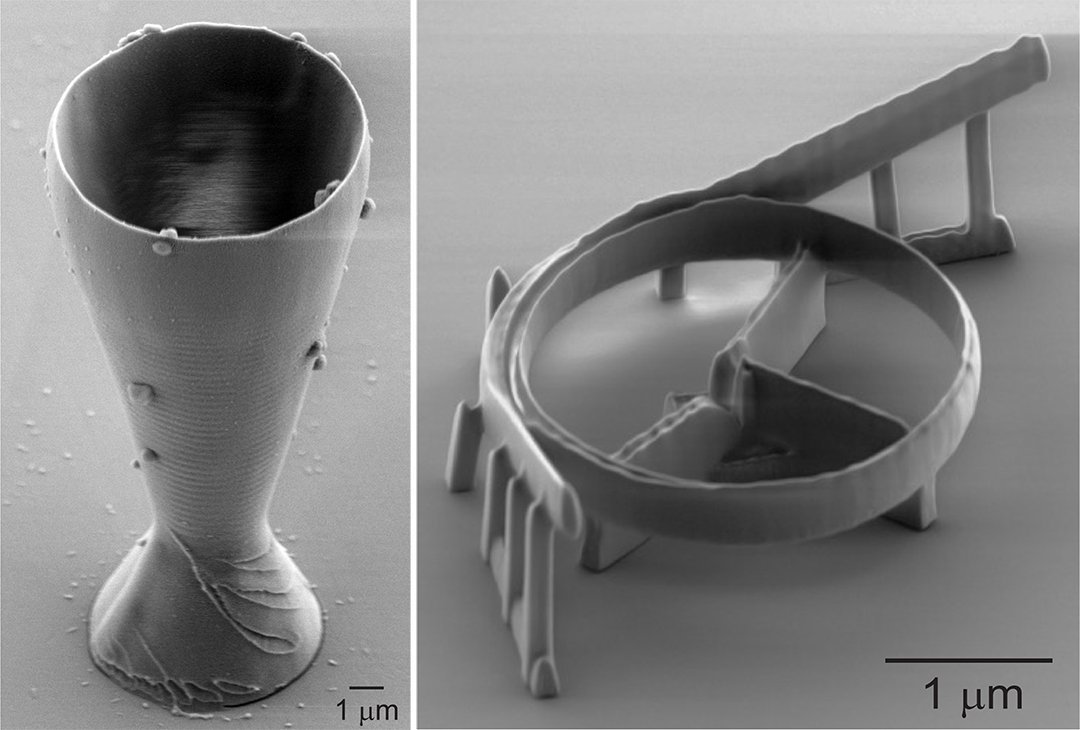

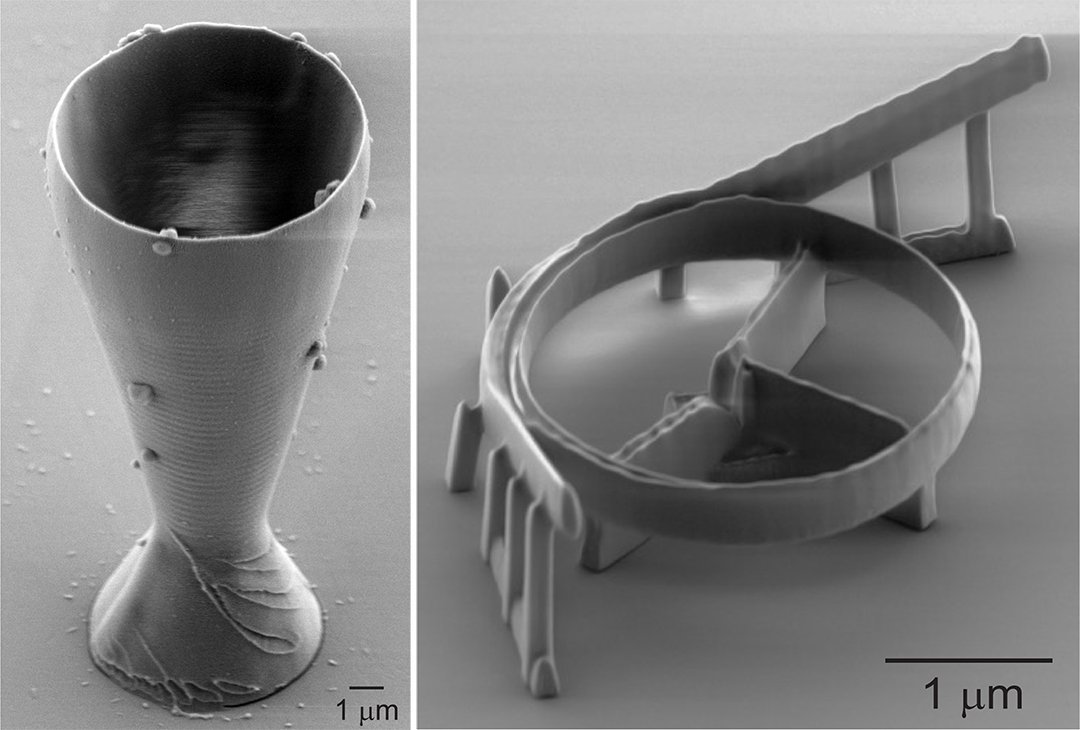

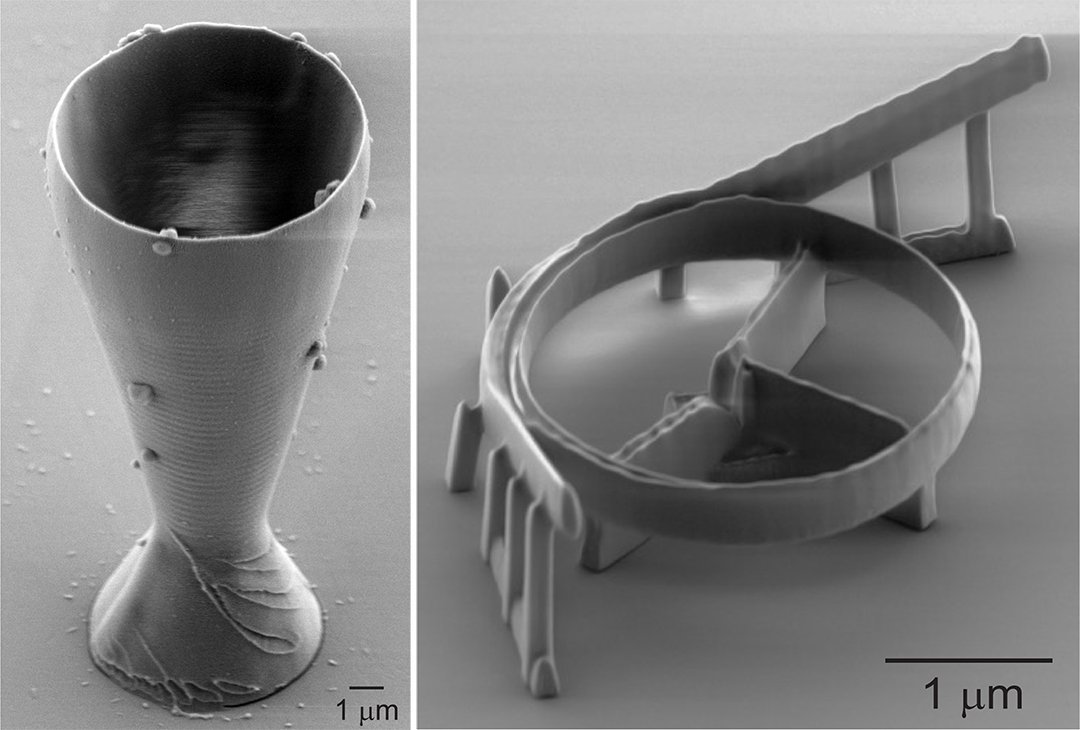

(Nanowerk Information) Researchers have 3D-printed the world’s smallest wine glass—almost indistinguishable with the bare eye—with a rim smaller than the width of a human hair. However the concept wasn’t to cater to extraordinarily mild drinkers. Relatively, the glass was printed to show a brand new simplified method for creating silica glass constructions for a variety of functions from telecommunications to robotics.

|

|

Developed at KTH Royal Institute of Expertise in Stockholm, the brand new method surmounts issues—comparable to the necessity for thermal therapy—when 3D-printing important silica glass parts, says KTH Professor Frank Niklaus.

|

|

The analysis is revealed in Nature Communications (“Three-dimensional printing of silica glass with sub-micrometer decision”).

|

|

| The world’s smallest 3D-printed wineglass (left) and an optical resonator for fiber optic telecommunications, photographed with scanning electron microscopy at KTH Royal Institute of Expertise. The rim of the glass is smaller than the width of a human hair. (Picture: KTH)

|

|

Niklaus says it may be used for personalized lenses for medical equipment that carry out minimally invasive surgical procedure, micro-robots that navigate excessive environments, or filters and couplers for fiber optic networks, to call a couple of functions.

|

|

One such fiber optic filter was produced within the examine. The researchers present that the method can print units straight on the tip of an optical fiber as skinny as a strand of a human hair.

