Resin printing differs from FDM 3D printing, and a few guidelines that apply to utilizing 3D printing helps are additionally completely different. Gambody needs to debate the important practices of orienting mannequin elements in your SLA/DLP/LCD 3D printer to realize the very best outcomes.

Remembering a number of guidelines for profitable resin printing of any mannequin is a should. And they’re all on the way you place the elements on the 3D printer mattress. Appropriate positioning eliminates many points and results in incredible tasks.

Learn additionally: Over 100 Enjoyable 3D Printer Initiatives

Resin Printing & SLA Help

You need to grasp when to make use of helps in 3D printing and study to orient the fashions appropriately on the printer mattress. There are some guidelines Gambody needs to share with you based mostly on a few of the incredible 3D printing tasks you will discover on gambody.com market.

Generally including resin print helps and choosing the density is just not sufficient. If you wish to efficiently use SLA help and create stunning and easy objects not ruined by post-processing work, look intently on the resin printing guidelines under.

Rule 1: Holding a Uniform Cross-Sectional Space

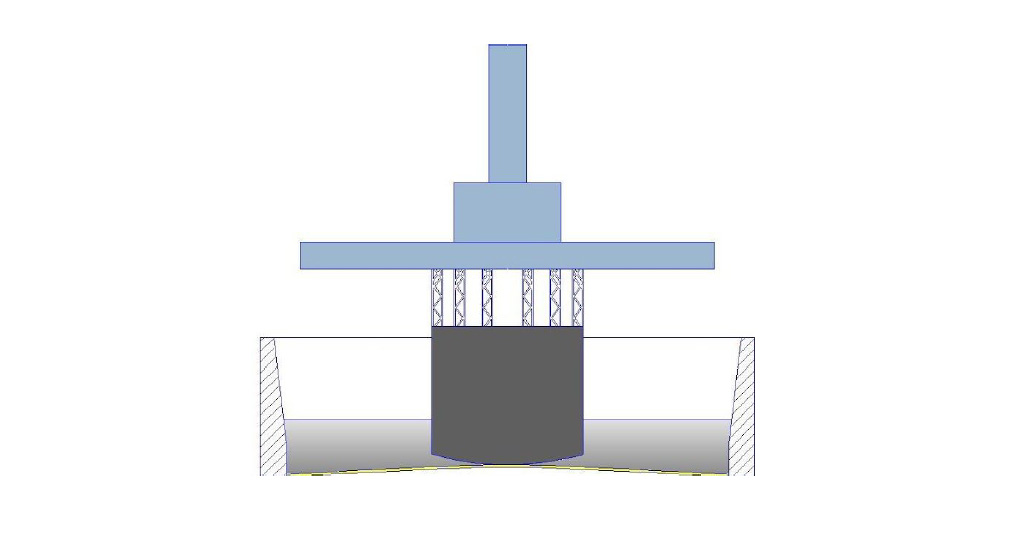

It’s a widespread rule to place 3D printing elements on the mattress completely at a 30% to 45% angle and use SLA help buildings. If you tilt the mannequin at these angles and use sufficient resin printing helps, you’ll be able to print practically each venture and make it look incredible.

It’s mandatory to keep up the uniform cross-sectional space of 3D printing layers. This manner, you’ll be able to keep away from getting seen layer traces.

Apart from, avoiding vital variations within the object areas can be finest. If such issues exist within the mannequin, attempt to orient them at an angle. The number of orientations can clear up many points and allow you to to take full benefit of 3D print helps.

Learn additionally: Greatest Tips about Easy methods to 3D Print With out Helps

Ignoring the thing positioning guidelines, you may expertise the next scenario. As you 3D print, the sudden look of a big cross-sectional space could cause a excessive suction drive on the resin movie. In consequence, your mannequin can simply tear off its SLA help.

Normally, hobbyists use extra inflexible helps to carry the 3D printing object in place. And when creating an enormous mannequin, it ought to be hole inside. Thus, a big cross-sectional quantity doesn’t essentially equal an enormous space.

And when you’re unsure, it’s best to keep away from abrupt transitions for higher resin printing outcomes. Listed below are a couple of examples.