|

|

“The spine of the web relies on optical fibers fabricated from glass. In these techniques, every kind of filters and couplers are wanted that may now be 3D printed by our method,” says co-author Kristinn Gylfason, an affiliate professor of Micro- and Nanosystems at KTH. “This opens many new potentialities.”

|

|

The strategy drastically reduces the vitality wanted to 3D print silica glass, which usually requires heating supplies as much as a number of hundred levels for hours, says the examine’s lead creator, Po-Han Huang, a doctoral scholar at KTH. “The benefit of our methodology is there’s no want for thermal therapy and the glass can face up to excessive warmth in functions.”

|

|

One other profit, he says, is that the tactic can produce silica glass utilizing available, industrial supplies.

|

|

Eliminating the necessity for thermal therapy will increase the likelihood for the method for use broadly in numerous software eventualities, he says. “The issues when integrating 3D printing strategies are often totally different for various functions. Though optimization of our methodology remains to be required for various functions, we imagine our methodology presents an vital and obligatory breakthrough for 3D glass printing for use in sensible eventualities.”

|

|

So what about that wineglass? Is it actually the world’s smallest? In spite of everything, individuals have already 3D printed a variety of demonstration objects, like statues and mannequin automobiles. Niklaus says the distinction is that this demo is in glass. “Undoubtedly no person has 3D printed a wineglass that consists of glass as-printed,” he says.

|