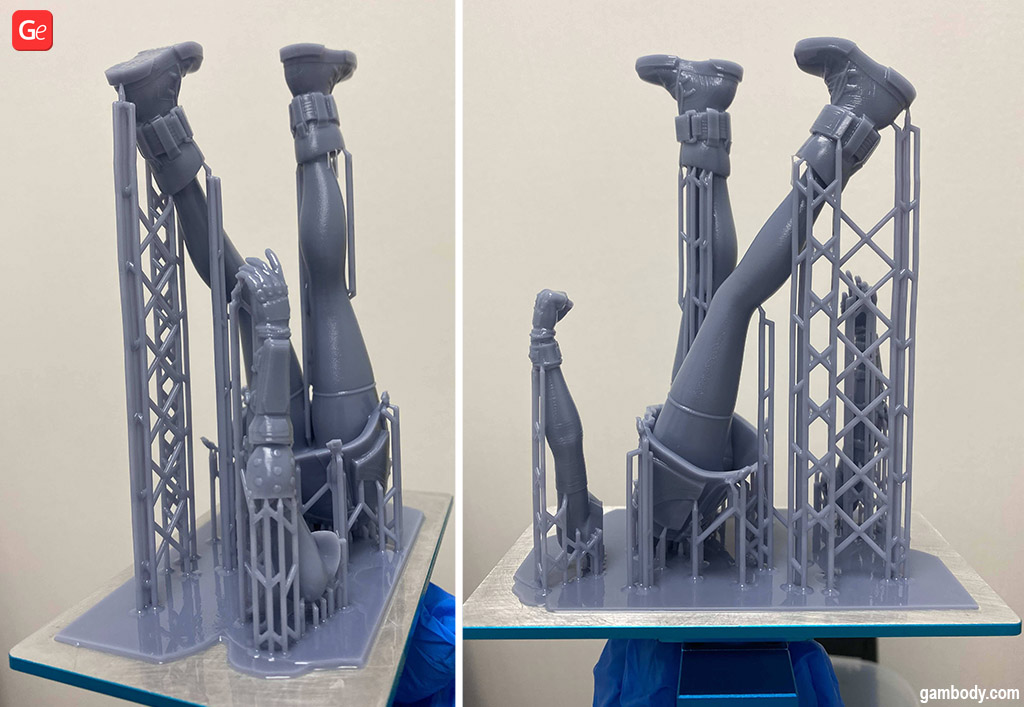

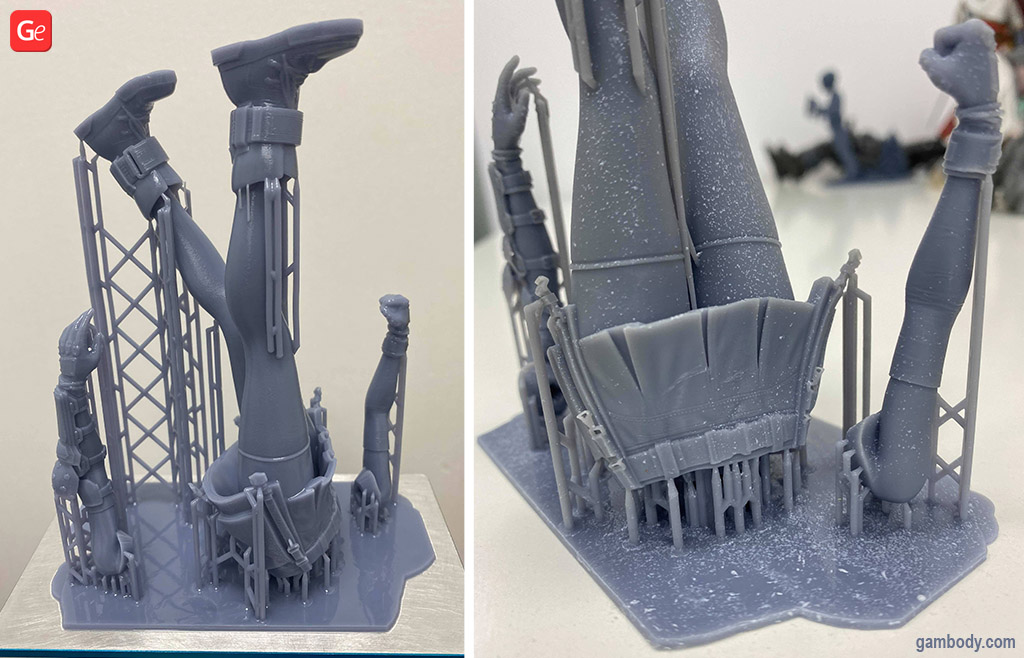

Instance 1: Tifa Lockhart

When resin printing Tifa Lockhart‘s legs, there was an issue with their complete quantity. Due to their giant space, it was essential to create an enormous adhesion space on the mattress. The mannequin didn’t rip off its help as a result of it was positioned appropriately for 3D printing.

Take note of how Tifa’s mannequin is positioned relative to the mattress. You’ll discover that its decrease portion is of extra appreciable quantity in comparison with the highest elements. Additionally, this object has no sharp modifications within the cross-sectional space. The skirt could cause the one doable drawback as a result of it has numerous quantity. However the skirt is hole and makes use of many SLA help buildings, which helps it keep adhesive to the constructing platform.

Tifa’s arms are manner simpler to make good. They’ve nearly the identical cross-section over your entire peak. On the similar time, they’re positioned at a slight angle to scale back the pull-off load and have an excellent distribution of it over the mattress space.

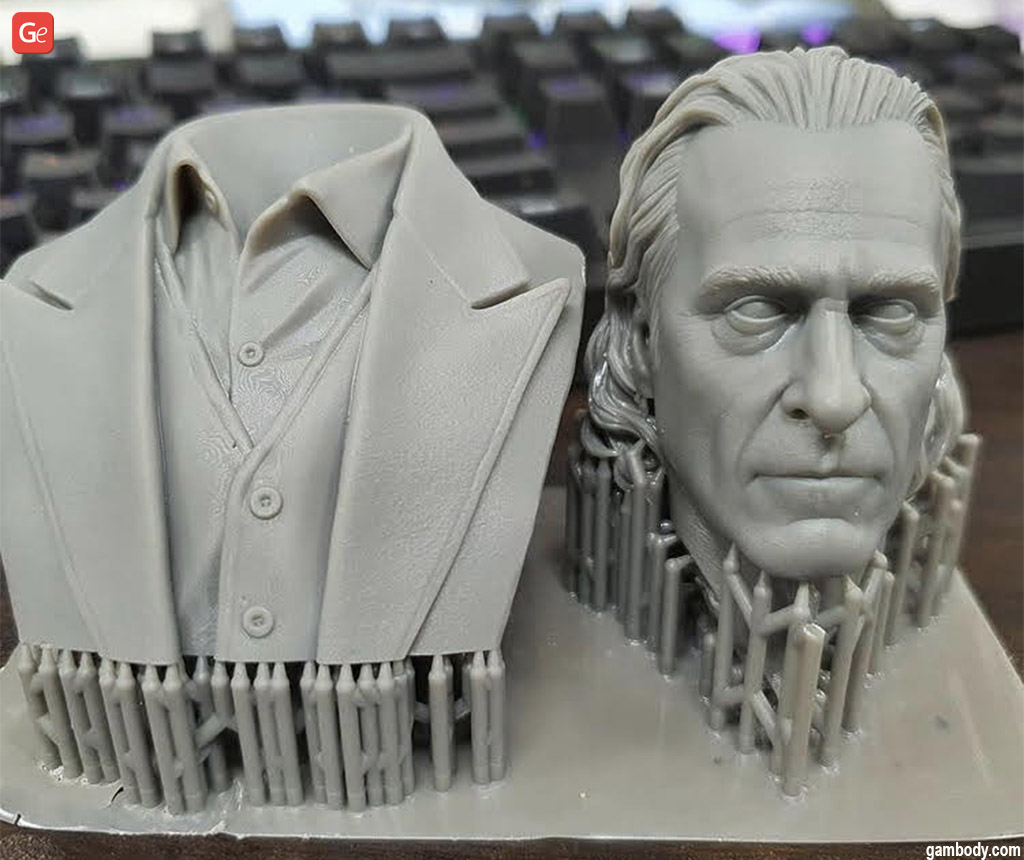

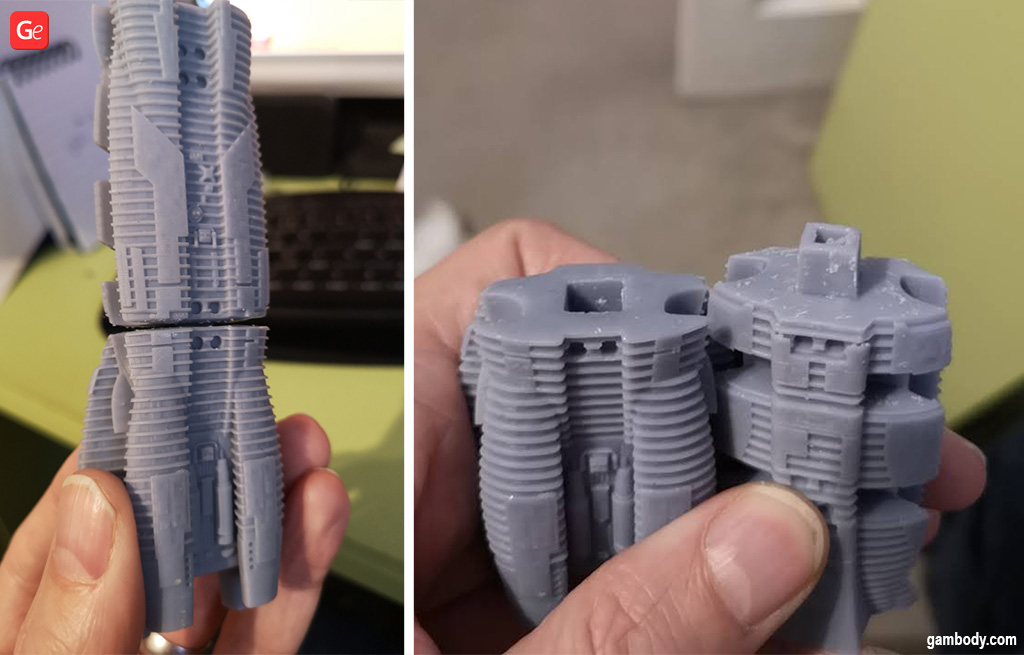

Instance 2. Joker

You possibly can orient the Joker mannequin on the SLA/DLP/LCD 3D printer mattress in nearly the identical place because it was sculpted. Tilt the top backward to keep away from facial SLA help.

You possibly can discover thick 3D print helps on the backside and medium & skinny SLA help buildings nearer to the perimeters. The fill quantity transition is easy all through the venture. It decreases towards the highest, making it simple to 3D print with minimal help density.

Instance 3: Odyssey Spartan Warrior

Please take note of how the elements are situated on the mattress whereas resin printing the Odyssey Spartan Warrior mannequin. The torso has a transition in quantity we mentioned above, however this mannequin is hole and has skinny partitions. So, regardless of the tiny waist and broad shoulders, there are not any vital modifications throughout the print space.

However the issues can be actual if the mannequin was strong. And it appears the writer didn’t rotate the thing to keep away from SLA help buildings in probably the most seen areas.

Arduous floor parts, resembling a flat disc (protect), a stand, or a wheel, should be oriented appropriately on the mattress to make use of 3D printer helps and obtain an impressive 3D print. They need to stay nonetheless all through the SLA/DLP/LCD resin printing course of, so 3D printer helps play a big position.

Most elements are printed at an angle as a result of it’s simpler to use resin helps. You possibly can discover the identical factor in regards to the Spartan head; it’s barely tilted again.

If we selected to orient the elements at a steeper or flatter angle, we might waste numerous resin and devour extra time on resin printing and post-processing.

Instance 4: Racquet

When resin printing a racquet, it’s a good suggestion to tilt it in order that the strings are printed to an angle to the mattress. Such a slope helps print every string extra easily and provides extra SLA help buildings.

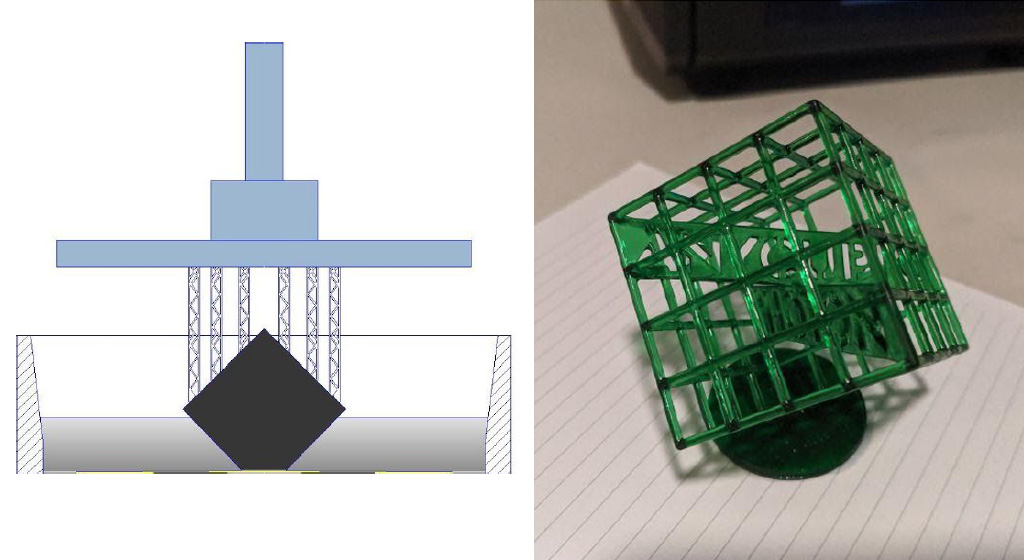

Rule 2: Avoiding Flat Edges Relative to the Printer Mattress

There’s one other drawback you’ll be able to expertise throughout resin printing. Generally you have to print a mannequin with flat faces, and so they don’t prove flat. It occurs as a result of the resin hasn’t utterly dried out and due to the floor pressure of the movie. The excessive tear drive deforms the thing’s lowest half, bending it in the direction of the middle and flipping the perimeters.

But when we tilt the dice by 30 to 60 levels, we are going to keep away from a sizeable bed-adhesive space. The resin printing might be even, leaving a skinny line or a dot on the finish.

You possibly can see how rotating the dice by 30 to 60 levels in each faces goes on the instance of the Photon mannequin that comes with the flash drive together with a 3D printer.

Understanding the distinction between FDM and photopolymer 3D printers (SLA/DLP/LCD) is a should. Resin 3D printers permit constructing the thinnest parts simply, however you’ll be able to expertise vital troubles when making flat and enormous edges.

Due to this fact, if you orient elements for resin printing, you have to keep away from placing flat edges parallel to the mattress. Even tilting them to 10 to fifteen levels can repair the problems.

One other nuance is to help SLA (or DLP/LCD) appropriately. Usually, it is smart to rotate the mannequin by 180 levels, which is healthier seen within the examples under.

Instance 1: Altering the Angle for Battlestar Galactica

One among Gambody’s purchasers complained about getting uneven edges after printing the Battlestar Galactica mannequin vertically. It was printed simply because it was bought on gambody.com, and no changes had been made for resin printing. The floor pressure pulled the highest down, deforming the mannequin and ruining the venture. Gambody suggested to tilt the mannequin and print it at an angle, which turned out completely properly.

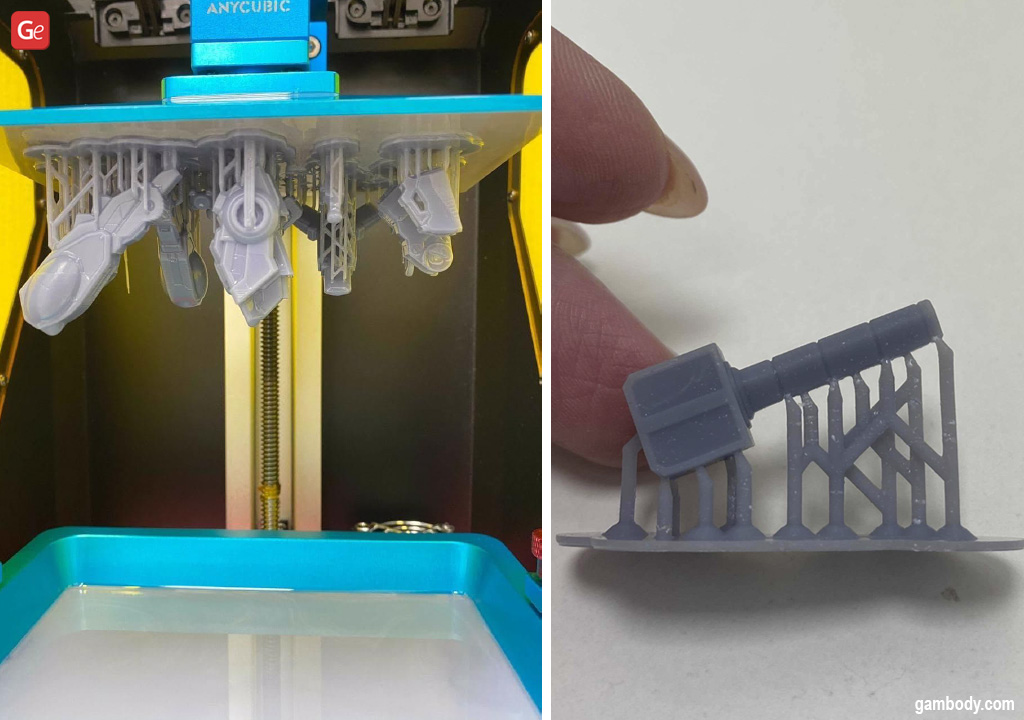

Instance 2: Mech

When resin printing a Mech mannequin, orienting all of the elements to keep away from having flat edges parallel to the 3D printer mattress is crucial. On the similar time, turning a few of the elements is a should to make sure that the amount goes from bigger to smaller.

There is no such thing as a have to rotate the legs the wrong way up as a result of their cross-sectional space doesn’t differ a lot from high to backside, and there’s no level of their rotation.

You can even take note of how the Mech weapon was printed in resin.

Learn additionally: Incredible MechWarrior 3D Print Assortment

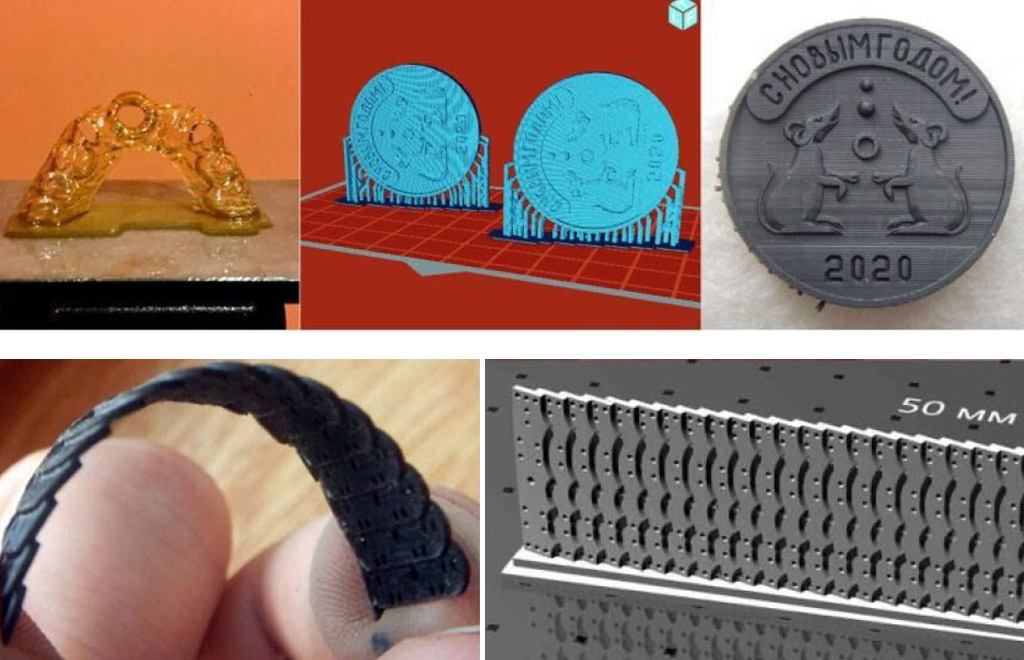

Rule 3: Vertical Resin Printing

Generally you have to resin print vertically. It’s the finest orientation for recreating double-sided cash, tokens, badges, and different vertical fashions. You can even print skinny single-sided objects vertically.

And whereas there can by no means be too many SLA help buildings, it’s best to not overrate whereas printing vertical tasks.

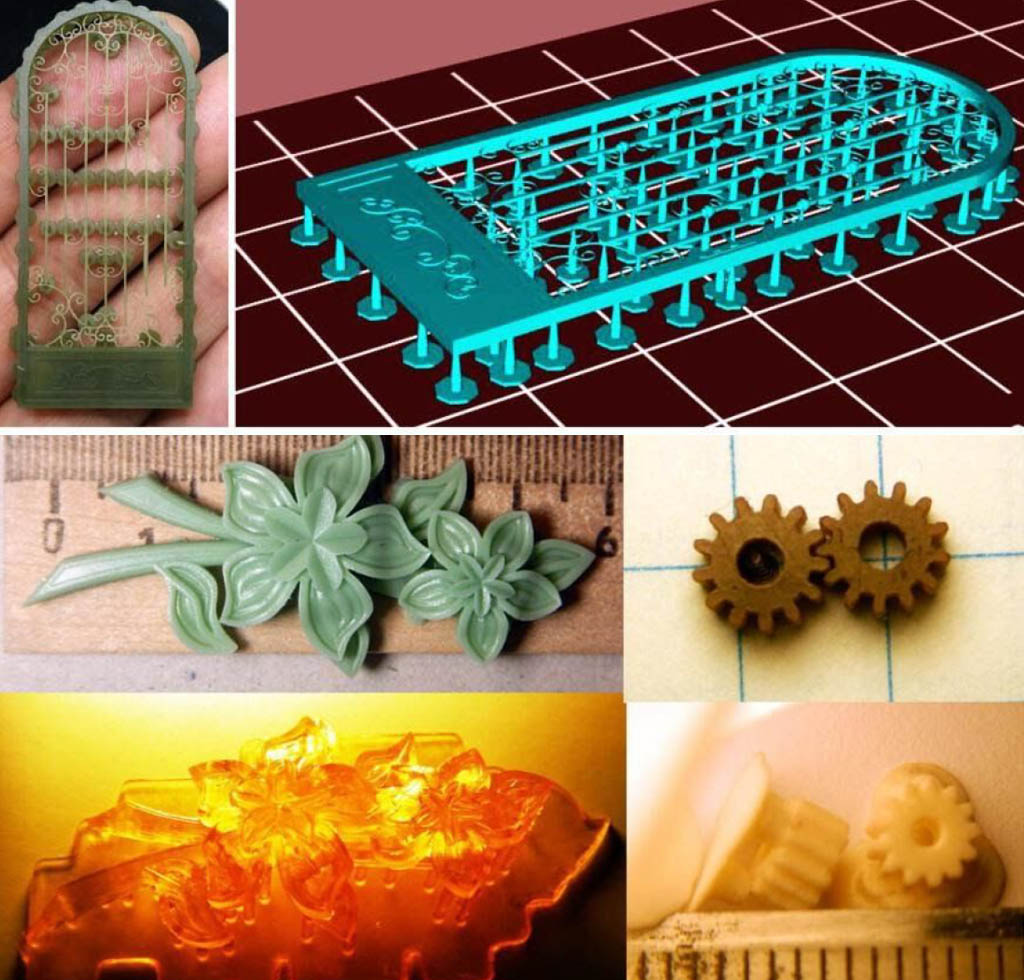

Rule 4: Printing Flat Components with SLA Help

It’s harmful to resin print flat objects “flat on the mattress” due to the large rip-off space. However if you happen to purchase a high-quality resin and don’t care about losing the 3D printing materials, you’ll be able to create incredible tasks this manner. As a bonus, you’ll be able to construct a easy high floor in case your resin is easy.

Instance 1: Detailed Print

Right here is an instance of printing a flat object with low resin helps. In any other case, printing such a fancy and highly-detailed venture can be unattainable.

Instance 2: Brooch

Have a look at one other pattern of flat resin printing utilizing low SLA help. The brooch was printed flat as a result of it has a gap for attaching the brooch pin.

As for the gears, they may have been printed proper on the mattress with no 3D printer helps if they’d a smaller base to compensate for the growth of the primary layers.

Such an orientation has its disadvantages for resin printing. We’re speaking in regards to the quality-specific aspect of the mannequin from the place SLA help buildings are used. This reverse aspect will be okay, even easy, however lots is determined by the print mannequin, 3D printing materials, resin movie, help density, and many others.

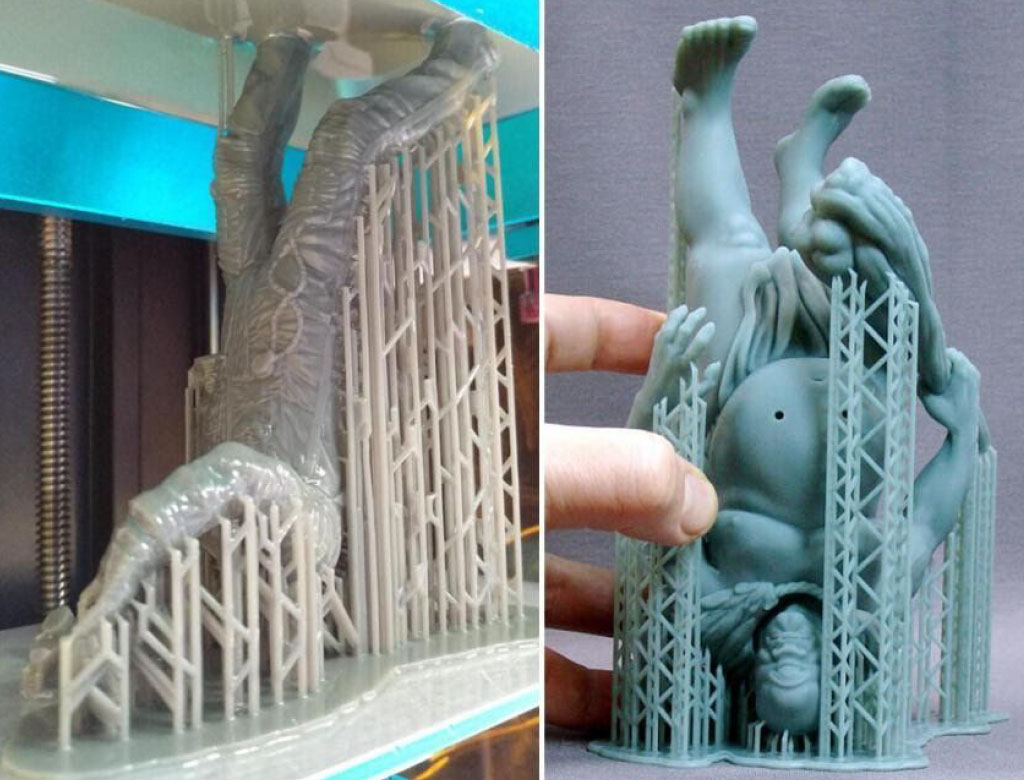

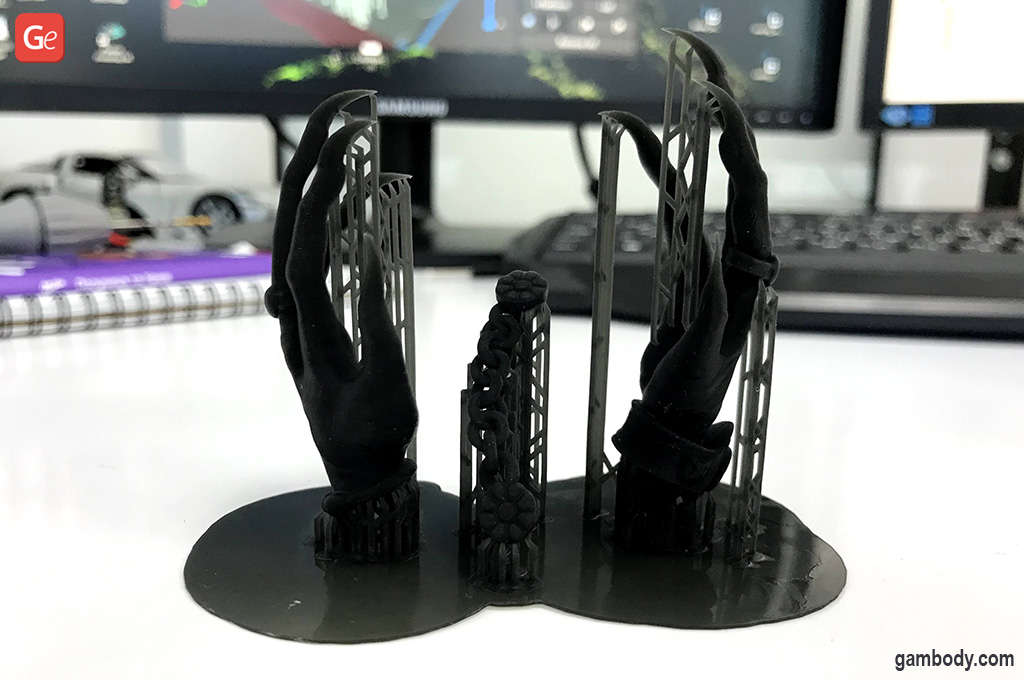

Rule 5: Upside-Down Prints

Normally, animal and character fashions have many particulars lowered down that require resin helps. It’s usually sufficient to rotate the thing the wrong way up and add SLA help for the top or neck to simplify the printing.

If you print a personality head with hair, it’s finest to place it with hair strands dealing with up. If you print character arms, orient them with fingers dealing with up. If you print garments, be sure that the underside hem is dealing with up.

These are actually not all secrets and techniques of mannequin orientation for resin printing on SLA/DLP/LCD 3D printers. Loads is determined by your expertise and checks. We hope this was useful to you, and good luck on respiratory life into new Gambody fashions!

(Visited 19 occasions, 1 visits as we speak)